Rubber protecting wax and preparation method thereof

A technology of rubber protective wax and microcrystalline wax, which is applied in the field of rubber additives, can solve the problems of lack of pertinence and poor protective effect, and achieve the effects of high density, extended service life, and good wax film migration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

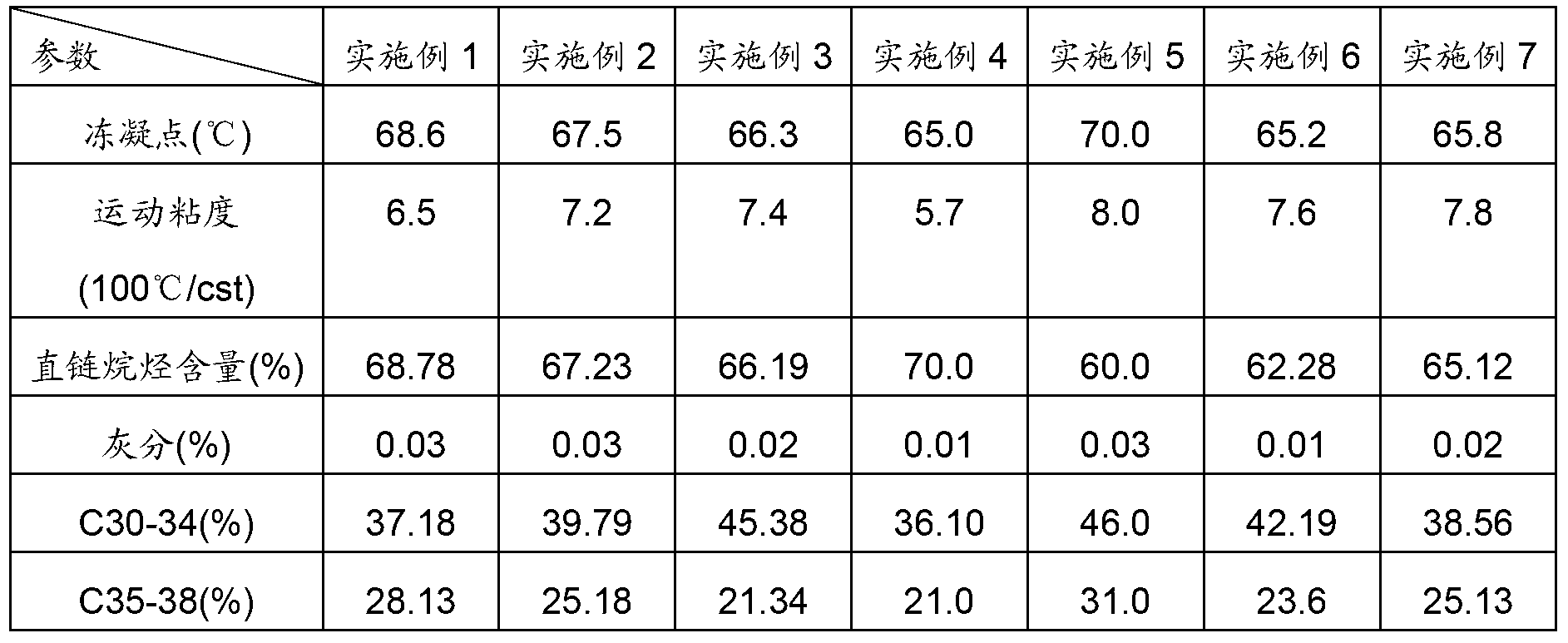

Embodiment 1

[0028] A rubber protection wax, which contains components and the weight percentage of each component: 22.0% fully refined paraffin wax, 26.0% semi-refined paraffin wax, 51.0% microcrystalline wax, and 1.0% EVA copolymer.

[0029] Wherein, the fully refined paraffin wax is 62# fully refined petroleum wax with a melting point of 63.8°C and a normal paraffin content of 65.5%; the semi-refined paraffin wax is 58# semi-refined petroleum wax with a melting point of 60.5°C and normal The alkane content is 72.8%; the microcrystalline wax is 75# microcrystalline wax with a melting point of 74.5°C and a normal alkane content of 45.7%.

[0030] Put the weighed fully refined paraffin wax and semi-refined paraffin wax into the reaction kettle, slowly raise the temperature to 135°C, after the materials are completely melted, stir at 50 rpm for 45 minutes, then add microcrystalline wax and EVA polymer, and stir for 60 minutes Finally, after all the materials are melted, they pass through a ...

Embodiment 2

[0032] A rubber protection wax, which contains components and the weight percentage of each component: 25.0% fully refined paraffin wax, 28.0% semi-refined paraffin wax, 45.5% microcrystalline wax, and 1.5% EVA copolymer.

[0033] Wherein, the fully refined paraffin wax is 62# fully refined petroleum wax with a melting point of 63.8°C and a normal paraffin content of 65.5%; the semi-refined paraffin wax is 58# semi-refined petroleum wax with a melting point of 60.5°C and normal The alkane content is 72.8%; the microcrystalline wax is 75# microcrystalline wax with a melting point of 74.5°C and a normal alkane content of 45.7%.

[0034] Put the weighed fully refined paraffin wax and semi-refined paraffin wax into the reaction kettle, slowly raise the temperature to 130°C, stir at 60 rpm for 15 minutes after all the materials are melted, add microcrystalline wax and EVA polymer, and stir for 80 minutes Finally, after all the materials are melted, they pass through a filter to fil...

Embodiment 3

[0036] A rubber protective wax, which contains components and the weight percentage of each component are: 27.0% fully refined paraffin wax, 29.0% semi-refined paraffin wax, 42.0% microcrystalline wax, and 2.0% EVA copolymer.

[0037] Wherein, the fully refined paraffin wax is 64# fully refined petroleum wax with a melting point of 65.2°C and a normal paraffin content of 63.7%; the semi-refined paraffin wax is 62# semi-refined petroleum wax with a melting point of 62.5°C and normal The alkane content is 69.1%; the microcrystalline wax is 75# microcrystalline wax with a melting point of 74.1°C and a normal alkane content of 44.6%.

[0038] Put the weighed fully refined paraffin wax and semi-refined paraffin wax into the reaction kettle, slowly raise the temperature to 140°C, stir at 70 rpm for 20 minutes after all the materials are melted, add microcrystalline wax and EVA polymer, and stir for 60 minutes Finally, after all the materials are melted, they pass through a filter to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com