Dual-CCD (charge coupled device) welding visual monitoring system

A monitoring system and visual technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of increasing the difficulty of monitoring and the inability to realize electric control focusing, etc., and achieve an effect that is conducive to viewing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0016] In this embodiment: the monitoring box 1, the handle 4, the adapter ring 10, etc. can be processed with stainless steel; The switch and switch adopt a three-position switch; the shells of the large and small CCD7, the base 11 and the front panel 8 are all made of aluminum alloy;

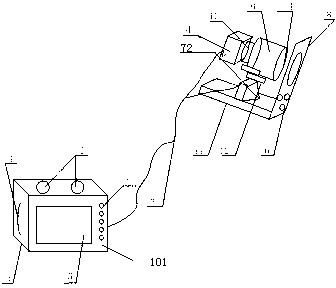

[0017] Depend on figure 1 As shown, a dual-CCD welding visual monitoring system is mainly composed of a monitoring box 1, a monitor 5, an LED lamp 6, a large and a small CCD 7, and an electric focusing lens 9. The monitor 5, the switch 3 and the handle 4 are all connected by bolts. Fixed in the box body 101, the electric fan 2 is directly powered by the 12V DC power supply inside the box body 101, and is fixed on the top of the monitoring box 1 with bolts, and the large and small CCD7, the power signal of the large and small CCD7 are set on the base 11 , video signal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com