Connection structure of integrally assembled concrete frame and shear wall

A technology for connecting structures and concrete, applied in the direction of walls, building components, building structures, etc., can solve the problems of difficult control of steel bar alignment, many steel bar sleeves, and time-consuming connection, etc., and achieves low cost, easy lifting and construction. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

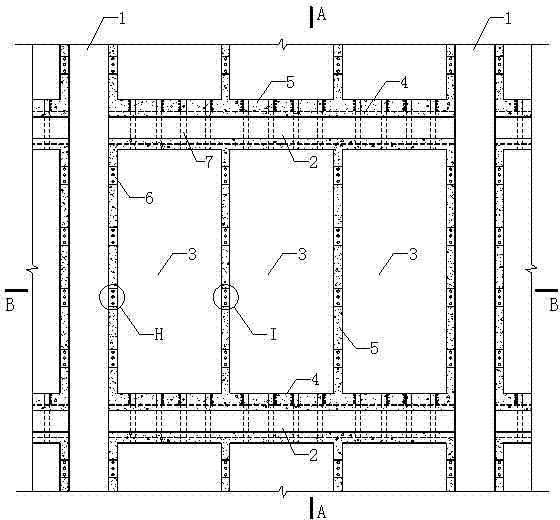

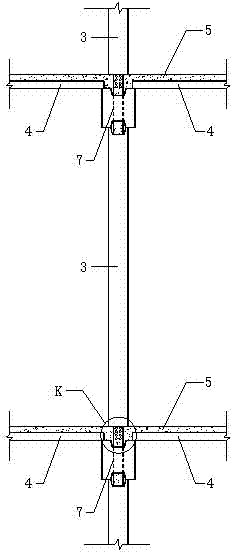

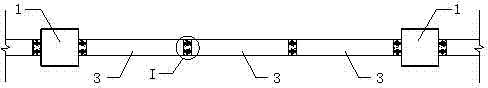

[0030] Referring to the accompanying drawings, an assembled integral concrete frame-shear wall connection structure includes precast concrete columns 1, precast H-shaped concrete composite beams 2, precast concrete shear wall walls 3, precast concrete composite floors 4, Π-shaped horizontal connector 6, channel steel 7, bolt 12, bolt sleeve 11 and post-cast concrete 5, the bolt sleeve is fixedly arranged in the precast concrete column,

[0031] The Π-shaped horizontal connectors (8, 9, 10) include a web 14 and two flange plates 15, the flange plates 15 are perpendicular to the web 14 and fixedly connected by welding, and the flanges The edge plate 15 has an oval hole.

[0032] The prefabricated H-shaped concrete composite beam 2 is also provided with an upper rebate 17 and a lower rebate 18, and the concrete shear wall body is also provided with a corresponding rebate, and the upper rebate 17 of the prefabricated H-shaped concrete composite beam The cross-section is funnel-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com