Wiring harness test instrument and wiring harness test method based on wiring harness test instrument

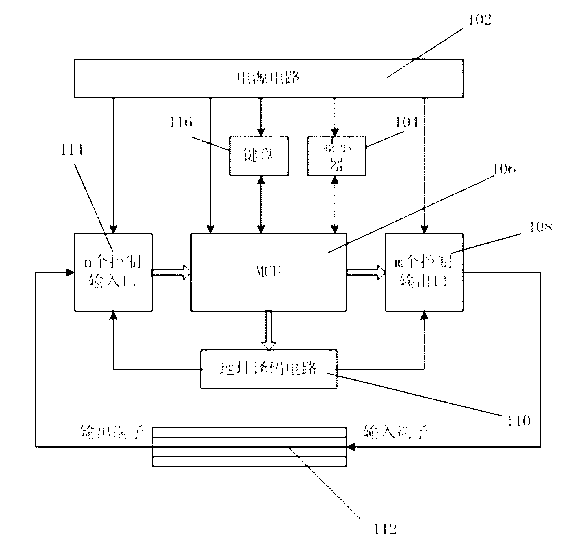

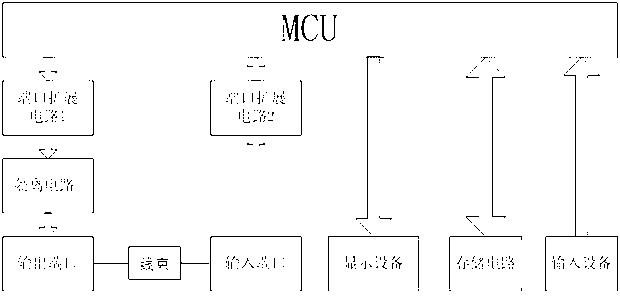

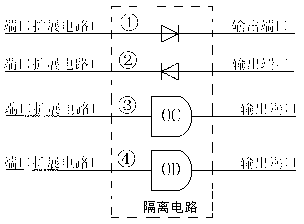

A test method and tester technology, applied in the field of wire harness testers, can solve problems such as port level interference and re-learning during circuit scanning, and achieve the effects of improving accuracy and test efficiency, improving reliability, and avoiding duplication of work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] a. When the wireless beam is connected, the constant input port level value is solidified into the memory;

[0076] b. After the wiring harness is connected, set the level status of all output ports to be opposite to that of the input port, read back and record the level data of the corresponding input port;

[0077] c. Perform logical operations on the level data recorded in steps a and b bit by bit, and record the operation results;

[0078] d. The number of effective elements and the distribution position of the effective elements in the operation result of step c are the number and position of the effective lines of the input port of the standard line.

Embodiment 2

[0080] a. When the wireless beam is connected, the constant input port level value is solidified into the memory;

[0081]b. After the wiring harness is connected, set the level status of all output ports to be opposite to that of the input port, read back and record the level data of the corresponding input port;

[0082] c. Obtain the number and position distribution of the level values that have changed at the input port, that is, the number and position of the effective lines of the standard line input port.

Embodiment 3

[0084] a. When the wireless harness is connected, if the input port levels are all low, perform logic "AND" operation on G[x][y] and H[x][y], if the input ports are all high level, Perform logic "OR" operation on G[x][y] and H[x][y] to get the array I1[x][y] (0<x≤X;0<y≤Y);

[0085] b. Do "XOR" operation with I1[x][y] and G[x][y] to get J1[x][y] (0

[0086] c. Do "XOR" operation with I1[x][y] and H[x][y] to get K1[x][y] (0

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com