Environmental energy conversion device

An energy conversion and environmental technology, applied in electrical components, generators/motors, etc., to solve problems such as disorder, consumption of mechanical energy, hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

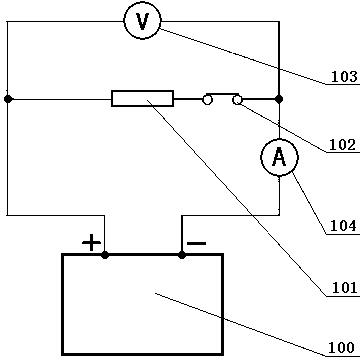

[0052] Embodiment 1, platinum-gold-purified water test

[0053] Wherein, the anode body 1 is made of platinum, the anode body 2 is made of gold, and the droplet as the intermediary body is made of pure water. At an ambient temperature of 25°C, the open circuit voltage obtained by the test is 205 mV, and the current obtained after loading a 400 kΩ load is 0.21 μA, and the calculated internal resistance is 565 kΩ.

Embodiment 2

[0054] Embodiment 2, platinum-gold-sodium chloride aqueous solution test

[0055] Replace the above pure water with an aqueous solution of NaCl with a concentration of 1 mole per liter. At an ambient temperature of 25°C, the open circuit voltage obtained by the test is 0.21 V, and the current obtained after loading a 400 kΩ load is 0.34 μA, and its internal resistance is calculated. is 220 kΩ.

[0056] The design of the structure is mainly to facilitate the integration of this energy conversion device, making the patent of the present invention oriented to industrial production. It is well known to those skilled in the art that other film-body, film-film, body-body system power generation devices in electrolyte solution other than the above-mentioned Examples 1 and 2 are within the protection scope of this patent.

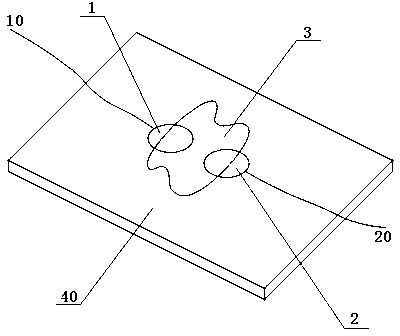

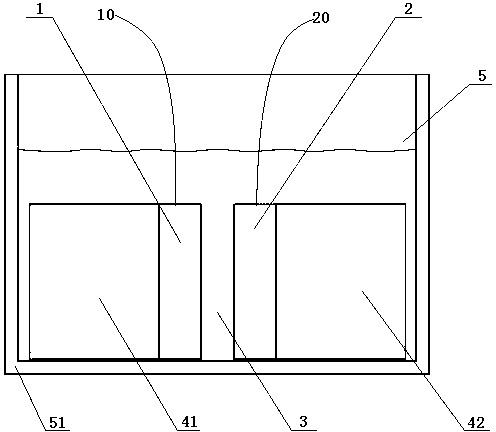

[0057] 2. Film-film test

[0058] 1. Film-film test structure

[0059] An environmental energy conversion device includes an energy conversion unit. energy con...

Embodiment 3

[0062] Embodiment 3, the test of long-time current output

[0063] CuCl as intermediary 3 2 The concentration of the aqueous solution is 5 moles per liter, the temperature of the solution is 25°C, and the open circuit voltage is 0.5 V according to the test. In the case of loading a 400 kΩ load between the positive and negative electrodes, the relationship between the output current and time of the environmental energy conversion device within 100 hours of testing is as follows Figure 4 shown. Depend on Figure 4As shown, in this embodiment, after 48 hours, the current output is basically stable at about 1.14 microamperes, and the calculated internal resistance is about 40 kΩ.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com