Assembling highway steel bridge transporting and erecting vehicle

An erection vehicle and assembly technology, applied in the erection/assembly of bridges, bridge construction, bridges, etc., can solve the problem that the handling equipment cannot fully meet the needs of the project, and achieve the effect of improving work efficiency, easy loading and unloading, and beautiful appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

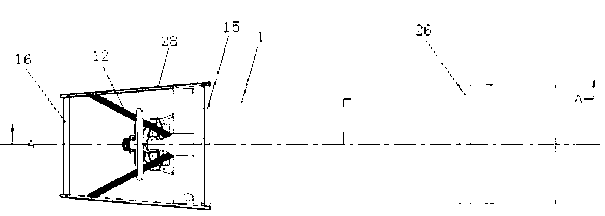

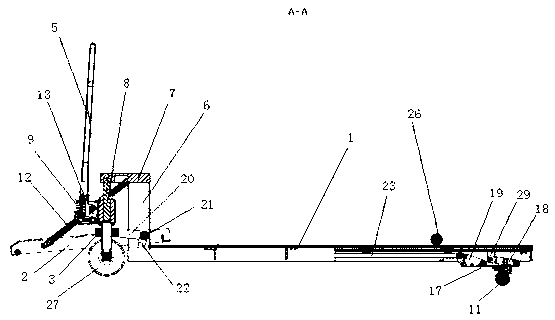

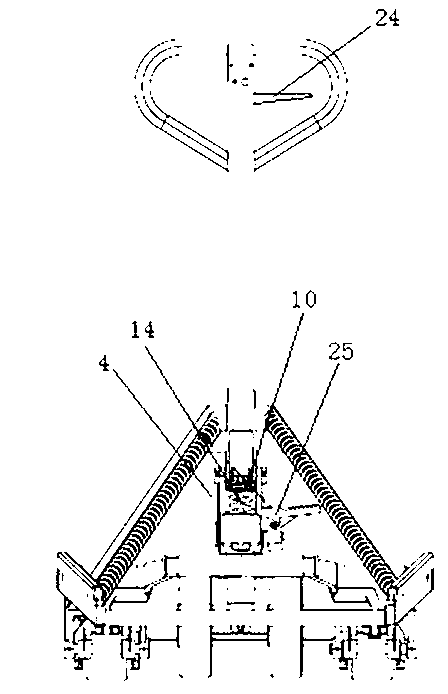

[0040] The assembled highway steel bridge handling and erecting vehicle includes a shelf 1 and a pedal 2, an oil cylinder base 3, an oil cylinder 4 located on the oil cylinder base 3, and a handle 5 hinged to the top of the oil cylinder 4; the shelf 1 is fixed with a vertical plate 6 , the vertical plate 6 is fixed with a top plate 7, and the vertical plate 6 is connected with the oil cylinder base 3 through two A connecting pieces 20 on the left and right; the oil cylinder 4 includes a large plunger 8 and a small plunger 9, and the large plunger 8 Connected with the top plate 7, the top of the small plunger 9 is in contact with the bottom of the handle 5; the lower end of the oil cylinder base 3 is provided with a rear wheel 27, and both sides of the front end of the shelf 1 are respectively provided with a universal wheel 11; The front wheel 11 is connected with the front wheel cross plate 17, and the front end of the front wheel cross plate 17 is hinged with the front wheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com