Kalina coupling power generation system and process based on solar amino thermochemical energy storage

A technology of solar amino and power generation system, applied in the field of new energy and Karina cycle power generation, can solve the problems of low endothermic temperature, increase of irreversible loss, increase of temperature difference, etc., to improve cycle efficiency, reduce irreversible heat loss, improve Effect of Turbine Back Pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

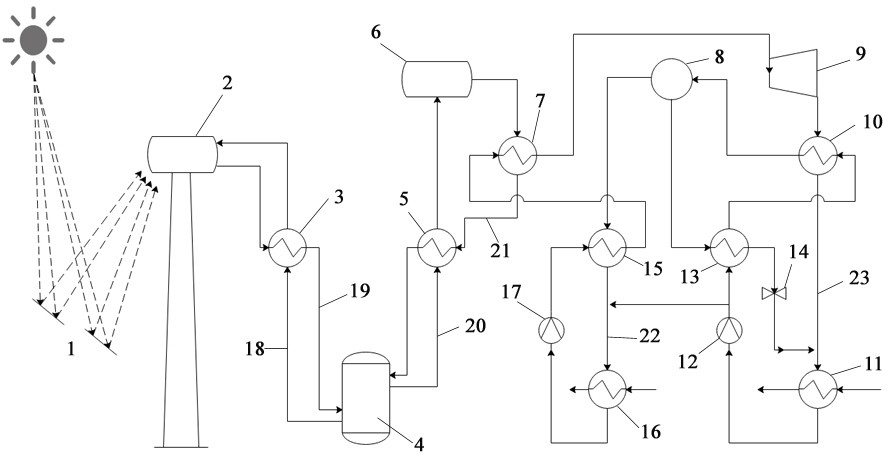

Embodiment 1

[0021] The direct solar radiation intensity is taken as 1kW / m 2 , through the amino thermochemical energy storage system, the reaction product at about 550°C is generated in the adiabatic reactor 6 and enters the third heat exchanger 7 for heat exchange. Heater 15 heats up and enters the third heat exchanger 7 to be heated and overheated to produce superheated ammonia water vapor at 510°C and pressure of 8.3MPa, which enters turbine 9 to perform work, and turbine 9 discharges exhaust gas at 0.059MPa and 224°C. The exhaust gas is cooled by the fourth heat exchanger 10, then diluted to a 45% basic solution by the 35% lean ammonia solution from the throttle valve 14, enters the fifth heat exchanger 11, and is condensed by cooling water at a temperature of 16°C The saturated liquid coming out of the fifth heat exchanger 11 is pressurized by the condensation pump 12, and part of it is heated by the sixth heat exchanger 13 and the fourth heat exchanger 10, and then enters the separa...

Embodiment 2

[0023] The direct solar radiation intensity is taken as 1kW / m 2 , through the amino thermochemical energy storage system, the reaction product at about 520°C in the adiabatic reactor 6 enters the third heat exchanger 7 for heat exchange, and the ammonia solution with a concentration of about 80% is pressurized through the feed pump 17, and the seventh heat exchanger 15 After heating up, it enters the third heat exchanger 7 to be heated and overheated to produce superheated ammonia water vapor with a temperature of 415°C and a pressure of 8.3MPa, which enters the turbine 9 to do work, and the turbine 9 discharges exhaust gas at 0.059MPa and 203°C. The exhaust gas is cooled by the fourth heat exchanger 10, then diluted to a 52% basic solution by the 40% lean ammonia solution from the throttle valve 14, and then enters the fifth heat exchanger 11 and is cooled by cooling water at a temperature of 16°C. Condensation; the saturated liquid from the fifth heat exchanger 11 is pressuriz...

Embodiment 3

[0025] The direct solar radiation intensity is taken as 1kW / m 2 , through the amino thermochemical energy storage system, the reaction product at about 575°C in the adiabatic reactor 6 enters the third heat exchanger 7 for heat exchange, and the ammonia solution with a concentration of about 50% is pressurized through the feed pump 17, and the seventh heat exchanger 15 After heating up, it enters the third heat exchanger 7 to be heated and overheated to produce superheated ammonia water vapor with a temperature of 527°C and a pressure of 8.3MPa, which enters the turbine 9 to do work, and the discharge pressure of the turbine 9 is 0.059MPa and 237°C The exhaust gas is cooled by the fourth heat exchanger 10, and then diluted to a 31% basic solution by the 22% lean ammonia solution from the throttle valve 14, and enters the fifth heat exchanger 11 to be heated at a temperature of 16°C. The cooling water condenses; the saturated liquid from the fifth heat exchanger 11 is pressuriz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com