Sealed cover press-installing device of railway truck bearing

A technology of press-fitting device and railway freight car, applied in the field of press-fitting device, can solve the problems of uneven circumferential clearance, uneven axial and radial rebound force, friction, etc., so as to ensure assembly quality and improve product qualification rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better understand the technical solution of the present invention, a detailed description will be given below through specific embodiments and in conjunction with the accompanying drawings.

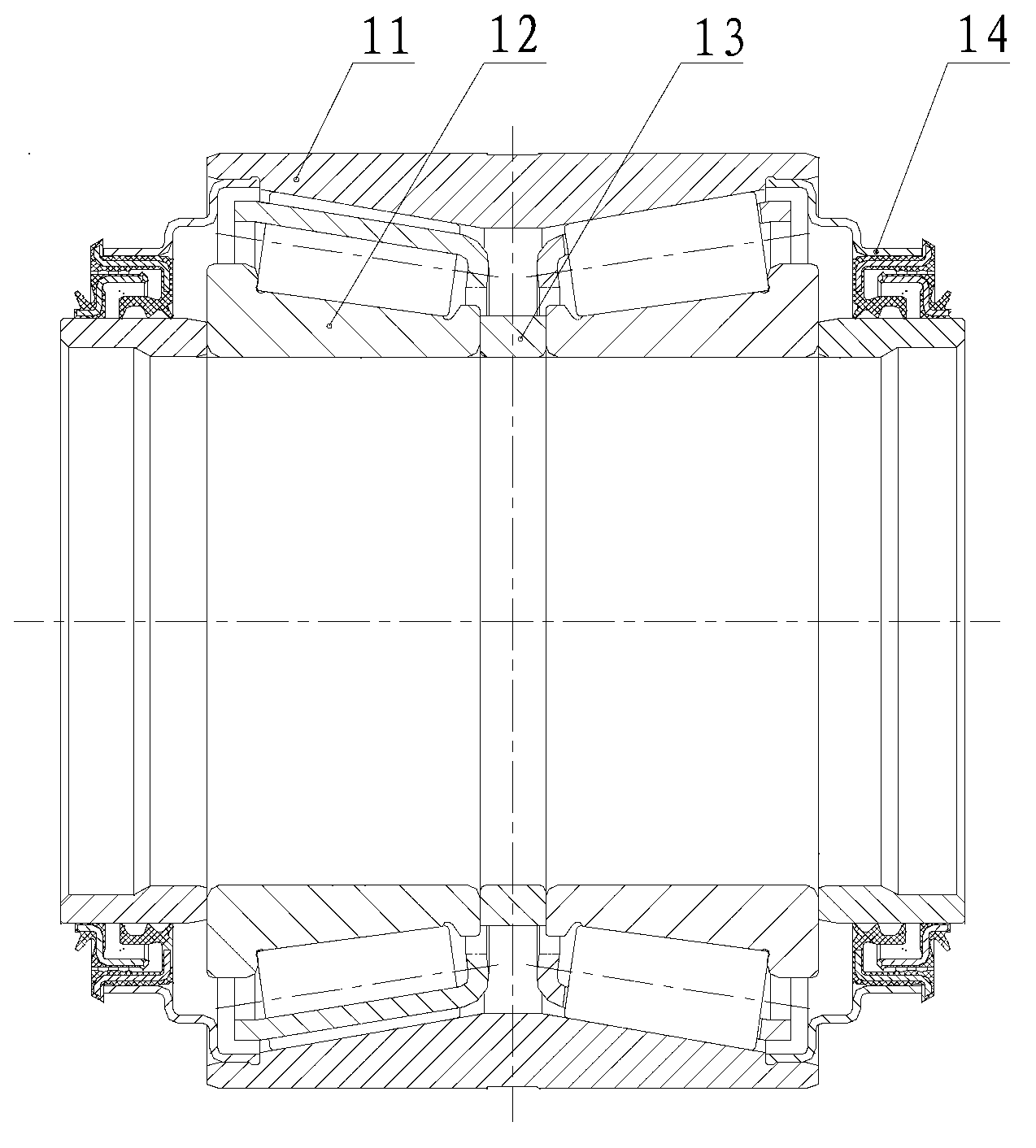

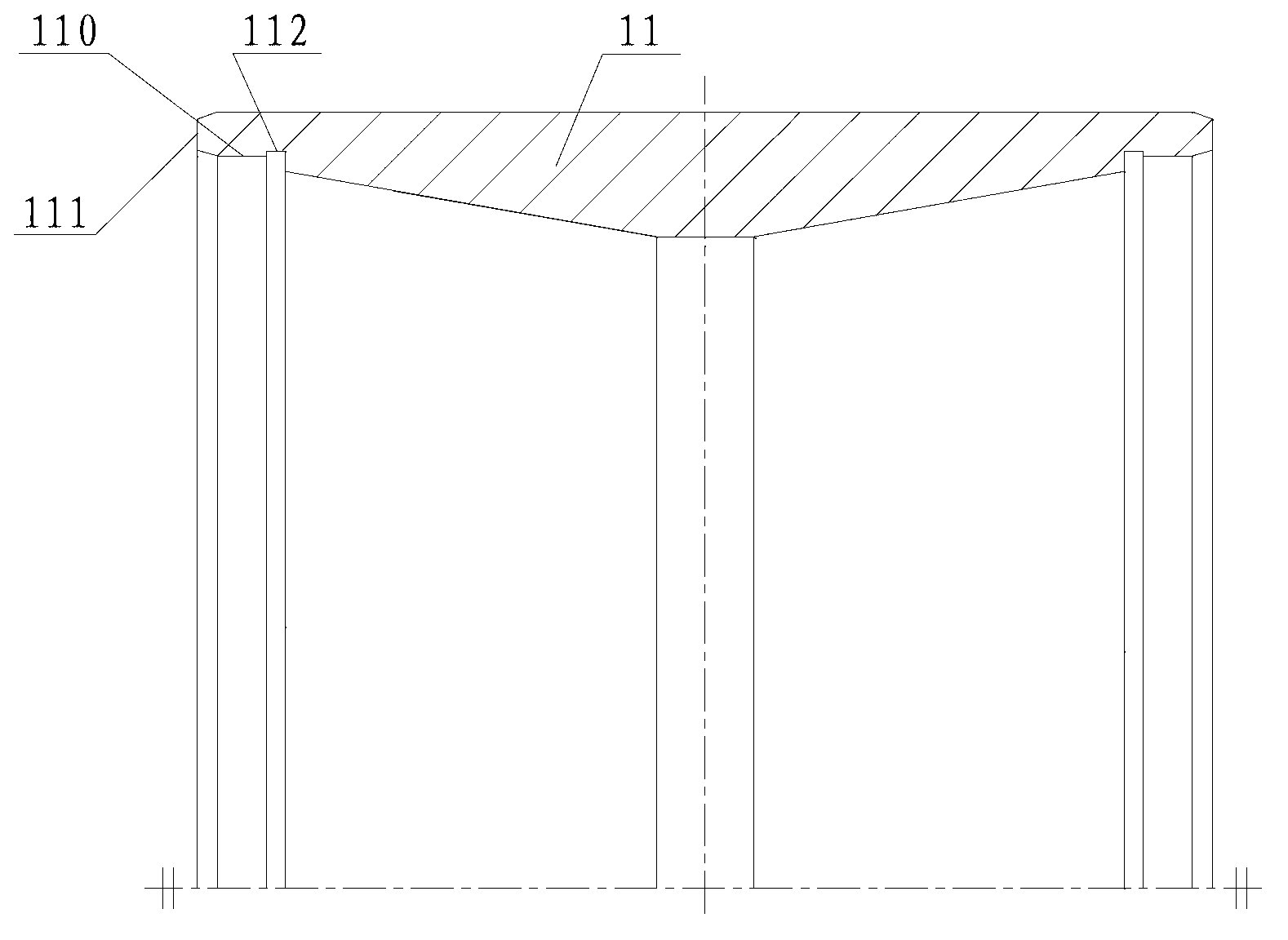

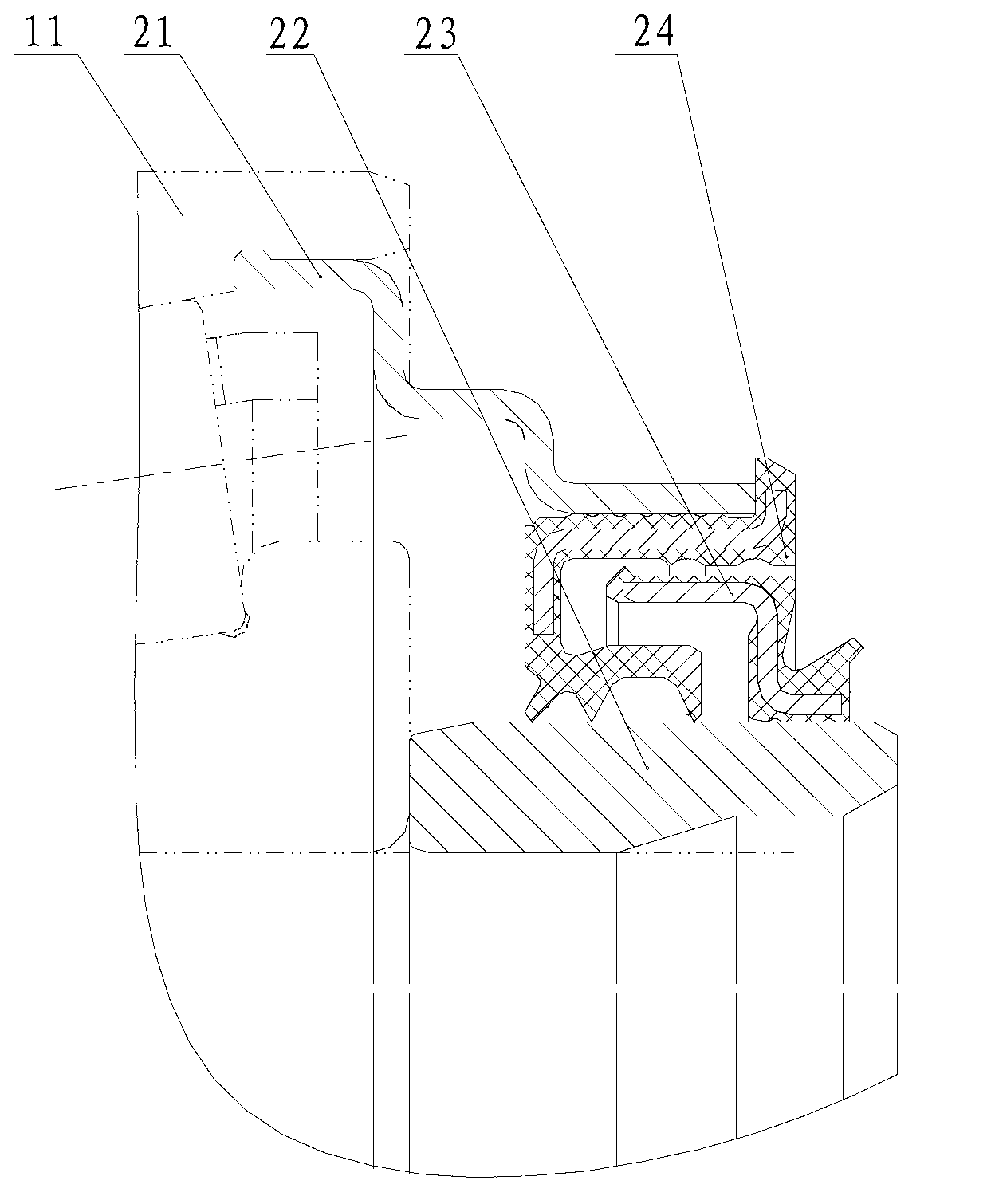

[0024] see first figure 2 and Figure 4 , the railway wagon bearing includes a bearing outer ring, a bearing inner ring and a sealing cover. The inner peripheral surface of the bearing outer ring 11 is provided with a raceway, a tooth mouth 110 and a positioning groove 112, and the outer peripheral surface of the sealing cover 21 is provided with a bearing outer ring. The positioning groove 112 on the 11 fits the boss 210.

[0025] see Figure 5 , a press-fitting device for a sealing cover of a railway freight car bearing of the present invention is a sleeve-shaped structural member whose outer peripheral surface is a cylindrical surface, and the upper and lower end faces of the press-fitting device and the outer peripheral surface are respectively separated by a cir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com