Generator rotor with radiating branch sheet blocking plates

A technology of generator rotor and manifold block plate, which is applied to synchronous generators, electric components, electrical components, etc., can solve problems such as unfavorable heat dissipation, brittleness, and generator failure, so as to increase the heat dissipation area of the rotor and reduce the Rotor temperature rise, good fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

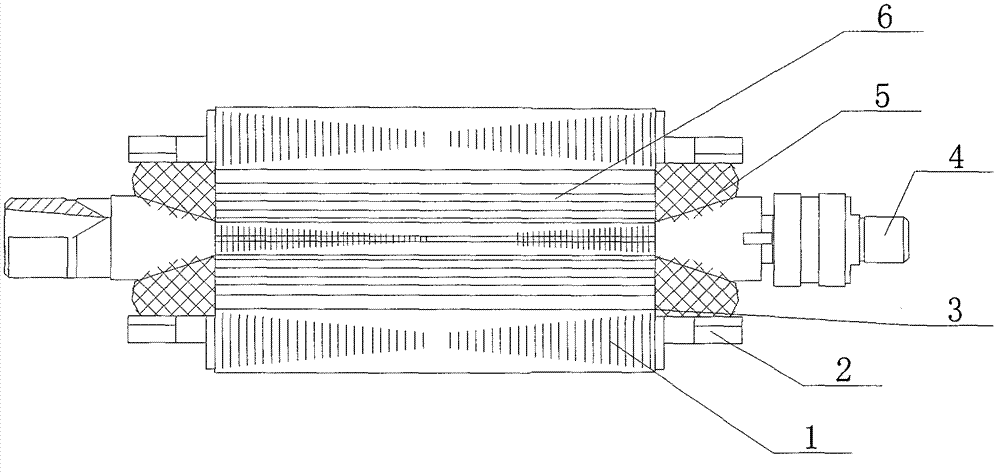

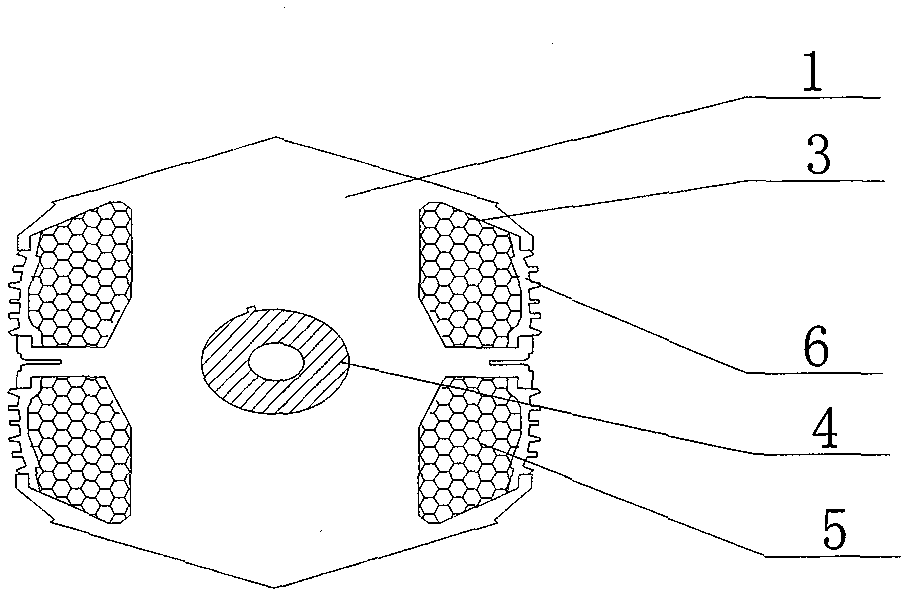

[0014] refer to Figure 1-3 , this specific embodiment adopts the following technical solutions: it includes rotor punch 1, nylon skeleton 2, insulating paper 3, rotor shaft 4, rotor enameled wire winding 5 and rotor plug plate 6, and rotor shaft 4 is laminated with multiple rotor punches. Sheet 1, the journals at both ends of the rotor shaft 4 are provided with a nylon frame 2, the inner wall of the nylon frame 2 is pasted with insulating paper 3, and the rotor enameled wire winding 5 is wound in the embedded wire groove between the nylon frame 2 and the rotor core , the rotor plug plate 6 is inserted on the outer side of the rotor enameled wire winding 5 .

[0015] The rotor plug plate 6 is made of aluminum alloy or copper alloy.

[0016] The rotor plug plate 6 is inserted into the rotor slot.

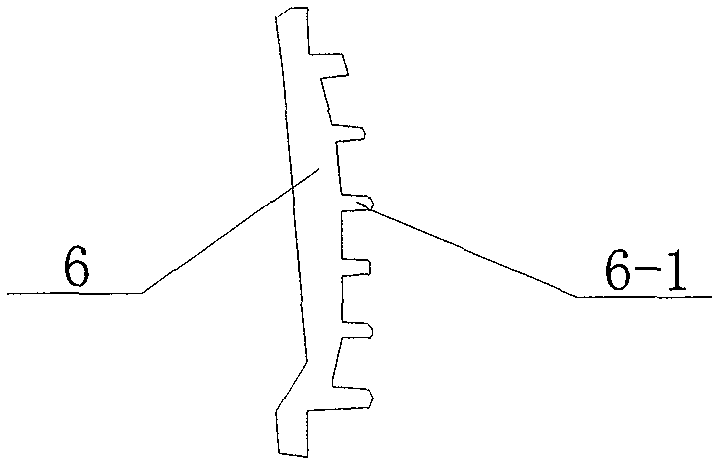

[0017] The cross-section of the rotor plug plate 6 is arc-shaped, and a plurality of cooling fins 6-1 are arranged on the outside of the arc-shaped surface.

[0018] This specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com