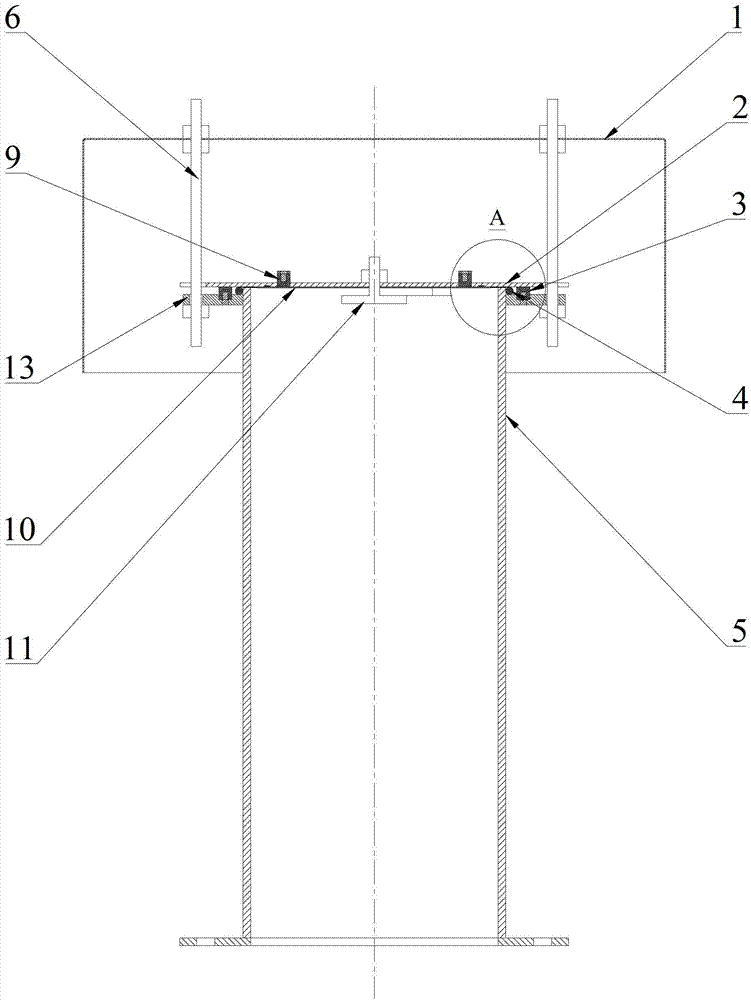

Powder tank safety valve, powder tank and stirring station

A technology for powder tanks and safety valves, applied in the field of powder tanks and mixing stations, powder tank safety valves, which can solve problems such as difficulty in taking out, safety valves that cannot be fully opened, and cannot be automatically reset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

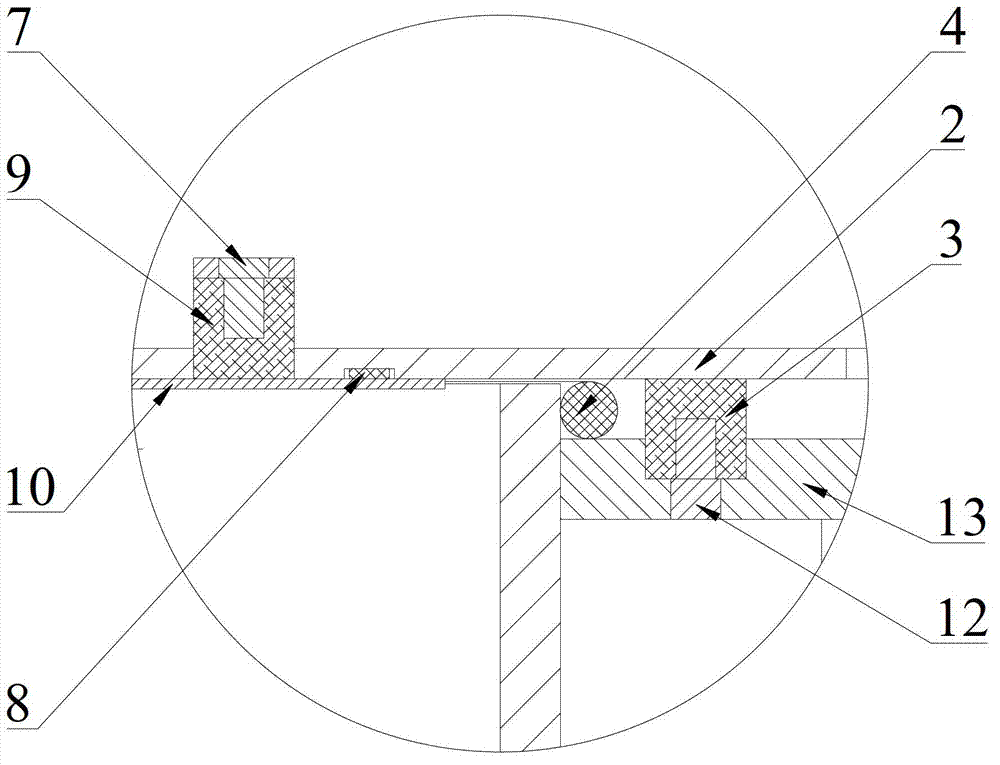

[0037] In order to break through the force-bearing form of the existing safety valve, the present invention adopts a magnetic powder tank safety valve, which includes a magnet and a valve cover capable of magnetic field attraction with the magnet, such as a valve cover made of steel material, magnetic type The opening pressure of the safety valve is equal to the sum of the magnetic force on the valve cover and the gravity of the valve cover itself (usually the safety valve is installed above the powder tank, and when the safety valve is installed below the powder tank, the opening pressure should be the difference between the magnetic force and gravity) , when the pressure in the powder tank is greater than or equal to the opening pressure, the valve cover of the safety valve opens, and the distance between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com