Automatic ball mounter for BGAs (ball grid arrays)

A technology of planting balls and racks, applied in the direction of tin feeding devices, auxiliary devices, electrical components, etc., can solve the problems of frequent missed ball planting and complicated processes, and achieve the effects of avoiding scattering and waste, simple operation and good automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

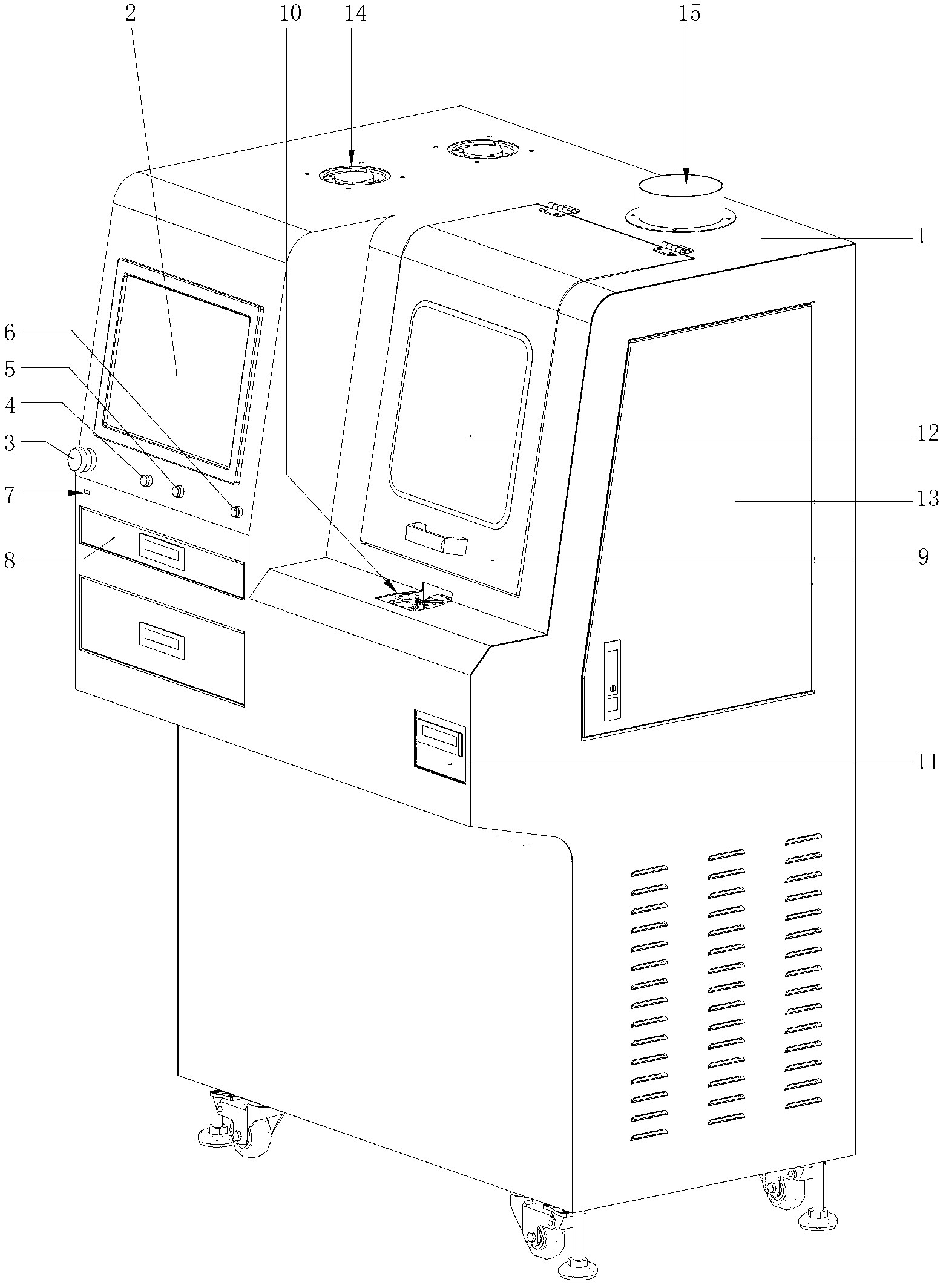

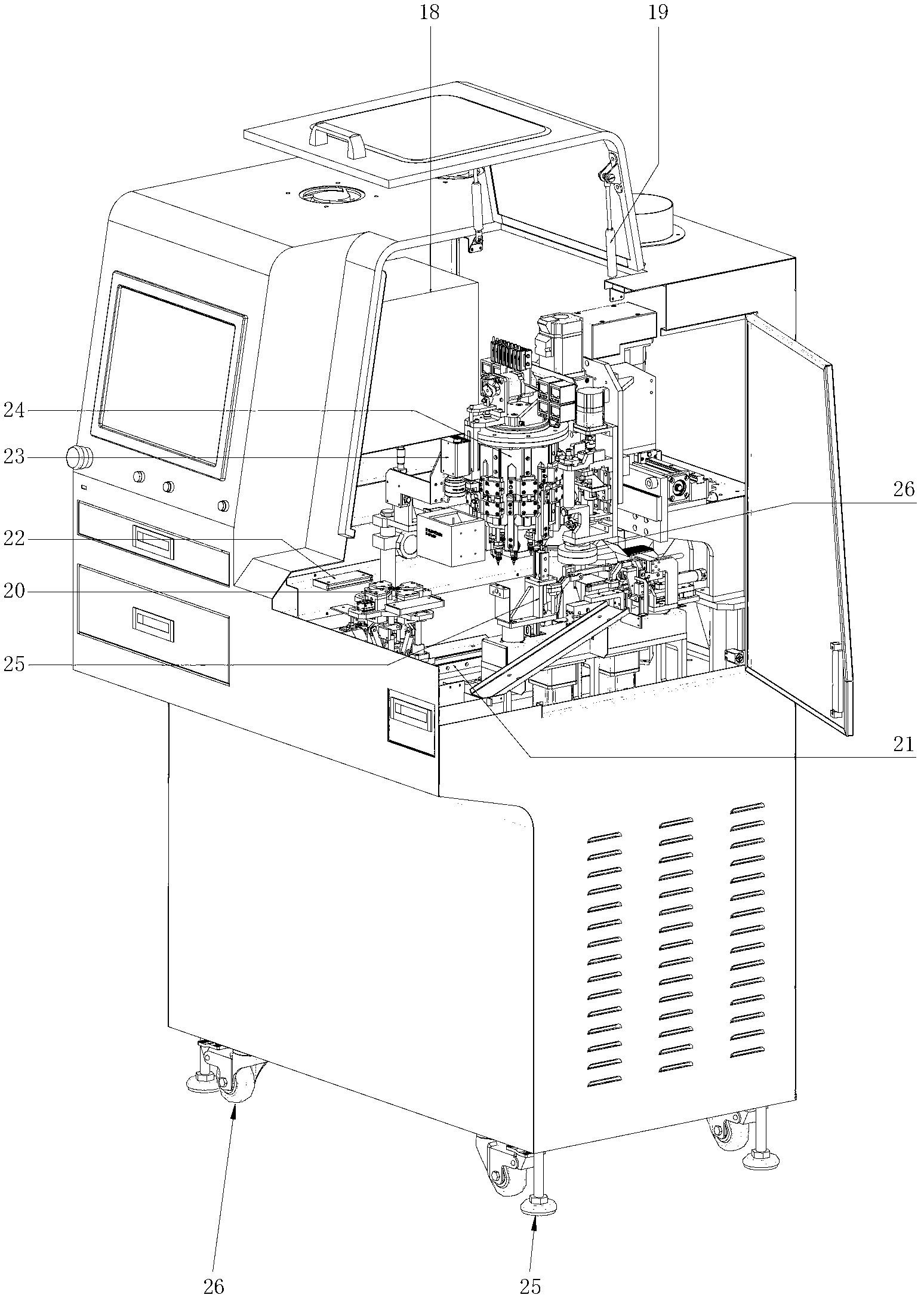

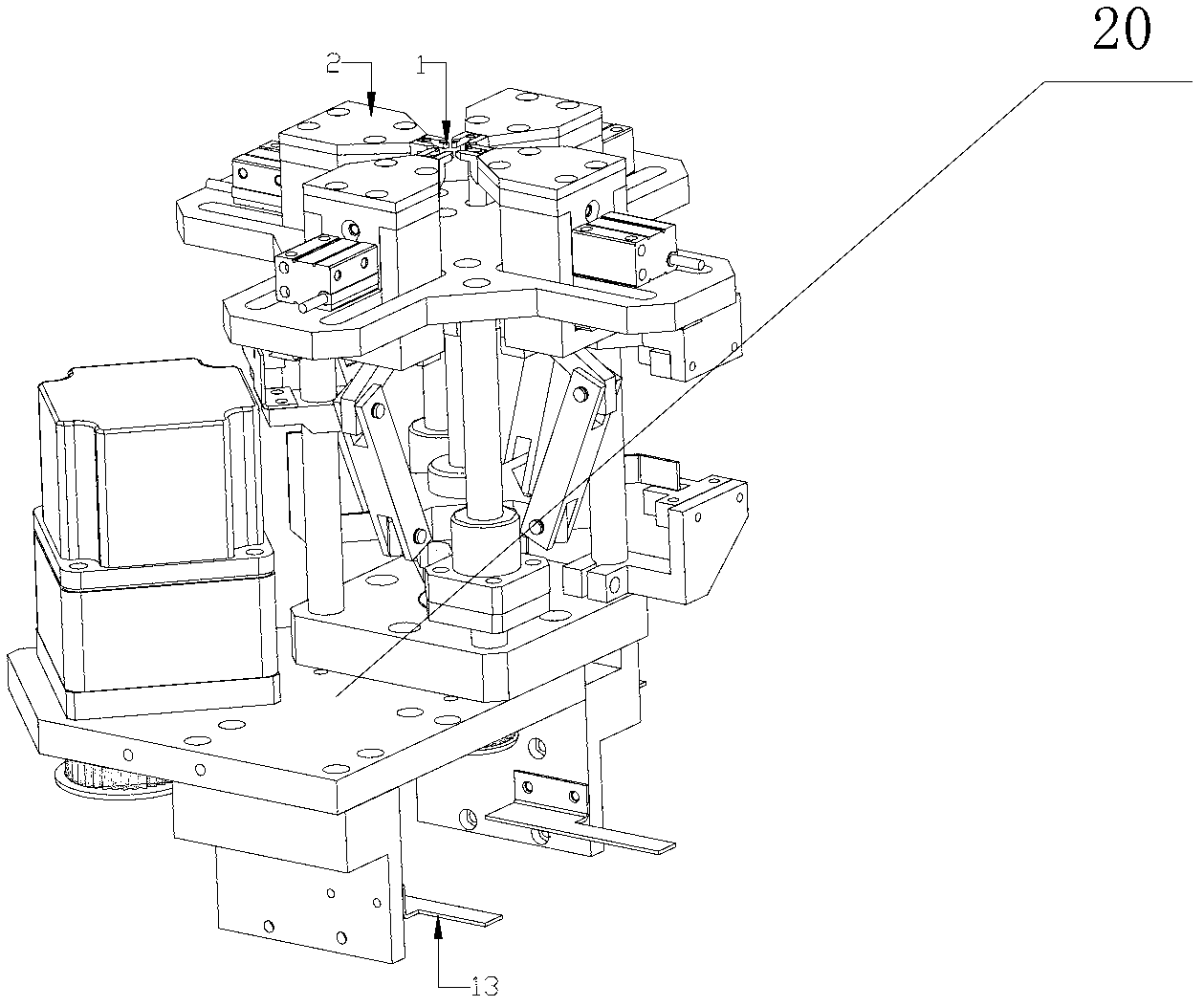

[0037] Such as Figure 1-16 As shown, a BGA automatic ball planting machine described in the embodiment of the present invention includes a frame 1, and the front end of the frame 1 is provided with an industrial computer display screen 2, an emergency stop button 3, Industrial computer button 4, start button 5, pause button 6, USB interface 7 and keyboard box 8, wherein emergency stop button 3, industrial computer button 4, start button 5 and pause button 6 are listed in a row, the frame 1 The front end is provided with a flip door 9, a material discharge window 10 and a cost storage unit 11 from top to bottom on the right side. The front side of the flip door 9 is provided with a transparent window 12. The top of the flip door 9 is provided with a nitrogen spring 19. 1 is provided with a side door 13 on the right side, a cooling system 14 and an exhaust system 15 are provided at the top of the frame 1, foot cups 16 are respectively provided at the four corners of the lower e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com