Method for dividing workpiece

A technology for processed objects and workbenches, applied in metal processing equipment, manufacturing tools, laser welding equipment, etc., and can solve the problems of non-shrinking and insufficient shrinkage adhesive tape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

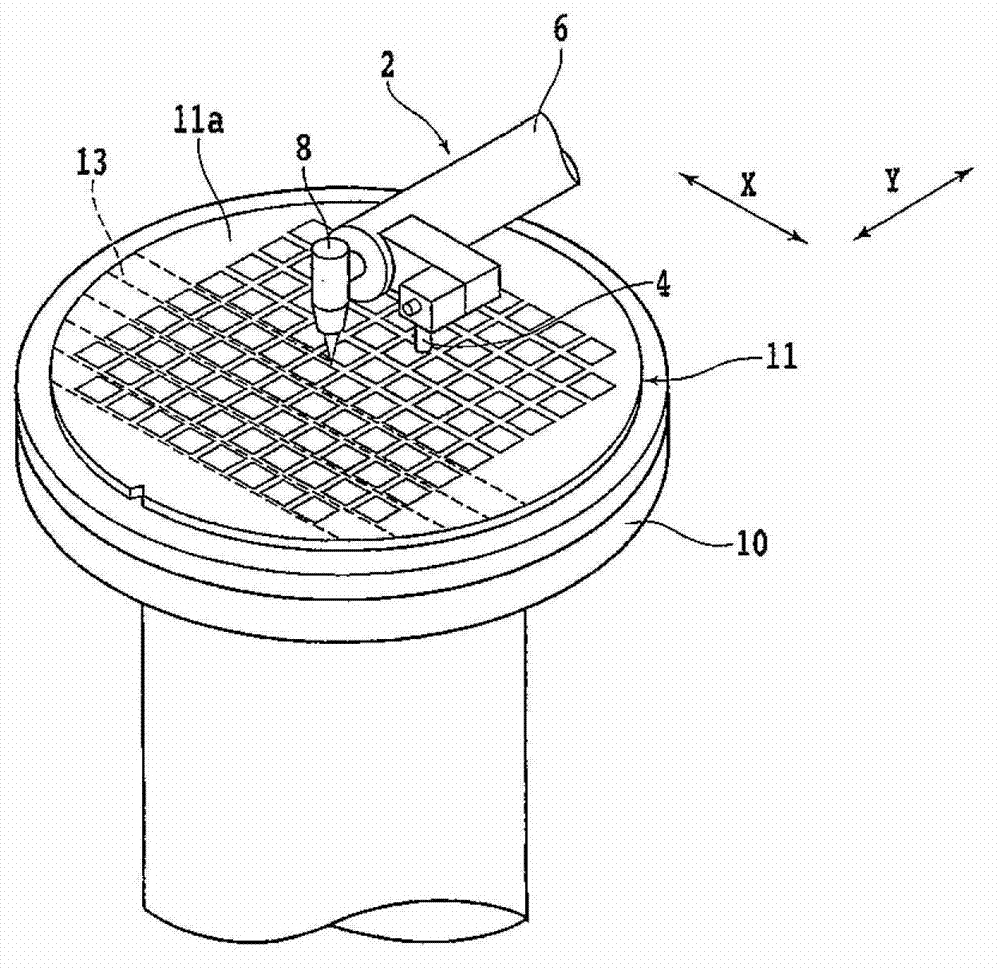

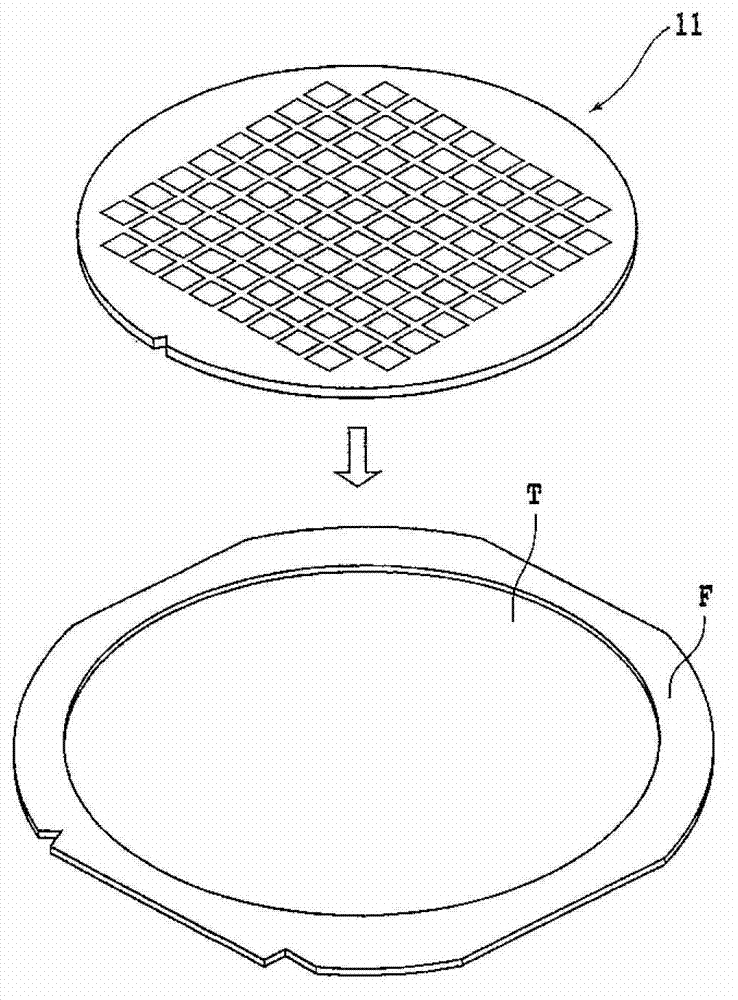

[0042] The present invention is a method of dividing a to-be-processed object in which a plurality of intersecting planned dividing lines are set along the planned dividing line. Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

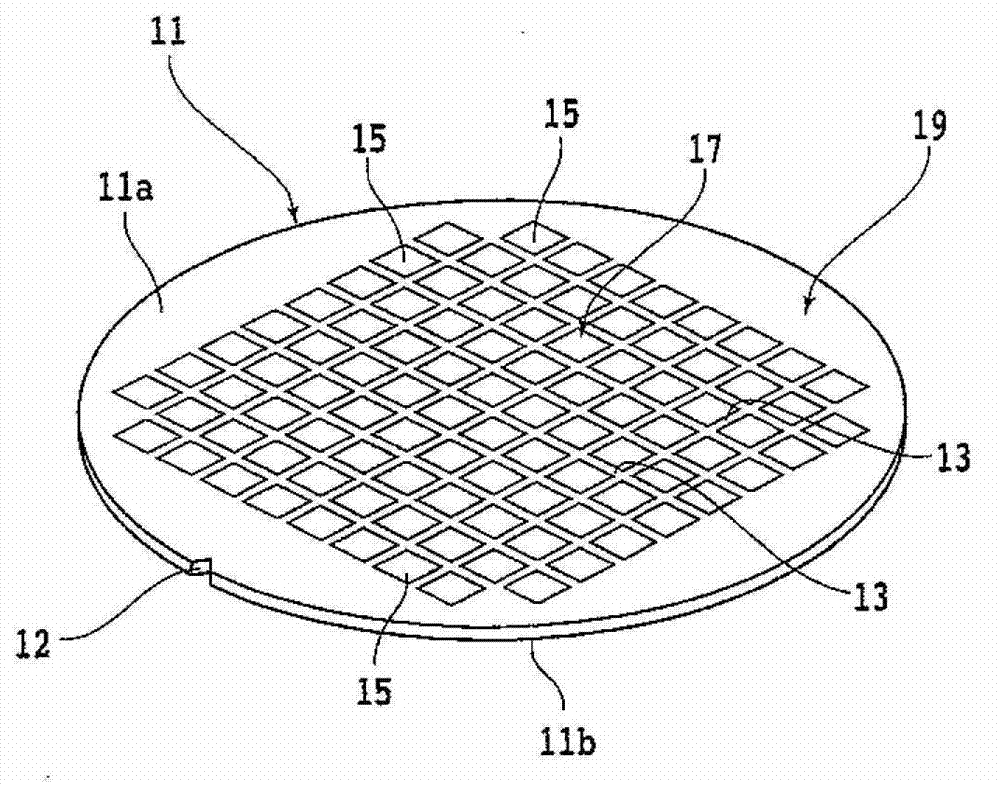

[0043] figure 1 This is a diagram showing a semiconductor wafer 11 (hereinafter, also simply referred to as “wafer 11”) as an embodiment of the workpiece. The wafer 11 is composed of, for example, a silicon wafer having a thickness of 700 μm. The wafer 11 has a plurality of intersecting planned dividing lines (spacers) 13 formed in a grid on the surface 11a, and is divided by the plurality of planned dividing lines 13 Devices 15 are respectively formed in the plurality of regions.

[0044] The wafer 11 thus configured includes a device region 17 in which the device 15 is formed, and an outer peripheral remaining region 19 surrounding the device region 17. A notch 12 is formed on the outer periph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com