Composite insulation board production line

A composite thermal insulation and production line technology, which is applied in ceramic molding workshops, ceramic molding machines, manufacturing tools, etc., can solve the problems of not producing composite thermal insulation boards, etc., and achieve high equipment utilization, high product quality, and high degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

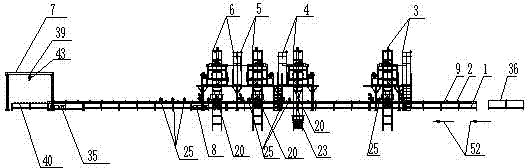

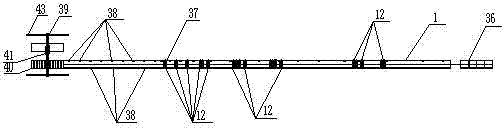

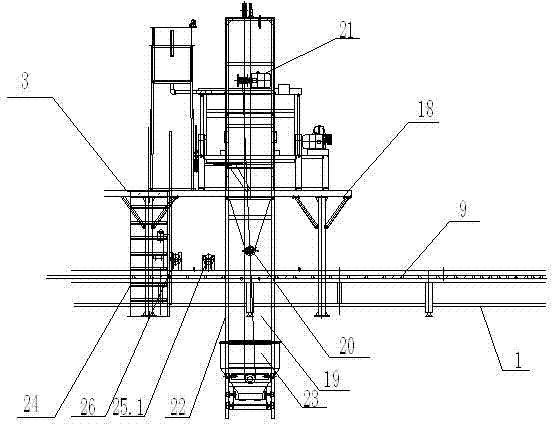

[0024] Below in conjunction with accompanying drawing, the present invention will be further described:

[0025]Accompanying drawing is a kind of specific embodiment of the present invention, and this embodiment comprises production line frame body 1, and described production line frame body 1 is provided with conveying device 2, and described production line frame body 1 is provided with the following in sequence according to the same direction. Feeding device I3, feeding device II4, feeding device III5 and feeding device IV6, the end of the frame body 1 of the production line adjacent to the feeding device IV6 is provided with a mobile hanger device 7, and the two ends of the feeding device I3 The side is equipped with a grid cloth device, and a grid cloth device is provided between the unloading device II4 and the unloading device III5, and the two sides of the unloading device IV6 are provided with a grid cloth device. The production line frame body 1 A plurality of scrapi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com