Intelligent iron ore concentrator

A technology for concentrating machines and iron ore, applied in the fields of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of large water consumption, large equipment volume, complex structure, etc., to achieve easy installation and maintenance, large processing capacity , the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

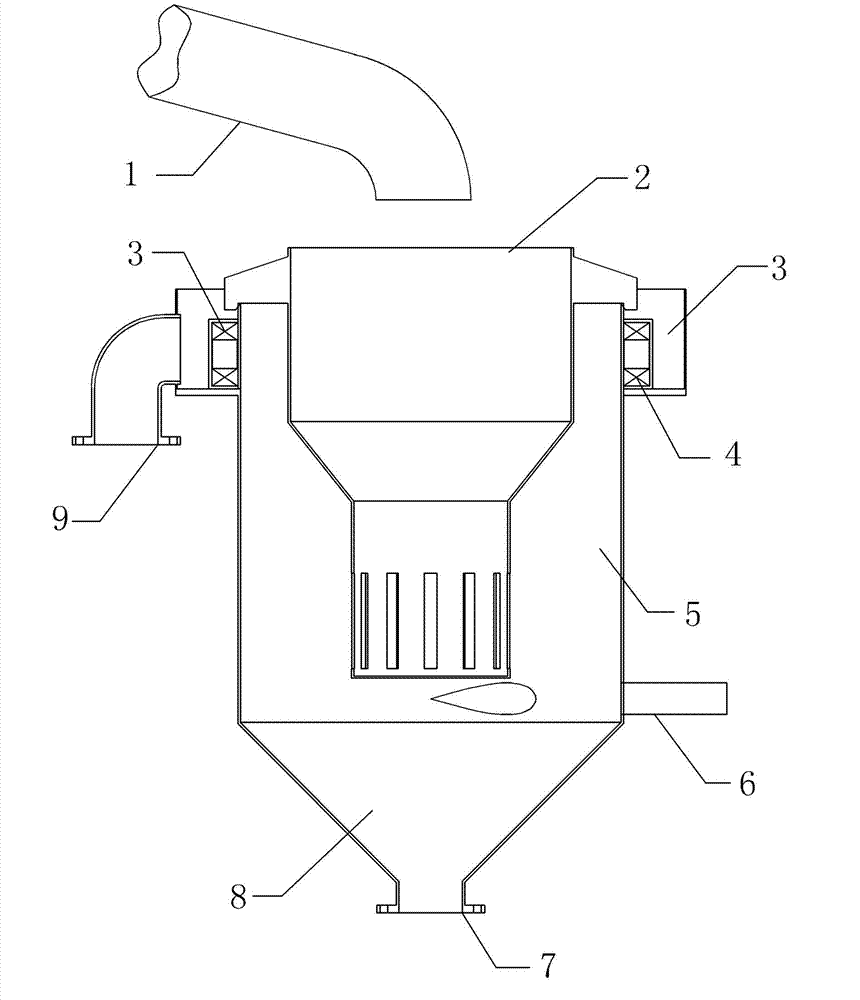

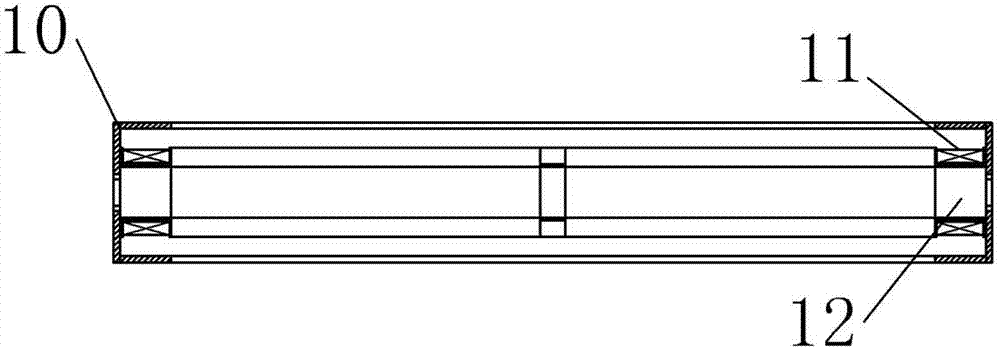

[0017] As shown in the figure, the intelligent iron ore concentrator includes an ore feeding pipe 1, an ore feeding tube 2, an outer shell 8 and an overflow chamber 3; the ore feeding tube 2 is fixedly embedded in the outer shell 8, and its outer wall and the outer shell The inner wall of the body 8 forms a swirl area 5; the outlet of the ore feeding pipe 1 corresponds to the entrance of the ore feeding tube 2; at the lower part of the outer shell 8, a water supply pipe 6 is fixedly installed corresponding to the outlet area of the ore feeding tube 2; The overflow cavity 3 communicates with the swirling flow area 5; the electromagnetic system 4 is arranged in the circumferential direction of the overflow cavity 3 to form a convergent magnetic field.

[0018] In the present invention, a cone-shaped settlement area is fixedly provided at the bottom of the outer casing 8 . The cylinder diameter of the ore feeding cylinder 2 of the present invention decreases successively along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com