Low-noise electric centrifugal pump

A centrifugal pump, electric technology, applied in electric components, pumps, pump devices, etc., can solve the problem of high noise of centrifugal pumps, and achieve the effect of inhibiting inlet backflow, good heat removal effect, and increasing service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

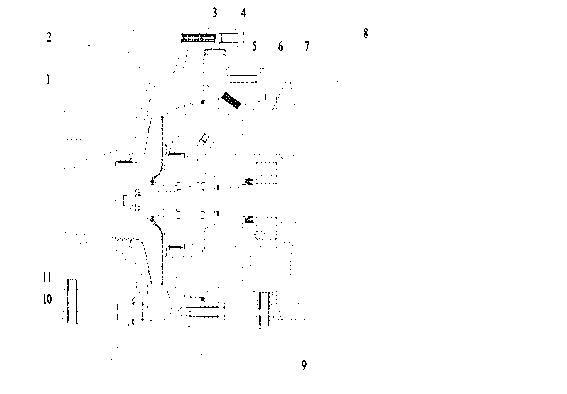

[0017] During the operation of the electric pump, the impeller 1 rotates to generate a head, the outlet of the pump body 2 is high pressure, and the inlet is low pressure. Drainage holes are opened on the outlet flange of the centrifugal pump. The flow channel of the outlet flange of the high-pressure water pump passes through the filter screen 3 and enters the decompression pipe 5 for decompression. A dredging screw 4 is added to the drainage hole to facilitate cleaning. The decompressed water is introduced into the motor condensing system, and its flow rate is controlled by the connected throttle valve 6. The throttle valve 6 is connected to the first bearing cooling chamber 7 through a conduit, and the depressurized water enters the condensing motor casing 8 through the first bearing cooling chamber 7 through the inlet 16, and forms a double "S" shape with the copper pipe 14 Flow around the motor housing removes heat. The housing is made of aluminum, the copper tube 14 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com