Gasoline desulfurization catalyst and preparation method thereof and gasoline desulfurization method

A desulfurization catalyst and gasoline technology, applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of poor regeneration of adsorbents, large loss of gasoline liquid, and can not be used to produce oil products with low sulfur content and other problems, to achieve the effect of less olefin saturation and less loss of gasoline octane number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

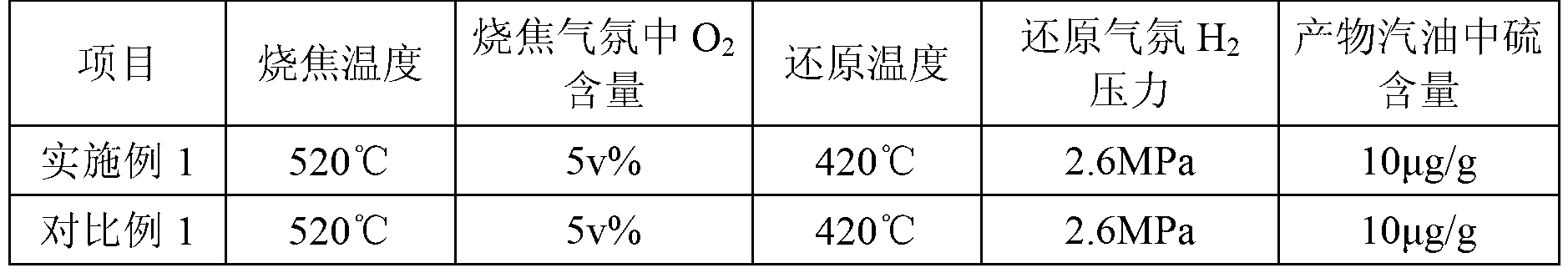

Embodiment 1

[0040] This embodiment provides a gasoline desulfurization catalyst, which is prepared by the following method:

[0041] Add 1 gram of potassium chloride (chemically pure, manufactured by Beijing Chemical Reagent Company) and 300 grams of nickel nitrate hexahydrate (chemically pure, manufactured by Beijing Chemical Reagent Company) into 1 liter of water for dissolution to obtain an acidic aqueous solution;

[0042] 200 grams of basic zinc carbonate (chemically pure, manufactured by Beijing Chemical Reagent Company) was roasted in a muffle furnace at 400° C. for 2 hours and then cooled to form zinc oxide. The hydrogen sulfide adsorption sulfur capacity of the zinc oxide was measured to be 30% by weight;

[0043] Add 100 grams of aluminum hydroxide (industrial grade, manufactured by Shandong Aluminum Factory, solid content is 63% by weight) into the acidic aqueous solution and grind it evenly, then add 50 grams of SAPO-11 molecular sieve (industrial product, manufactured by Nanka...

Embodiment 2

[0046] This embodiment provides a gasoline desulfurization catalyst, which is prepared by the following method:

[0047] 2 grams of potassium nitrate (manufacturer and purity are the same as in Example 1) and 300 grams of nickel nitrate hexahydrate (manufacturer and purity are the same as in Example 1) are added to 4 liters of water and dissolved to obtain an acidic aqueous solution;

[0048] After 220 grams of basic zinc carbonate (manufacturer and purity are the same as in Example 1) were roasted in a muffle furnace at 450° C. for 1 hour and cooled, zinc oxide was formed, and the hydrogen sulfide adsorption sulfur capacity of the zinc oxide was measured to be 27% by weight;

[0049] Add 100 grams of aluminum hydroxide (industrial grade, manufactured by Shandong Aluminum Plant, solid content is 65% by weight) into the acidic aqueous solution and beat evenly, then add 40 grams of ZSM-5 molecular sieve (industrial product, manufactured by Nankai University Catalyst Factory, The...

Embodiment 3

[0052] This embodiment provides a gasoline desulfurization catalyst, which is prepared by the following method:

[0053] 1 gram of potassium sulfate (manufacturer and purity are the same as in Example 1) and 300 grams of nickel nitrate hexahydrate (manufacturer and purity are the same as in Example 1) are added to 1 liter of water and dissolved to obtain an acidic aqueous solution;

[0054] After 210 grams of basic zinc carbonate (manufacturer and purity are the same as in Example 1) were roasted in a muffle furnace at 350° C. for 3 hours and cooled, zinc oxide was formed, and the hydrogen sulfide adsorption sulfur capacity of the zinc oxide was measured to be 31% by weight;

[0055] Add 100 grams of aluminum hydroxide (industrial grade, manufactured by Shandong Aluminum Plant, solid content of 65% by weight) into the acidic aqueous solution and grind it evenly, then add 45 grams of ZSM-5 molecular sieve (industrial product, manufactured by Nankai University Catalyst Factory, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap