Atomization unit

A micronization and nozzle device technology, applied in the direction of grain processing, etc., can solve the problems of difficulty in obtaining the particle size distribution of crushed raw materials, large dead volume of the device, and impurities mixed in, so as to improve the efficiency of micronization treatment, reduce dead volume, and improve The effect of shear force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

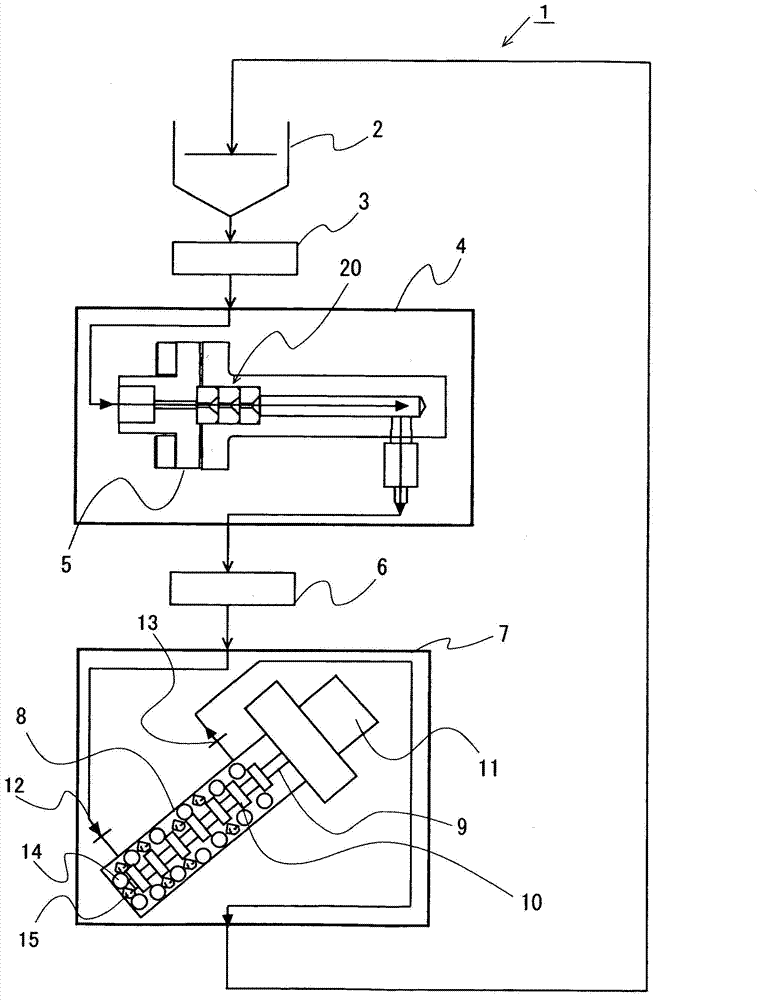

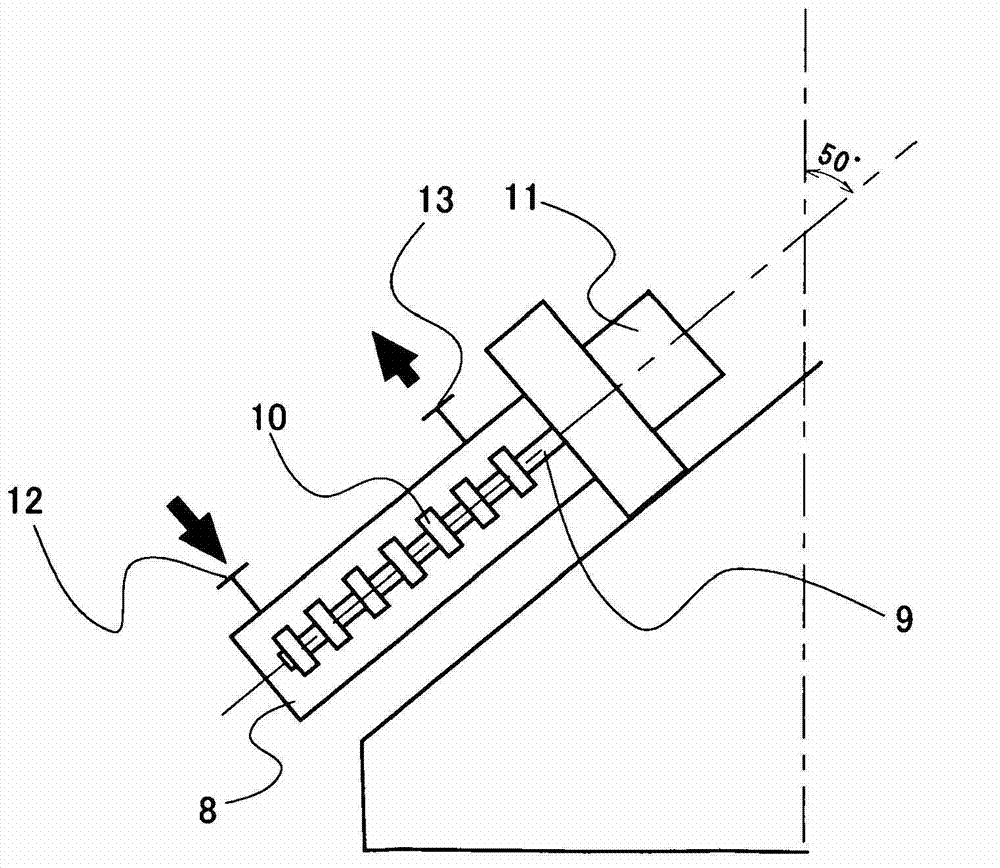

[0058] As an embodiment of the present invention, figure 1 It refers to a micronization device that connects a jet mill and a bead mill in one line and combines them with the same series circulation circuit for the raw material tank. In the jet mill of the present embodiment, a jet mill including a single nozzle device having three throttle nozzles is shown.

