Three-level inverter dead time compensation control method

A three-level inverter and dead zone compensation technology, which is applied to electrical components, AC power input to DC power output, output power conversion devices, etc. Problems such as pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

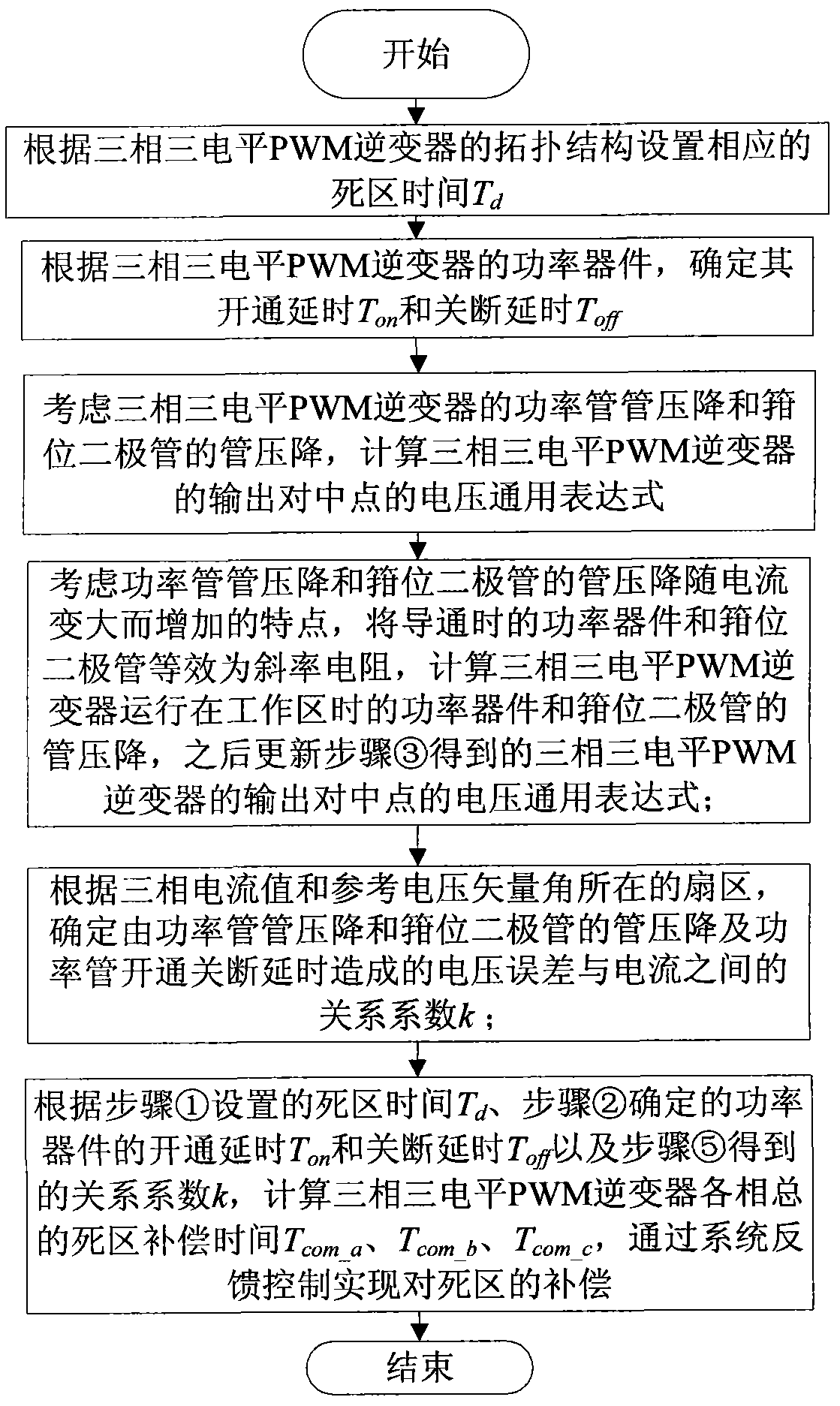

[0113] A dead zone compensation control method for a three-level inverter, such as figure 1 As shown, the specific steps are:

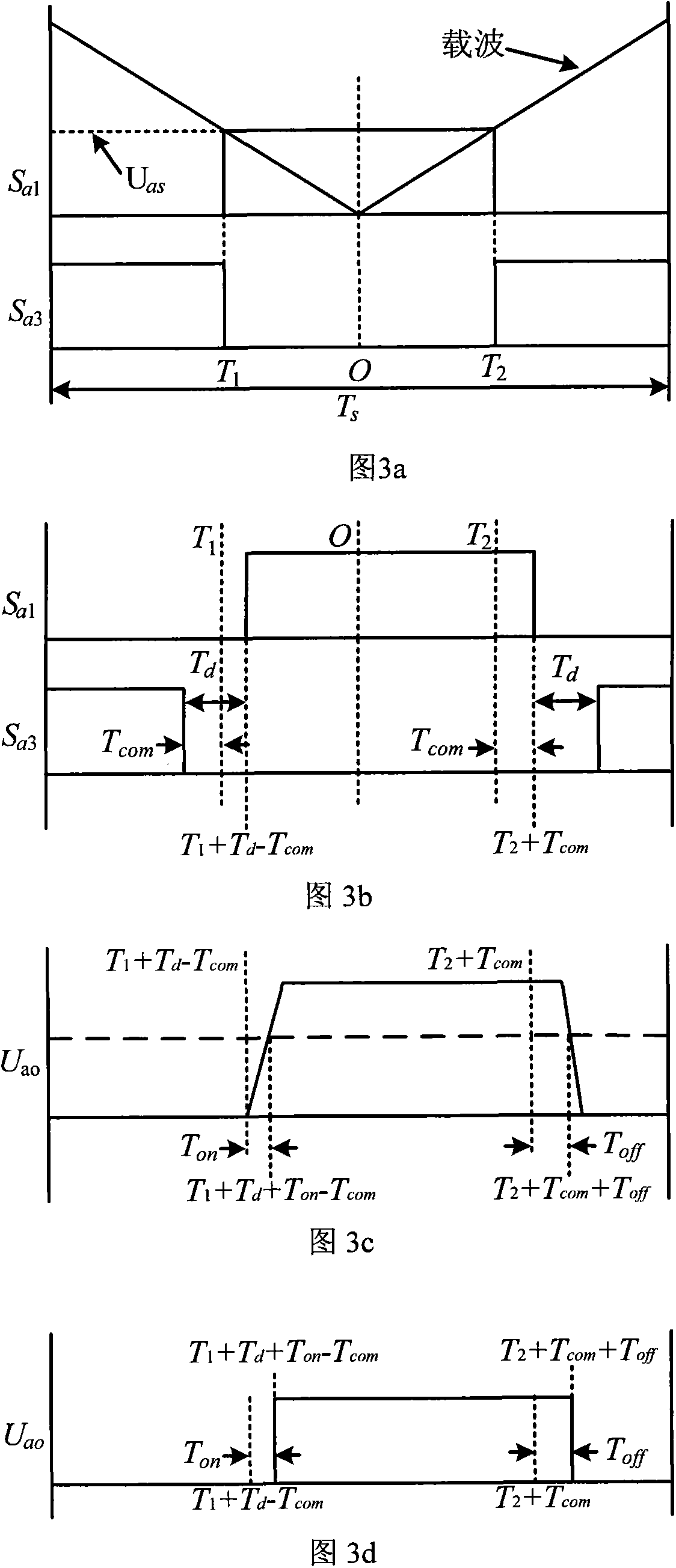

[0114] ① According to the topology structure of the three-phase three-level PWM inverter, considering the delay time for the switch device to be completely turned off, this embodiment sets the corresponding dead time T d = 10μs;

