Method for driving plasma display panel, and plasma display apparatus

A technology for display panels and driving methods, applied to static indicators, instruments, etc., can solve problems such as increased impedance and unstable writing action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

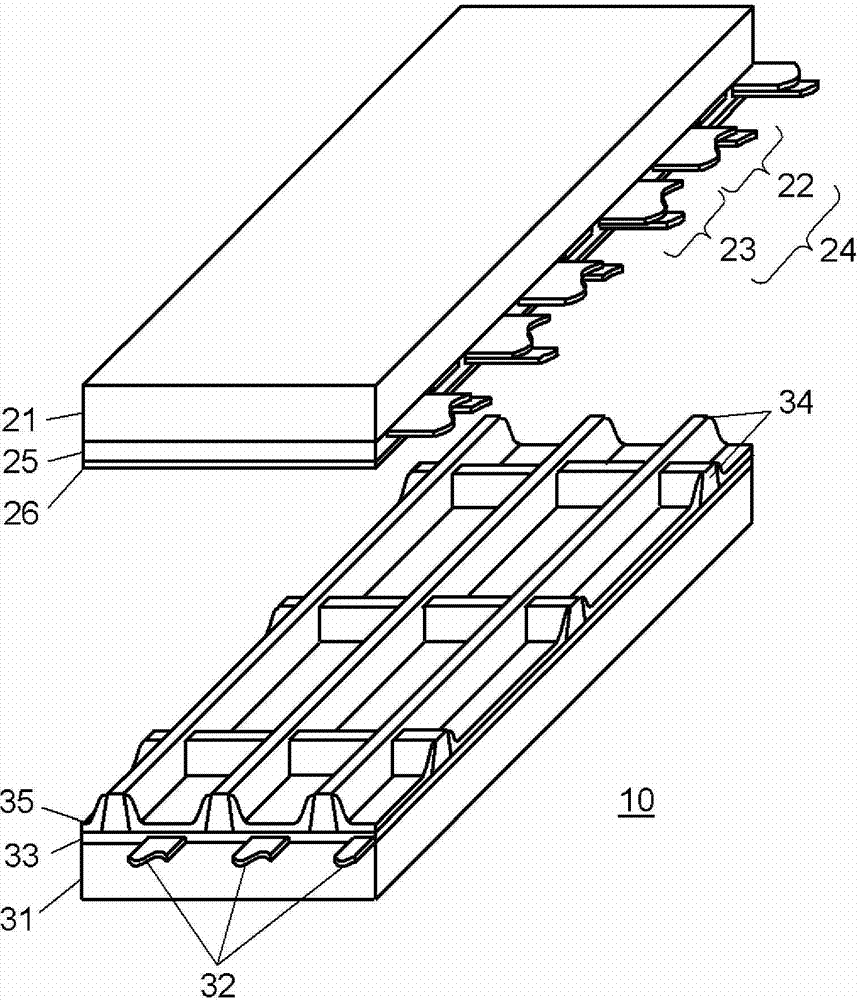

[0060] figure 1 It is an exploded perspective view showing the configuration of panel 10 used in the plasma display device according to Embodiment 1 of the present invention.

[0061] On front substrate 21 made of glass, a plurality of display electrode pairs 24 including scan electrodes 22 and sustain electrodes 23 are formed. Furthermore, dielectric layer 25 is formed to cover scan electrodes 22 and sustain electrodes 23 , and protective layer 26 is formed on dielectric layer 25 .

[0062] In order to facilitate discharge in the discharge cells, protective layer 26 is formed of a material having high electron emission performance, that is, a material mainly composed of magnesium oxide (MgO).

[0063] The protective layer 26 may consist of one layer, or may consist of multiple layers. In addition, a structure in which particles exist on a layer may also be used.

[0064] A plurality of data electrodes 32 are formed on rear substrate 31 , a dielectric layer 33 is formed to ...

Embodiment approach 2

[0245] In Embodiment 1, an example was described in which panel 10 was driven by setting the number of times of performing the initialization operation for all the cells once in one field. However, the present invention is not limited to these configurations. For example, it is also possible to apply to a configuration in which panel 10 is driven by setting the number of times of performing the initialization operation for all cells once in a plurality of fields, and in this case, the same effect as above can be obtained as well.

[0246] In the driving method in which the number of times of performing the initialization operation of all the cells is set once in a plurality of fields, compared with the configuration in which the initialization operation of all the cells is performed once in one field, it is possible to reduce the noise caused by the initialization operation of all the cells. By emitting light, the black luminance (the luminance of gradation without sustain dis...

Embodiment approach 3

[0362] In Embodiment 1 and Embodiment 2, the configuration in which the maximum voltage of the upward erasing ramp voltage L3 is set to the voltage Vr lower than the voltage Vs in all subfields has been described. However, the present invention is not limited to these configurations, and may be a configuration that generates an upward erasing ramp voltage that rises to a voltage equal to or higher than the voltage Vs.

[0363] The inventors of the present application have confirmed that, in the last subfield of one field, by applying an up-ramp waveform voltage rising to a voltage Vs or higher to scan electrodes SC1 - SCn instead of up-erase ramp voltage L3 , more stable A write action is generated.

[0364] This is considered to be because, in a subfield with a large number of sustain pulses generated in the sustain period, wall charges and trigger particles generated in the sustain operation are excessive, and therefore setting the erasing operation relatively large can stab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com