Tool for detecting dynamic balance of cross shaft type universal coupling

A universal coupling and cross shaft technology, applied in the field of machinery, can solve problems such as excessive material consumption, inaccurate detection, and inconvenient disassembly and assembly, and achieve the effects of less material consumption, convenient connection, and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

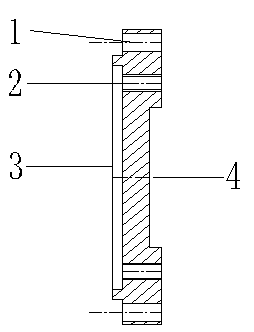

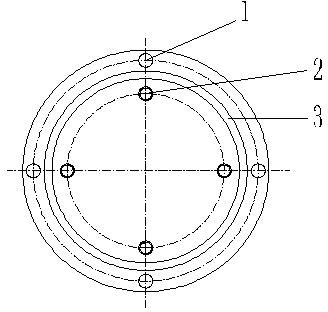

[0026] like figure 1 and 2 , the cross-shaft type universal coupling dynamic balance detection tooling of the present invention, the tooling includes a body, the body is provided with a mounting hole 1 connected with the universal coupling and a flange connection with the flange of the dynamic balancing machine The hole 2 is provided with an annular protrusion 3 on the body to match the end of the universal coupling, and an annular groove 5 is provided at the end of the universal coupling.

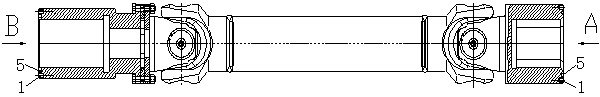

[0027] like image 3 , 4 and 5, there are four installation holes 1 in the direction A of the universal coupling, and four installation holes 1 are also provided in the direction B, and the installation holes 1 are matched with the installation holes 1 on the tooling. The A and B directions of the universal coupling are respectively provided with annular grooves 5 matching the tooling.

[0028] The installation hole 1 and the flange installation hole 2 of the tooling are threaded holes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com