[0115] ② According to the power device of the three-phase three-level PWM inverter, determine its turn-on delay T on = 7μs and turn-off delay T off = 7μs;

[0116] ③Considering the power tube voltage drop of the three-phase three-level PWM inverter and the tube voltage drop of the clamping diode, calculate the general expression of the output midpoint voltage of the three-phase three-level PWM inverter;

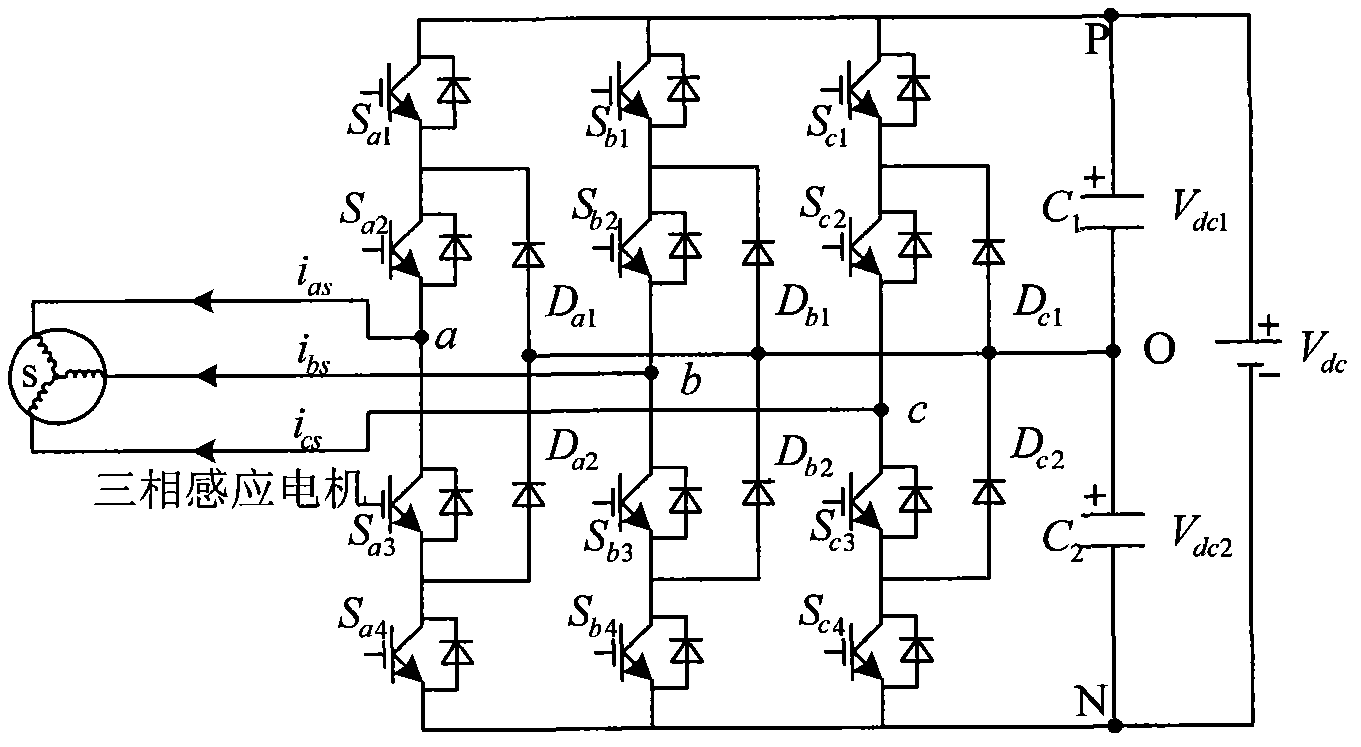

[0117] Such as figure 2 As shown, taking phase A as an example, when i as When >0, the voltage of the actual output point a to the midpoint O is

[0118] V ao = ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com