Cathode protection method for heat exchanger subassembly and heat exchanger subassembly

A cathodic protection, heat exchanger technology, applied in damage protection, heat exchange equipment, lighting and heating equipment, etc., to achieve stable water flow noise, reduce water flow noise, and simple settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

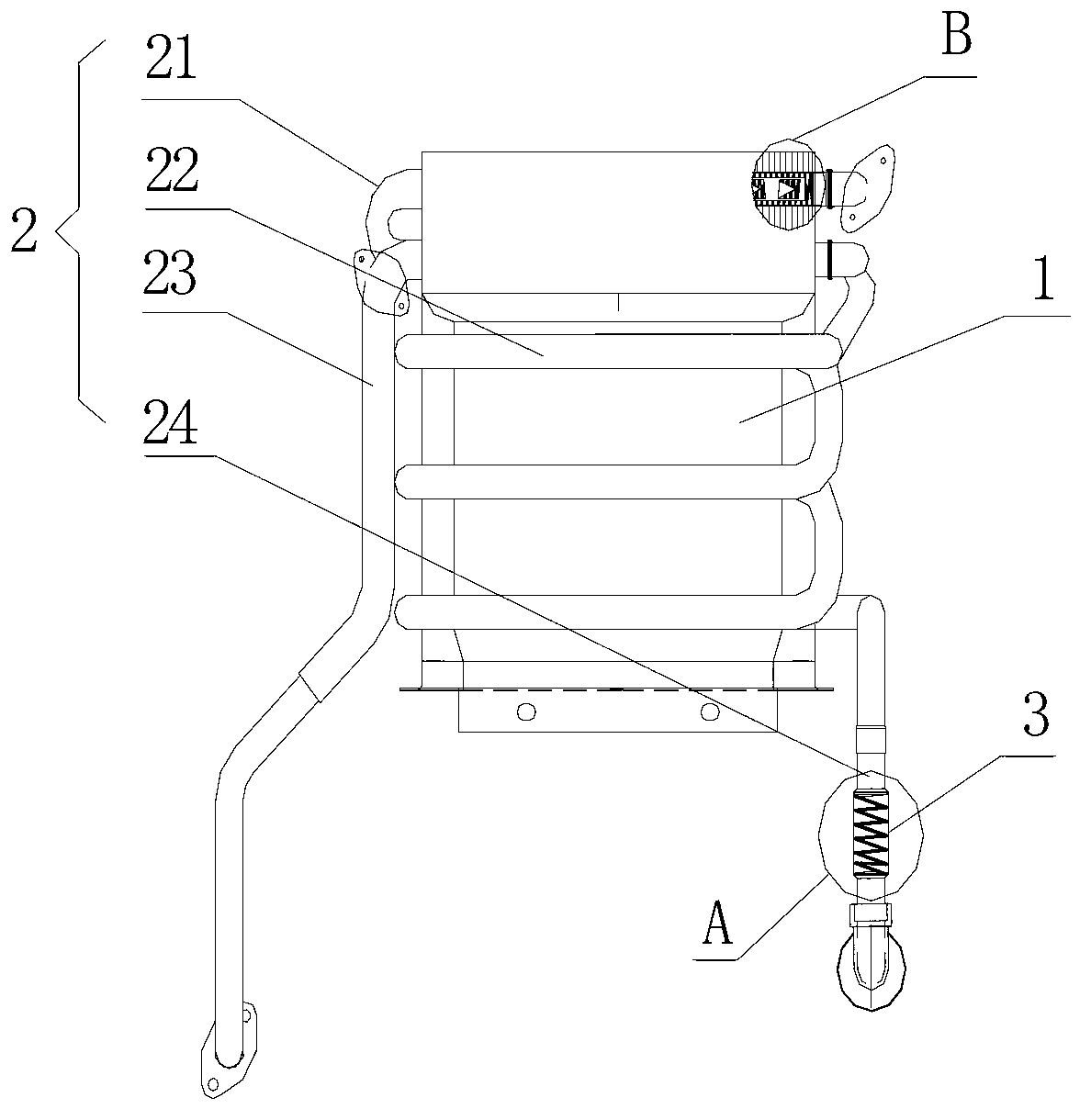

[0051] Such as figure 2 As shown, a heat exchanger part assembly based on the above-mentioned cathodic protection method, which is a main heat exchanger part assembly, includes: a heat exchanger shell 1, a heat exchange tube 2 connected to the heat exchanger shell 1, and A cathodic protection device 3 connected to the inner wall of the heat exchange tube 2 .

[0052] Wherein, the heat exchange tube 2 includes: a main heat exchange tube 21 inserted through the upper part of the heat exchanger shell 1, a coil tube 22 connected to one end of the main heat exchange tube 21 and wound on the heat exchanger shell 1, connected to The water outlet pipe 23 at one end of the main heat exchange pipe 21 and the water inlet pipe 24 connected to one end of the coil pipe 22 .

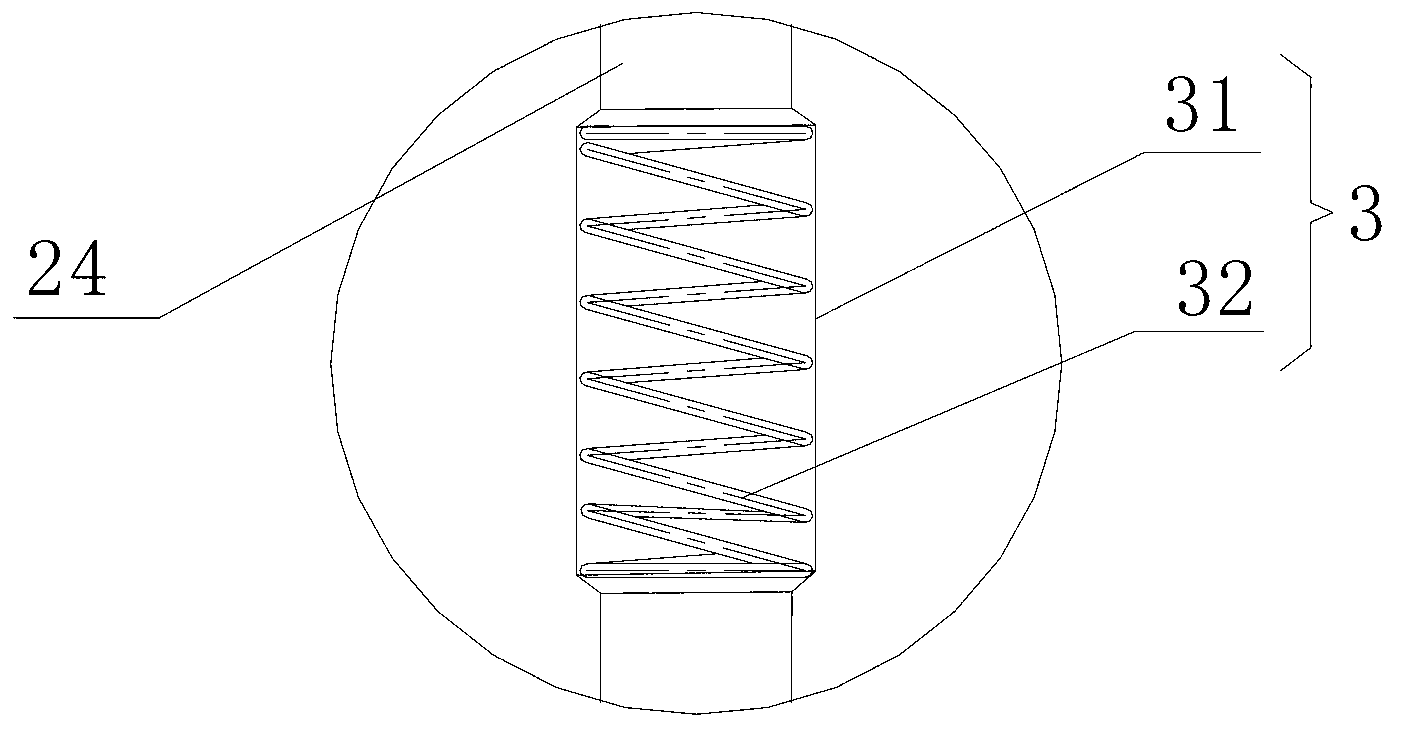

[0053] Such as image 3 As shown, the cathodic protection device 3 includes: an expansion tube 31 integrally formed with the water inlet tube 24 and an anode spring 32 arranged in the expansion tube 31 . In particu...

Embodiment 2

[0058] Such as Figure 5 As shown, a heat exchanger unit based on the above-mentioned cathodic protection method includes: a heat exchanger shell 4 with a smoke inlet 41 and a smoke exhaust port 42, and the condensation heat exchange device arranged in the heat exchanger shell 4 tube 5, and the cathodic protection device 3 connected to the inner wall of the condensing heat exchange tube 5.

[0059] The structure of a heat exchanger unit provided in this embodiment is basically the same as that of Embodiment 1, the difference is that:

[0060] 1. The main body of the heat exchanger part is a condensation heat exchange device. The smoke inlet 41 is set on the bottom side of the heat exchanger shell 1, and the smoke exhaust port 42 is set on the top of the heat exchanger shell 1. The condensing heat exchange tube 5 is arranged in the heat exchanger shell 4 in a spiral shape.

[0061] 2. The cathodic protection device 3 is an independent structure, which is screwed on the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com