Apparatus and method for focal plane change measurement

A measurement method, a technique of variation, used in the field of lithography

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

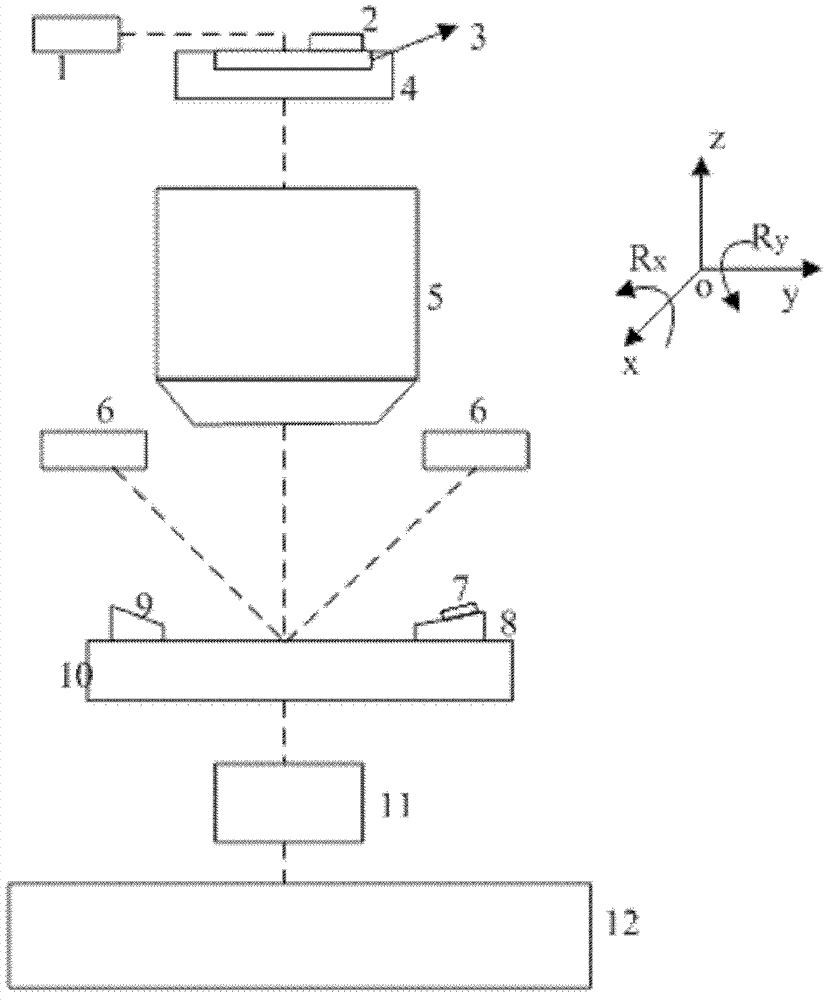

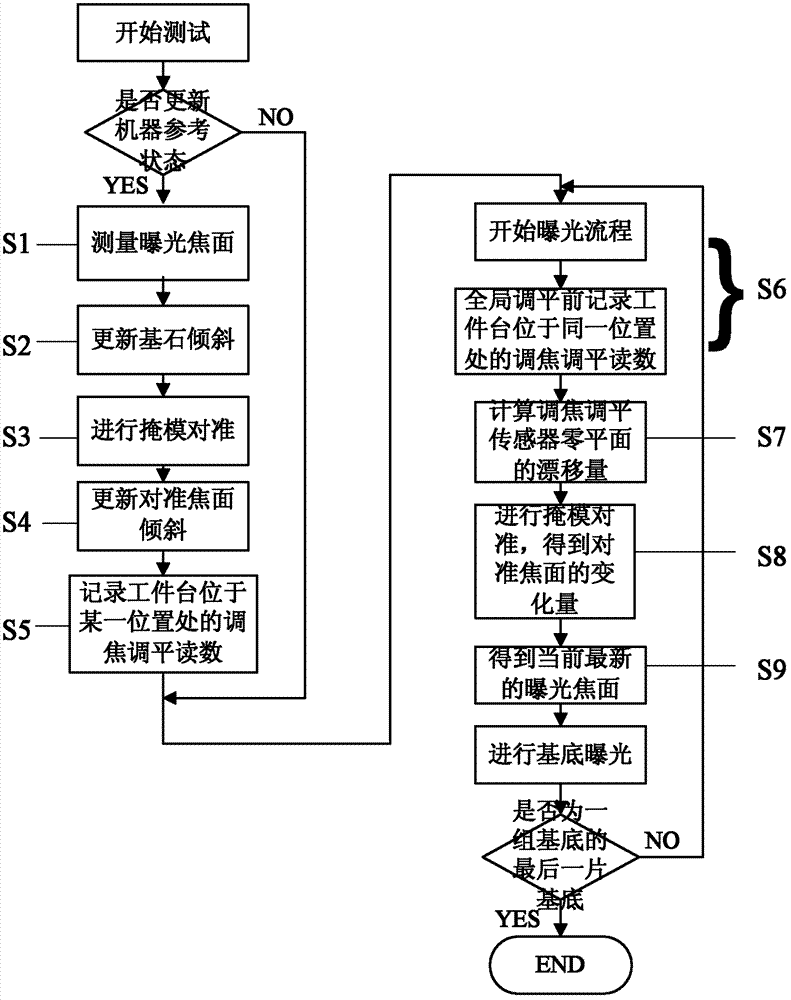

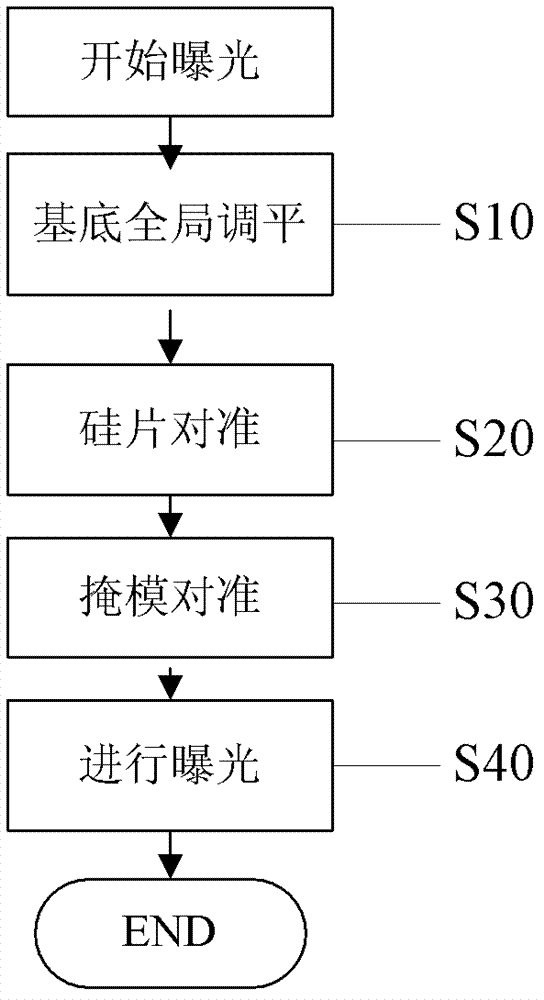

[0026] The focal plane change measuring device proposed by the present invention is as figure 1 As shown, it includes: an optical system 1, a mask mark 2, a mask 3, a mask table 4, a lens 5, a focusing and leveling sensor 6, a reference plate alignment sensor 7, a first workpiece stage reference plate 8, a Two workpiece table reference plate 9, workpiece table 10, workpiece table vertical measurement sensor 11, cornerstone 12. The functions and interrelationships of each subsystem are as follows: optical system 1 emits light source, mask mark 2 is located on mask 3 as mask 3 alignment mark, mask 3 is located on mask table 4, and mask table 4 carries the mask 3 and can move along the y and z directions, the mask mark 2 is imaged by the lens 5, and the focusing and leveling sensor 6 measures the hei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com