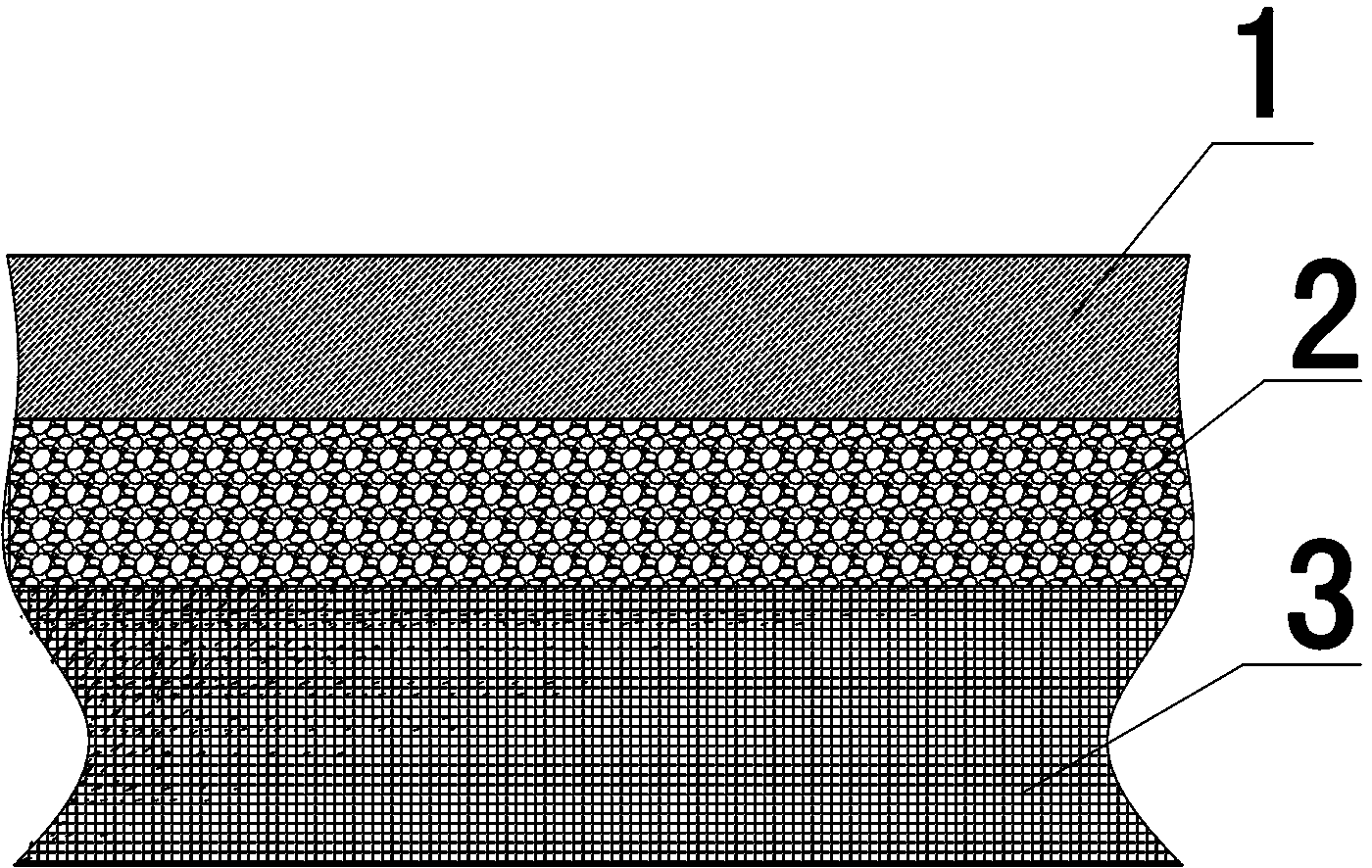

Semi-rigid pavement structure and joint type graded broken stone mixture used in semi-rigid pavement structure

A technology of pavement structure and graded gravel, applied in the direction of condensed pavement, roads, roads, etc. paved on site, can solve the problems of large permanent deformation, excessive rutting, surface network cracks, etc., to improve the road bearing capacity strength, extended service life, and improved pavement performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below through the accompanying drawings and specific examples. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0016] 1. The mixing ratio design of the coupled graded crushed stone mixture, the specific steps are:

[0017] (1) Raw material selection:

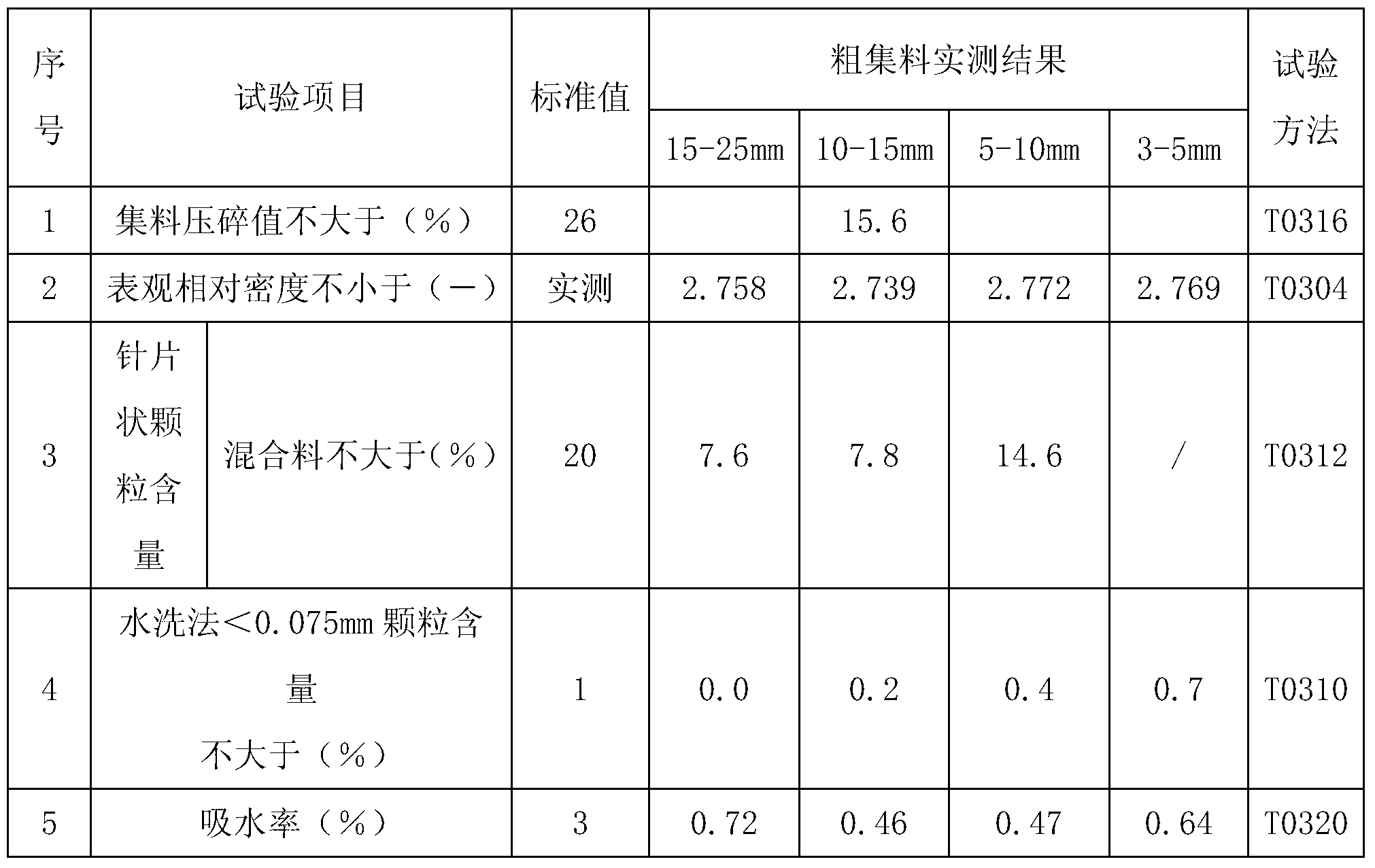

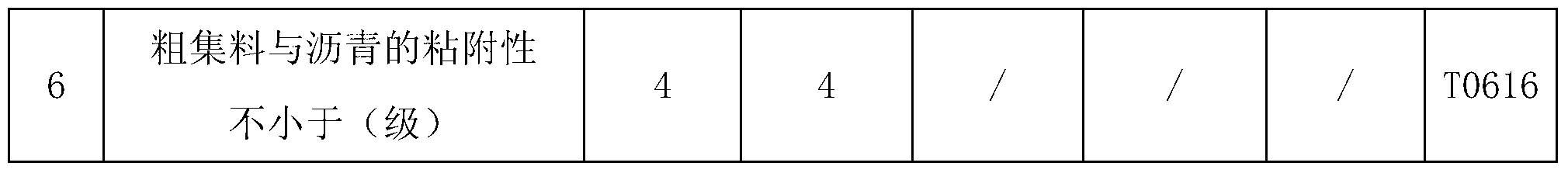

[0018] Choose crushed stone raw material: use limestone. Coarse aggregate in limestone has certain toughness, and the bonding type between limestone and asphalt is better, the workability of construction is better, it is easy to roll and form, and it is not suitable for segregation. The technical parameters of coarse aggregate are shown in Table 1, and the technical parameters of fine aggregate are shown in Table 2.

[0019] Table 1 Coarse Aggregate Technical Parameters

[0020]

[0021]

[0022] Table 2 Fine aggregate technical parameter table

[0023]

[0024] Selection o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com