[0059] This micronization device 1 is mainly a micronization device in which the wet jet mill 4 and the bead mill 7 are connected to the raw material tank 2 by the same series circulation loop and connected on one line. In this circuit structure, the slurry in the raw material tank 2 is transported to the jet mill 4 through the liquid supply pump 3 and sprayed at a high speed by the nozzle device 5 . The sprayed slurry is cooled by the heat exchanger 6, then introduced into the bead mill 7, and returned to the raw material tank 2 after being processed.

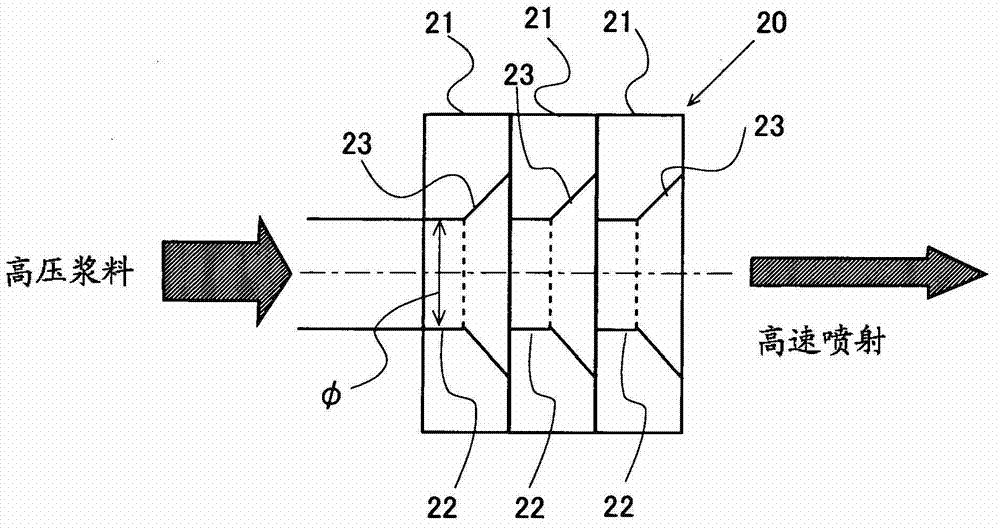

[0060] Jet mill 4 in the present embodiment is such as figure 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com