Threading guide device for double-end crimping

A technology of guiding device and crimping device, which is applied in the direction of connection, line/collector parts, electrical components, etc., which can solve the problems that the crimping surface of the terminal cannot be guaranteed, affects the appearance, and is labor-intensive, etc., and achieves automatic feeding Action, solve the interference of the position, improve the effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

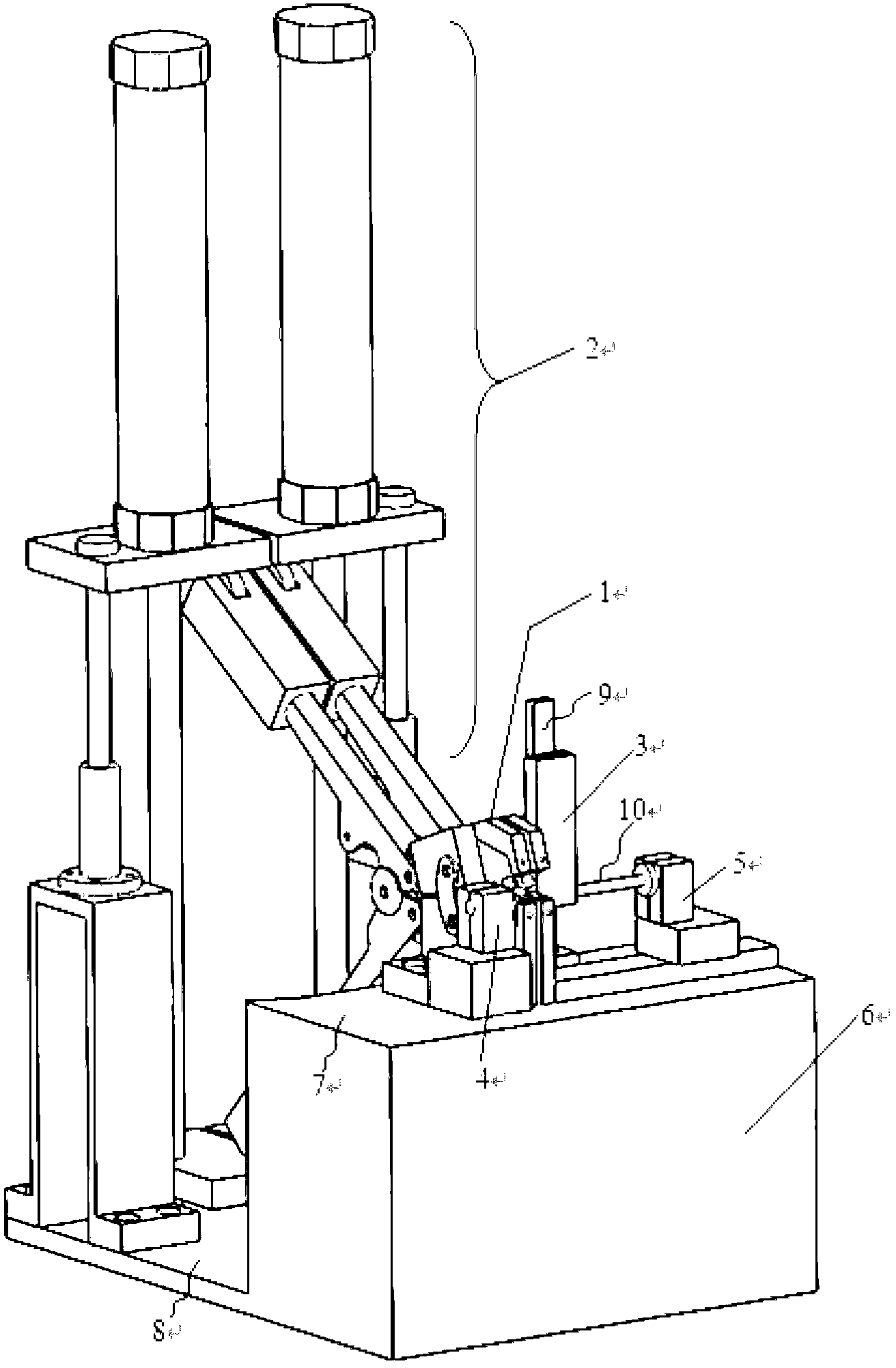

[0015] The process of double-ended terminal crimping is simply to put the two ends of the double-ended terminal through the wires for crimping. The present invention relates to a double-end crimping device, such as figure 1 As shown, the pliers assembly 1 adopts a left-right symmetrical layout to realize simultaneous crimping at both ends, the clamp arm assembly 2 and the drive assembly 3 cooperate to realize automatic crimping, and the terminal box assembly 3 is cleverly designed to automatically feed materials; and in order to realize the automatic crimping process Both ends can be threaded at the same time, and the present invention provides a threading guide device, which includes two sets of threading guide assemblies.

[0016] The implementation process in which the device of the present invention is applied to double-end crimping is described in detail below:

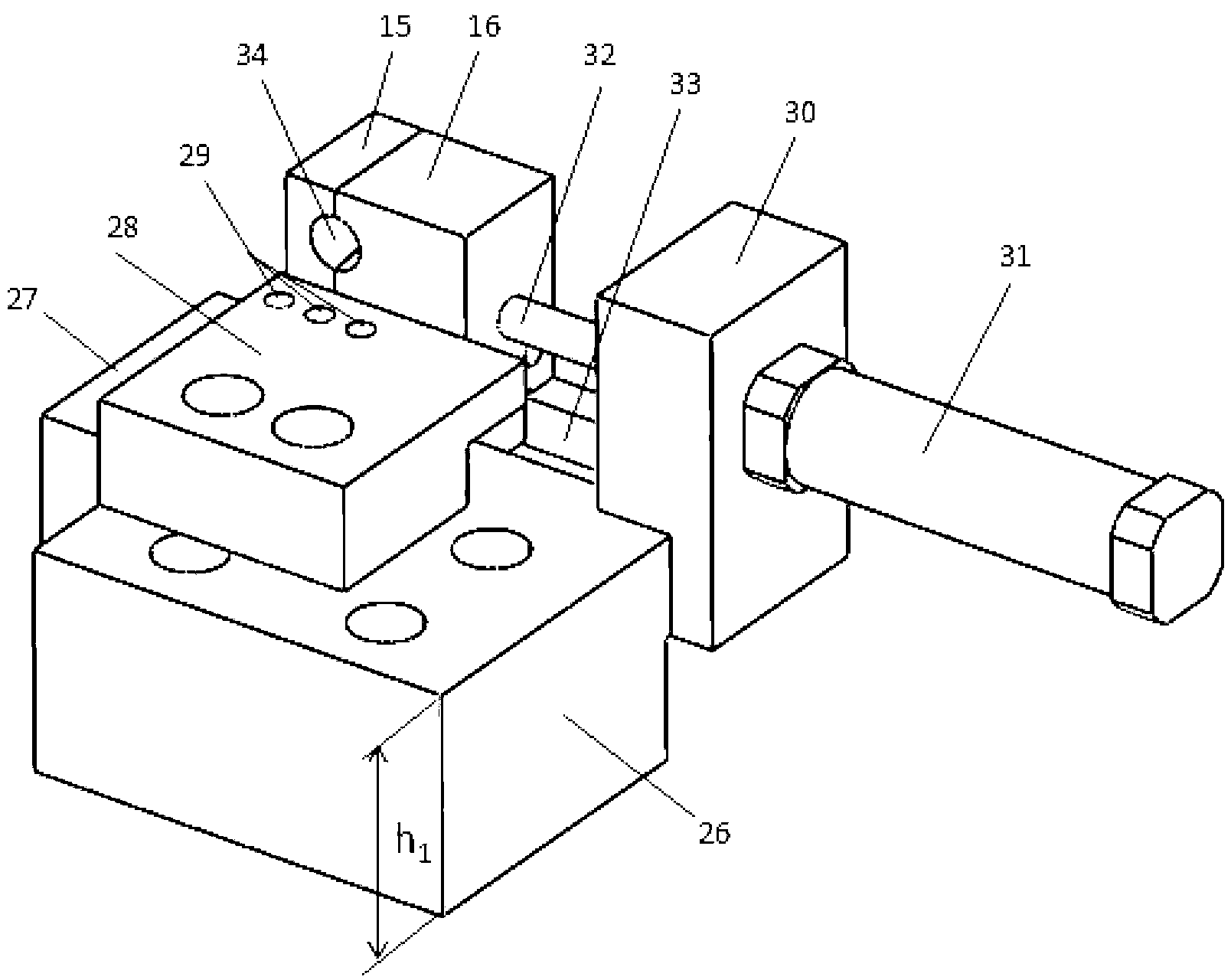

[0017] Such as image 3 As shown, a threading hole block adjustment plate 27 is fixed behind the threading ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com