Laundry detergents

A laundry detergent and fabric technology, applied in the direction of detergent materials, detergent compounding agents, detergent compositions, etc., can solve the problems of inability to distinguish washing and rinsing conditions, insufficient surfactants to achieve the effect, and reduce foam. Achieve the effect of reducing the number of rinses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0210] The following examples further describe and demonstrate embodiments within the scope of the present invention. These examples are given for illustrative purposes only and are not to be construed as limitations of the invention, since many variations may be made without departing from the spirit and scope of the invention.

example 1

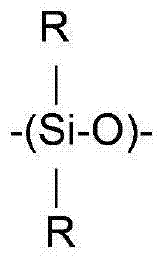

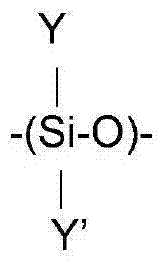

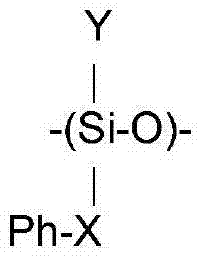

[0213] Six percent (6%) by weight of treated precipitated silica available from Evonik under the tradename Sipernat D10 was dispersed in 86.3% poly In a diorganosiloxane fluid, the polydiorganosiloxane has a degree of polymerization of 65 and contains 80 mole % methylethylsiloxane groups, 19 mole % methyl 2-phenylpropyl (derived from α- methylstyrene) siloxane groups and 1 mol% divinyl crosslinking groups. 6.7% by weight of a 60% by weight solution of an organosiloxane resin having a M / Q ratio of trimethylsiloxane units to SiO2 units in octyl stearate (70% solids) was added is 0.65 / 1. The mixture was homogenized by a high shear mixer to form foam control agent FC1.

[0214] Fourteen (14) parts of the above foam control agent FC1 were mechanically mixed with 9 parts of glyceryl tribehenate supplied by Oleon. FC1 and molten glyceryl tribehenate were mixed at 70°C. Glyceryl monobehenate is miscible with the polydiorganosiloxane fluid, and the mixture has a melting point of 65...

example 2

[0217] Another similar suds control agent, FC2, was prepared essentially the same as FC1, except that the polydiorganosiloxane fluid was different from that in FC1. In FC2, instead of using an 86.3% polyorganosiloxane fluid, which has a degree of polymerization of 65 and contains 80 mole % methyldodecylsiloxane, 20 mole % methyl 2-phenylpropyl (derived from [ α]-methylstyrene) siloxane groups.

[0218] Thirteen and a half (13.5) parts of the above suds control agent FC2 were mechanically mixed with 9 parts of glyceryl tristearate supplied by Oleon. FC2 and molten glyceryl tristearate were mixed at 70°C. Glyceryl tristearate is miscible with polydiorganosiloxane fluid and the mixture has a melting point of 62°C. The mixture of glyceryl tristearate and FC2, and 4 parts of a 1% aqueous solution of Polyquaternium-10JR30M cationic polymer were slowly poured into a mixer into which 73 parts of sodium sulfate powder had been stirred. The mixture was continuously stirred until a gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com