Key cap and manufacturing method thereof, key board with key cap, and laptop

A manufacturing method and keycap technology, which is applied to circuits, electric switches, electrical components, etc., can solve problems such as high cost pressure, affecting product user usability, and reducing user performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The core of the present invention is to optimize the design of the two main aspects of the base material of the keyboard keycap and the pattern color rendering method, so as to effectively improve the use performance of the user. In order to describe the manufacturing method of the keyboard keycap described in this solution in detail, the following will be described in detail in conjunction with the accompanying drawings in the description.

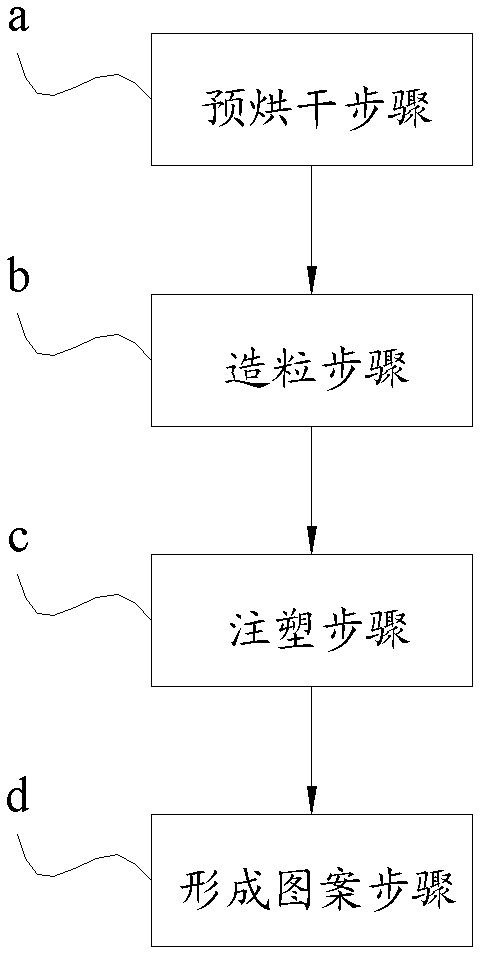

[0027] See figure 1 , which illustrates the process flow chart of the keyboard keycap described in this embodiment.

[0028] As shown in the figure, the manufacturing method of the keyboard keycap includes the following steps:

[0029] a. Pre-drying step: drying the raw polyoxymethylene particles.

[0030] In fact, the fundamental purpose of the pre-drying step is to reduce the humidity of the raw material so as to facilitate good mixing with the laser developer and improve the quality of injection molding. Therefore, the drying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com