Stirring-free flat bottom seed precipitation tank

A non-stirring, trough-splitting technology, applied in the field of seed troughing, can solve the problems of high manufacturing cost, unfavorable grain growth, poor stirring effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the drawings.

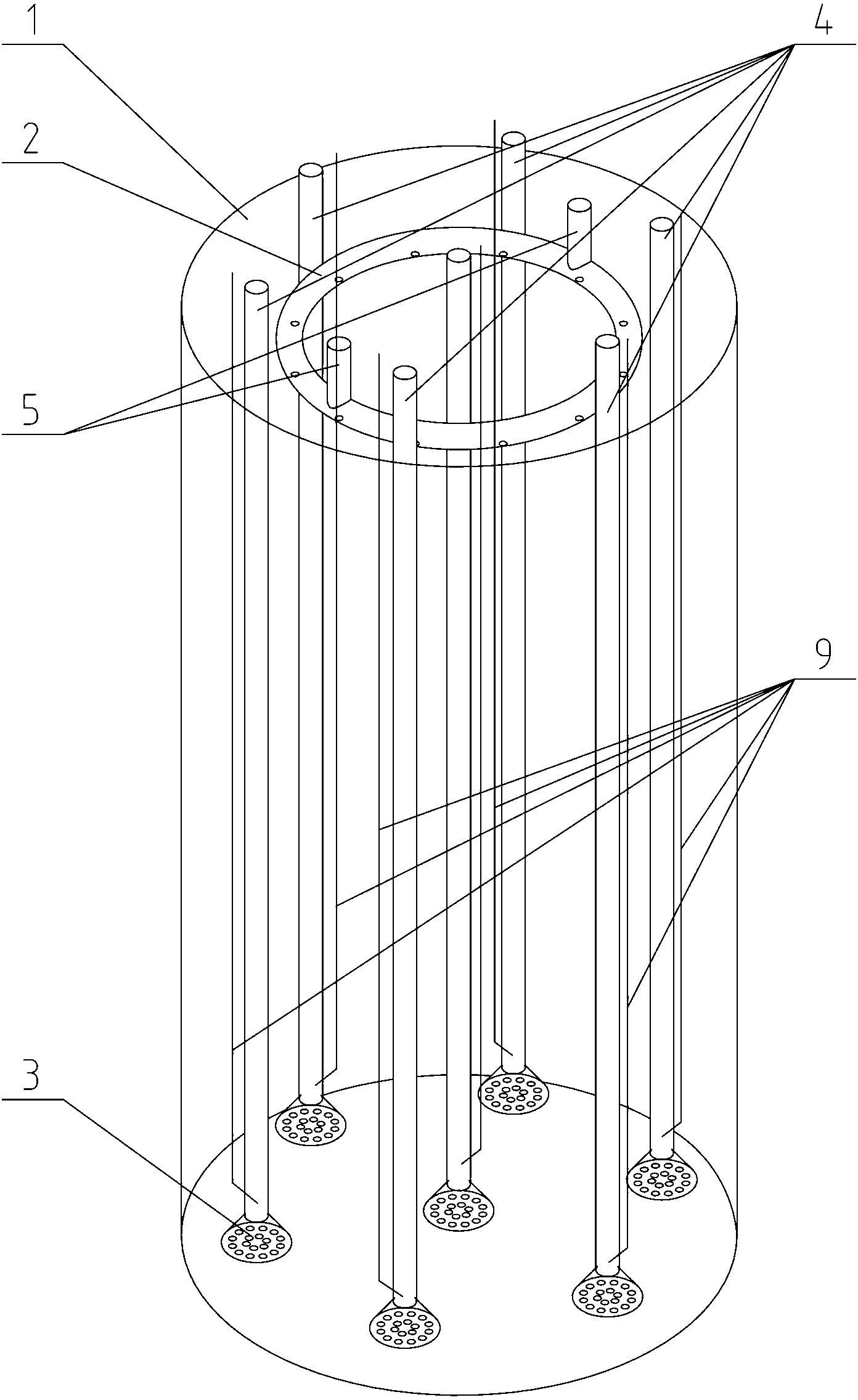

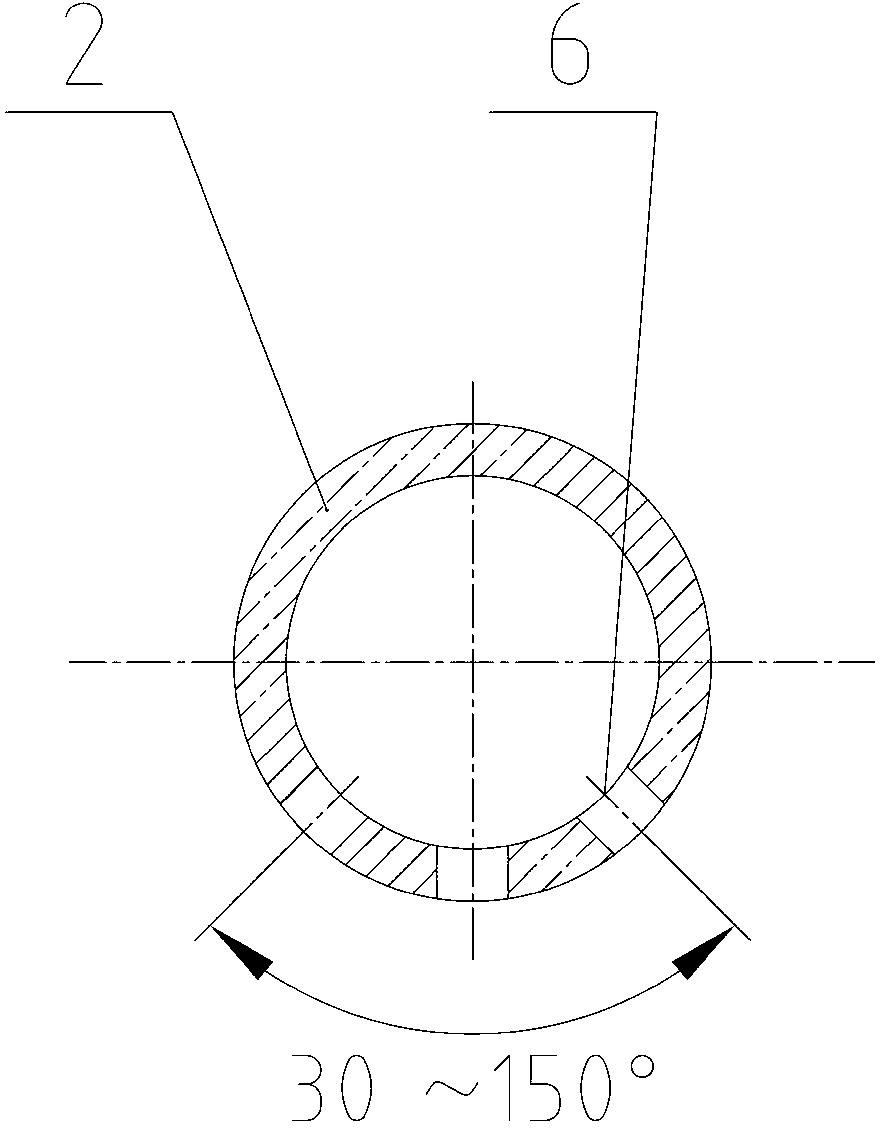

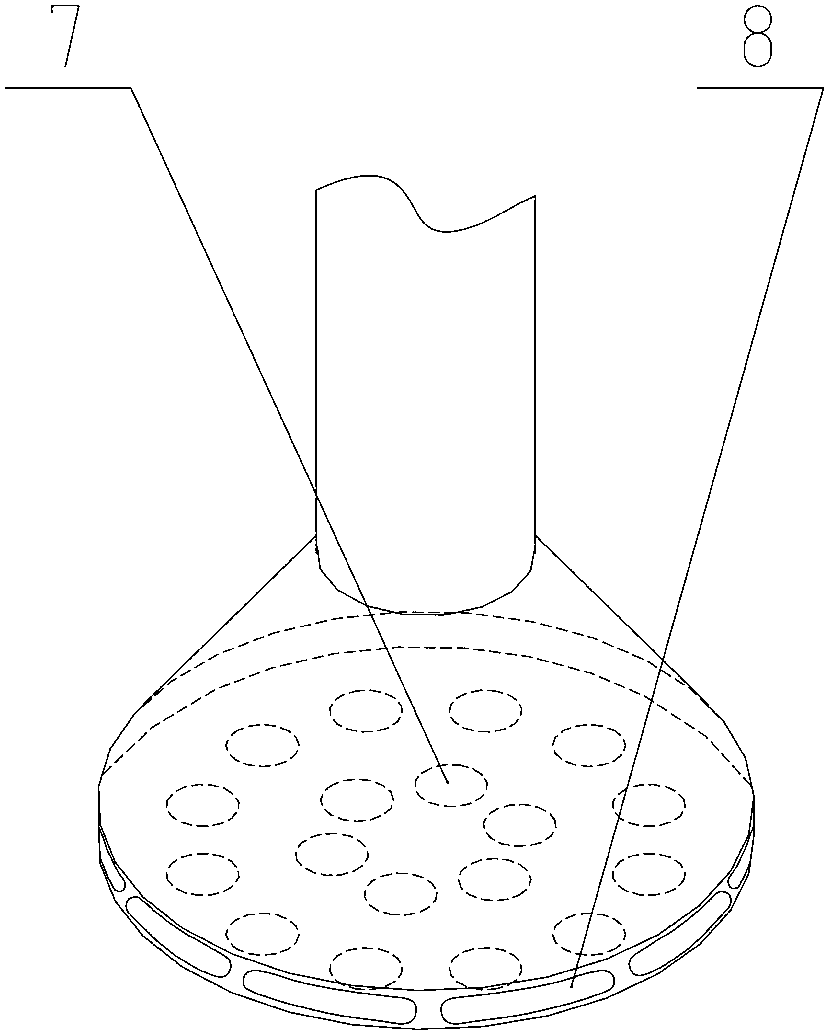

[0021] As shown in the figure, the present invention has a non-stirring flat-bottom seed dividing tank, including a seed dividing tank body 1. The seed dividing tank body 1 is a cylindrical flat-bottomed tank body, and the top of the seed dividing tank body 1 is provided with a ring-shaped distributor 2. A feed pipe 5 is provided on the circular feeder 2 and a circular hole 6 is provided at the lower end of the circular feeder 2, and a feed pipe 4 and a feed pipe 4 are provided in the seed tank body 1 The bottom of the bottom is provided with a suction pipe head 3 for the lifting pipe. The circular distributor 2 is a circular steel pipe. The diameter of the circular distributor 2 is 1 / 2 to 2 / 3 of the tank diameter. The circular distributor 2 Consists of one or more concentric pipes. When the circular distributor 2 is composed of multiple concentric pipes, the concentric pipe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap