Waterproof adhesive prepared from a plurality kind of industrial residue and liquid waste

A technology of industrial waste residue and adhesive, applied in the direction of adhesive, adhesive type, asphalt material adhesive, etc., can solve the problems of raw material waste, environmental pollution, etc., achieve huge economic and social benefits, reduce environmental pollution, and the preparation method is simple Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

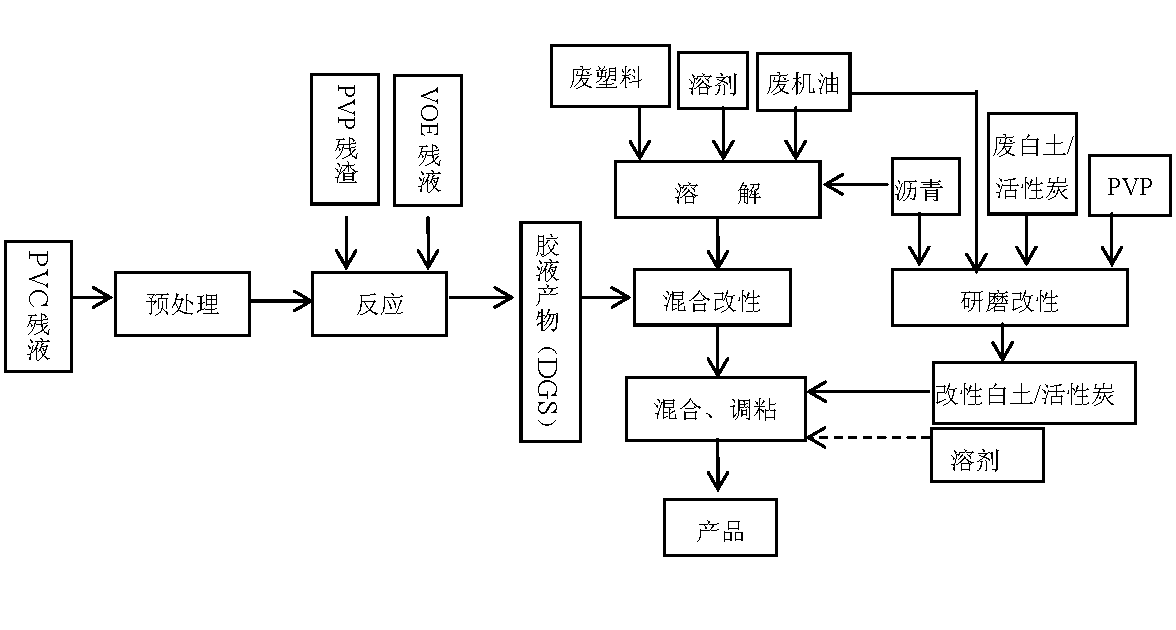

Method used

Image

Examples

Embodiment 1

[0022] In concrete implementation, the present invention is realized by the following steps:

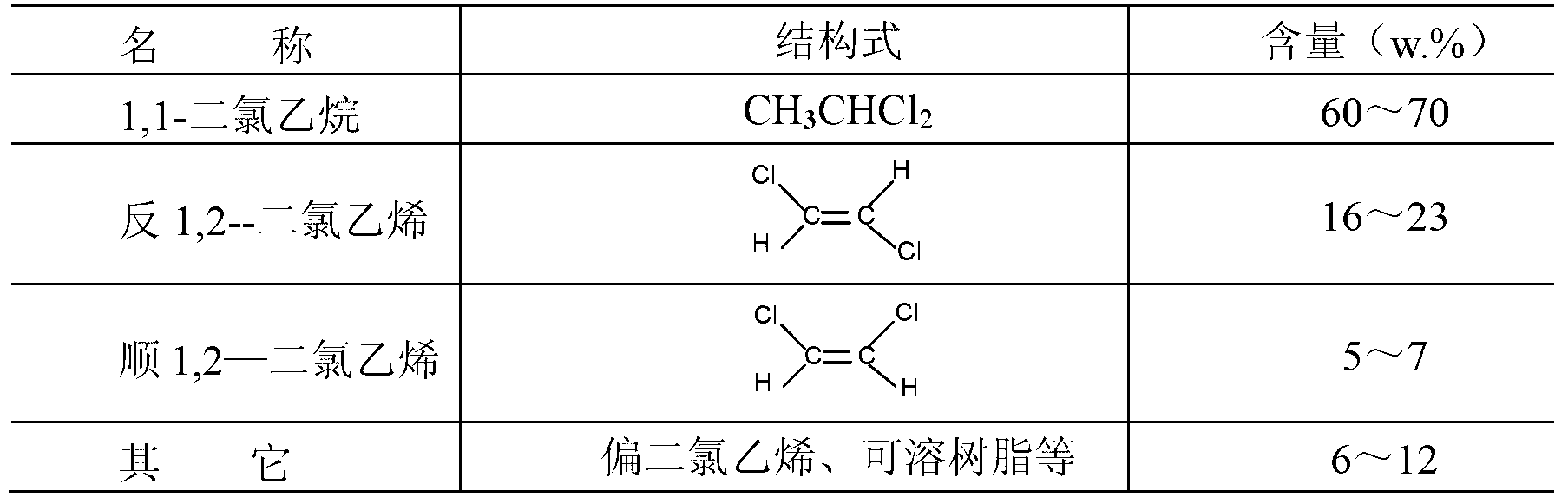

[0023] (1) Pretreatment of PVC residue: remove water from the PVC residue to obtain a brownish-red PVC residue pretreatment solution with a specific gravity of 1.1g / ml, the main components of which are:

[0024]

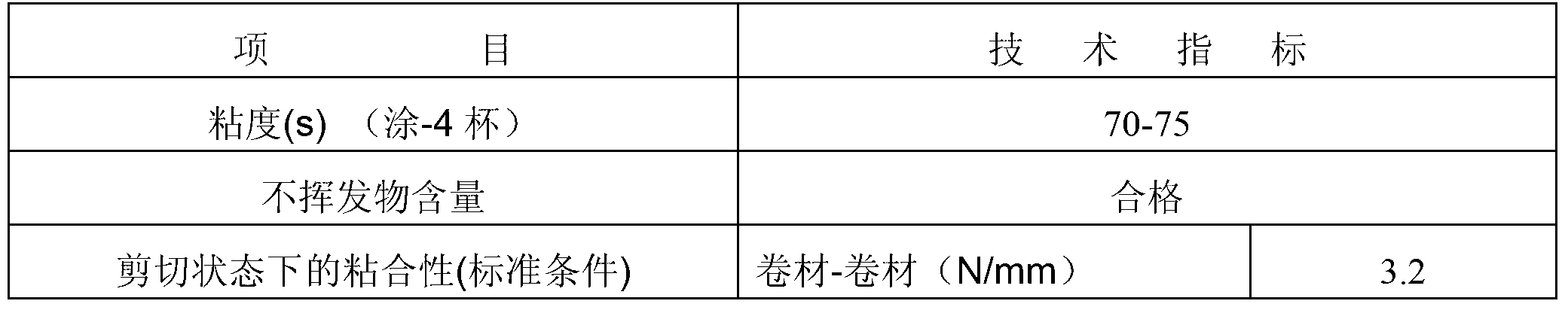

[0025] (2) Preparation of multi-component copolymer resin glue (DGS): The method is, by weight: PVC residual liquid pretreatment liquid 35%, PVP residual liquid 35%, VOE residual liquid 25%, initiator azobisisobutyronitrile ( AIBN) solution of 5%, wherein the VOE residue and PVP residue are added to the PVC residue pretreatment liquid, stirred and mixed evenly, and the temperature is raised to 70-75°C, and the initiator azobisisobutyronitrile solution is added dropwise. , 1.5 hours to complete the dropwise reaction for 1.5 hours at the same time, then raise the temperature to 80°C, and continue the reaction for 2-2.5 hours to obtain multi-component copolymer resin glue (...

Embodiment 2

[0029] In concrete implementation, the present invention can be realized by the following steps:

[0030] (1) Pretreatment of PVC residue: remove water from the PVC residue to obtain a brownish-red PVC residue pretreatment solution with a specific gravity of 1.08g / ml;

[0031] (2) Preparation of multi-component copolymer resin glue (DGS): The method is, by weight: PVC residual liquid pretreatment liquid 44%, PVP residual liquid 28%, VOE residual liquid 24%, initiator azobisisobutyronitrile ( AIBN) solution 4%, in which the VOE residue and PVP residue are first added to the PVC residue pretreatment solution, stirred and mixed evenly, and then the initiator azobisisobutyronitrile solution is added dropwise, and the temperature is first raised to 70-75°C , start to add the initiator azobisisobutyronitrile solution dropwise, finish the dropwise addition in 1.5 hours and react for 1.5 hours at the same time, then raise the temperature to 85°C, and continue the reaction for 2 hours ...

Embodiment 3

[0035] The present invention also can be realized by following steps:

[0036] (1) Pretreatment of PVC residual liquid: remove water from the PVC residual liquid to obtain a brownish-red PVC residual liquid pretreatment solution with a specific gravity of 1.12g / ml;

[0037] (2) Preparation of multi-component copolymer resin glue (DGS): The method is, by weight: PVC residual liquid pretreatment liquid 40%, PVP residual liquid 33.5%, VOE residual liquid 23%, initiator azobisisobutyronitrile ( AIBN) solution 3.5%, in which VOE residue and PVP residue are added to the PVC residue pretreatment liquid, stirred and mixed evenly, and then the initiator azobisisobutyronitrile is added dropwise, and the temperature is first raised to 70-75°C. Start to add the initiator azobisisobutyronitrile solution dropwise, complete the dropwise addition in 1.5 hours and react for 1.5 hours at the same time, then raise the temperature to 83°C and continue the reaction for 2.2 hours to obtain multi-co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap