Construction method for repairing tunnel collapse through insertion pipe grouting

A construction method and intubation technology, which are applied in tunnels, tunnel linings, earthwork drilling, etc., can solve the problems of rock wall collapse and landslides, affecting tunnel safety, tunnel collapse, etc., achieving high work efficiency, strong operability, Use safe and reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

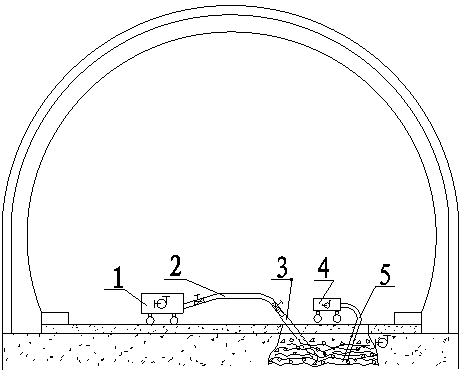

[0019] As shown in the figure: the device in the construction method for repairing tunnel collapse by intubation grouting of the present invention is mainly composed of a high-pressure grouting pump 1, a delivery pipe 2, a porous intubation pipe 3, a mud suction pump 4, and a suction pipe 5.

[0020] High-pressure grouting pump 1: The main function is to pressurize the stirred mud and transport it to the porous cannula 3 through the delivery pipe 2.

[0021] Conveyor pipe 2: High pressure resistant rubber is used, the inner diameter of the pipe is generally between 40mm and 50mm, and the working pressure can withstand 10MPa.

[0022] Porous cannula 3: The cannula is made of metal, and one end is an inner and outer threaded part, which is used to firmly connect with the delivery tube 2. The inner end is in a round closed cone shape to prevent the tube head fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap