LED (light emitting diode) and manufacturing method thereof

A technology of light-emitting diodes and a manufacturing method, which is applied to electrical components, electrical solid-state devices, circuits, etc., can solve the problems of high power consumption, short life, short lighting time, etc., so as to improve the efficiency of light, prolong the life, The effect of reducing production cost and power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

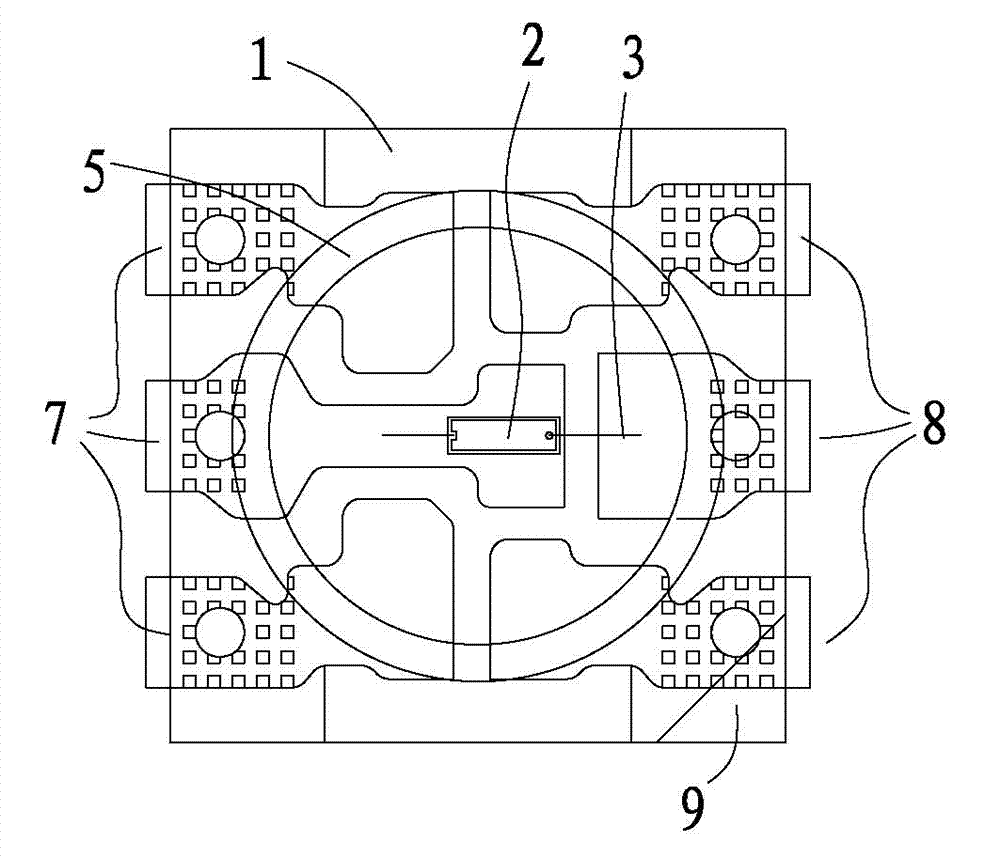

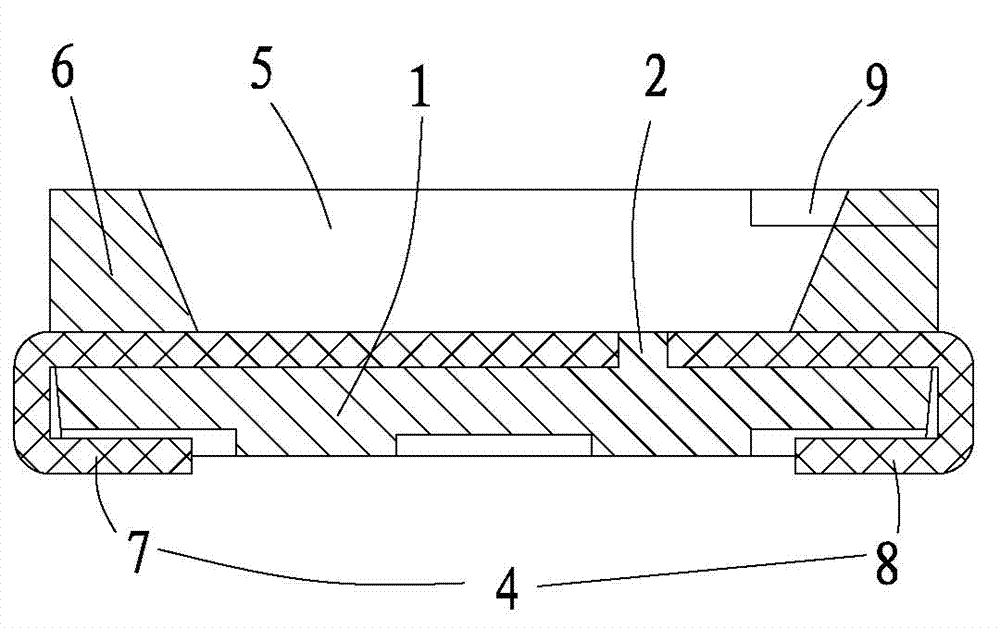

[0018] Example 1, Such as figure 1 , 2 As shown, the light-emitting diode includes a bracket 1, a light-emitting crystal 2, a gold wire 3, a power supply terminal 4, a phosphor layer 5 and a nylon layer 6, the light-emitting crystal 2 is bonded to the bracket 1, and the power supply terminal 4 passes through a gold wire 3 is electrically connected to the luminescent crystal 2, the phosphor layer 5 is coated on the luminescent crystal 2, and the nylon layer 6 is arranged around the phosphor layer 5.

[0019] Preferably, the power access terminal 4 includes a positive input terminal 7 and a negative input terminal 8, the number of the positive input terminal 7 and the negative input terminal 8 is set to three, and the three positive input terminals 7 and the three negative input terminals 8 are evenly distributed on both sides of bracket 1.

[0020] The phosphor layer 5 is arranged in a frustum-shaped structure, and the thickness of the phosphor layer 5 is 0.2-1 mm.

[0021...

Embodiment 2

[0023] Example 2 ,Such as figure 1 , 2 As shown, a method for manufacturing a light-emitting diode, the steps include: step 1, placing the light-emitting crystal 2 on the metal material in the middle of the bracket 1, bonding the light-emitting crystal 2 to the bracket 1 through an adhesive, and then baking treatment, so that the adhesive is completely cured; Step 2, electrically connect the light-emitting crystal 2 to the power supply terminal 4, and then perform the phosphor powder operation, so that the surface of the light-emitting crystal 2 is coated with a phosphor layer 5; Step 3, Then put it in a 90-degree oven and bake for 50 minutes, then transfer it to a 150-degree oven and bake for 2.5 hours, and finally get a light-emitting diode, which can be used normally after being tested and passed the test.

[0024] The phosphor point operation in the above step 2 includes the following steps: the first step is to mix the phosphor powder with a particle size of 15um and t...

Embodiment 3

[0028] Example 3, Such as figure 1 , 2 As shown, a method for manufacturing a light-emitting diode, the steps include: step 1, placing the light-emitting crystal 2 on the metal material in the middle of the bracket 1, bonding the light-emitting crystal 2 to the bracket 1 through an adhesive, and then baking treatment, so that the adhesive is completely cured; Step 2, electrically connect the light-emitting crystal 2 to the power supply terminal 4, and then perform the phosphor powder operation, so that the surface of the light-emitting crystal 2 is coated with a phosphor layer 5; Step 3, Then put it in a 90-degree oven and bake for 60 minutes, then transfer to a 150-degree oven and bake for 3 hours, and finally get a light-emitting diode, which can be used normally after being tested and passed the test.

[0029] The phosphor point operation in the above step 2 includes the following steps: the first step is to mix the phosphor powder with a particle size of 15um and the br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com