Coaxially homodromous gas pressurization mechanism and gas pressurization method

A gas pressurization, coaxial and same direction technology, applied in the direction of machines/engines, liquid variable displacement machinery, mechanical equipment, etc., can solve the problems that affect the efficiency of pressure instrument calibration, low pressure, low gas pressure making efficiency, etc. , to achieve the effects of increased reliability and controllability, balanced force, and low assembly cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

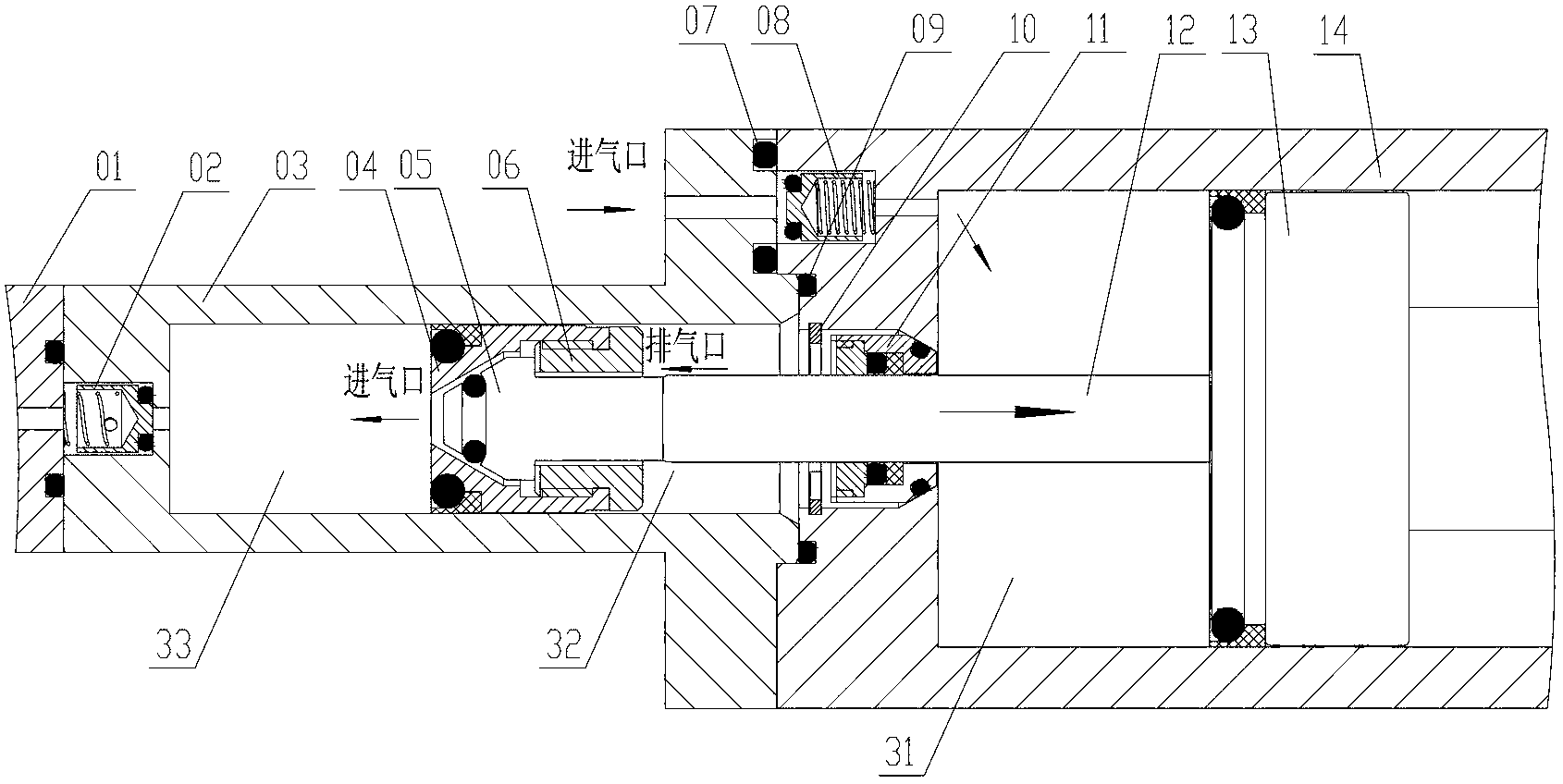

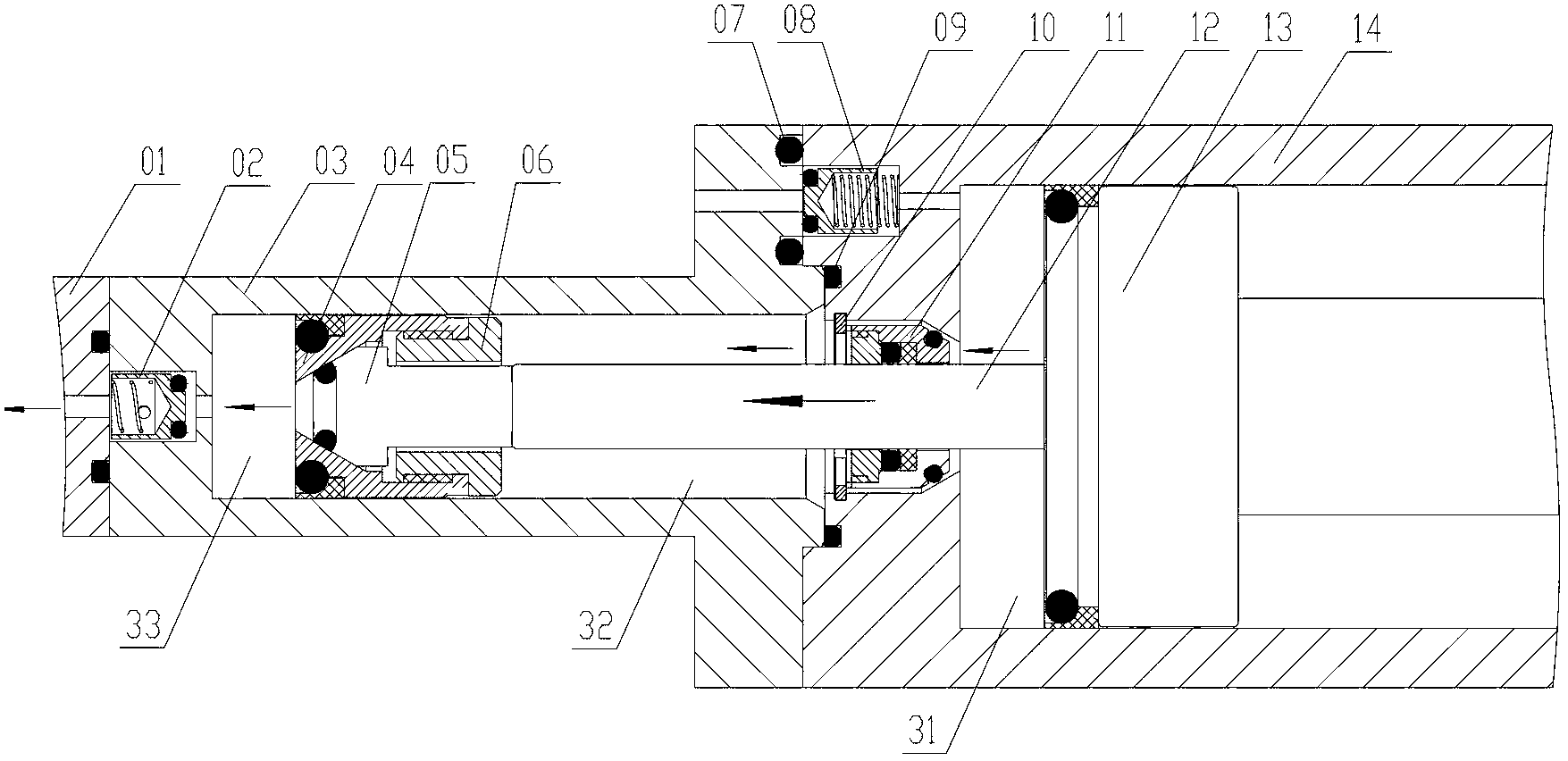

[0023] On the basis of the conventional one-stage pressure-making air pump, the present invention adds a one-stage piston and a follow-up check valve coaxially and in the same direction, and uses the change of the cavity before and after the piston movement to store and exchange gas, so that the primary compression ratio is adjusted to two stages Compression ratio, so that gas compression reaches a higher pressure range, improves gas compression efficiency, reduces the force required for compression, and adapts to modern product development concepts.

[0024] The coaxial and same-direction moving gas pressurization mechanism designed by the present invention, see figure 1 and figure 2 shown, including:

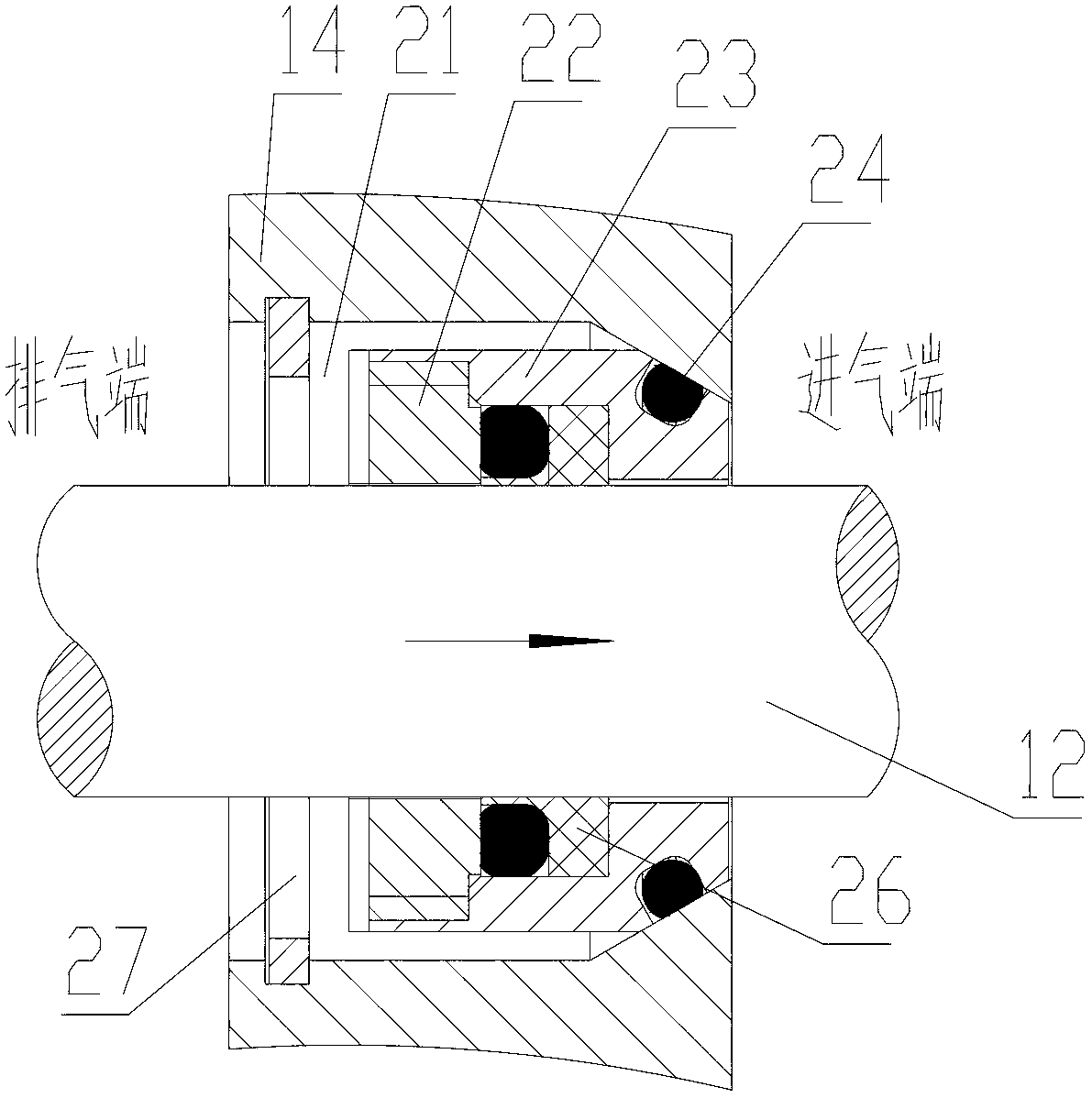

[0025] A primary cylinder 14 and a primary piston 13 and piston connecting rod 12 placed therein;

[0026] A two-stage pressurized cylinder 03 and a two-stage piston 04 placed therein; and a connecting piece 01 for connecting with a pressure instrument.

[0027] here:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com