Silencer for fuel cell car air auxiliary system

An air-assisted, fuel cell technology, used in fuel cell additives, components of pumping devices for elastic fluids, liquid fuel engines, etc., can solve problems such as inability to eliminate broadband noise, and achieve good adaptability and variable The effect of many, beautiful and compact space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

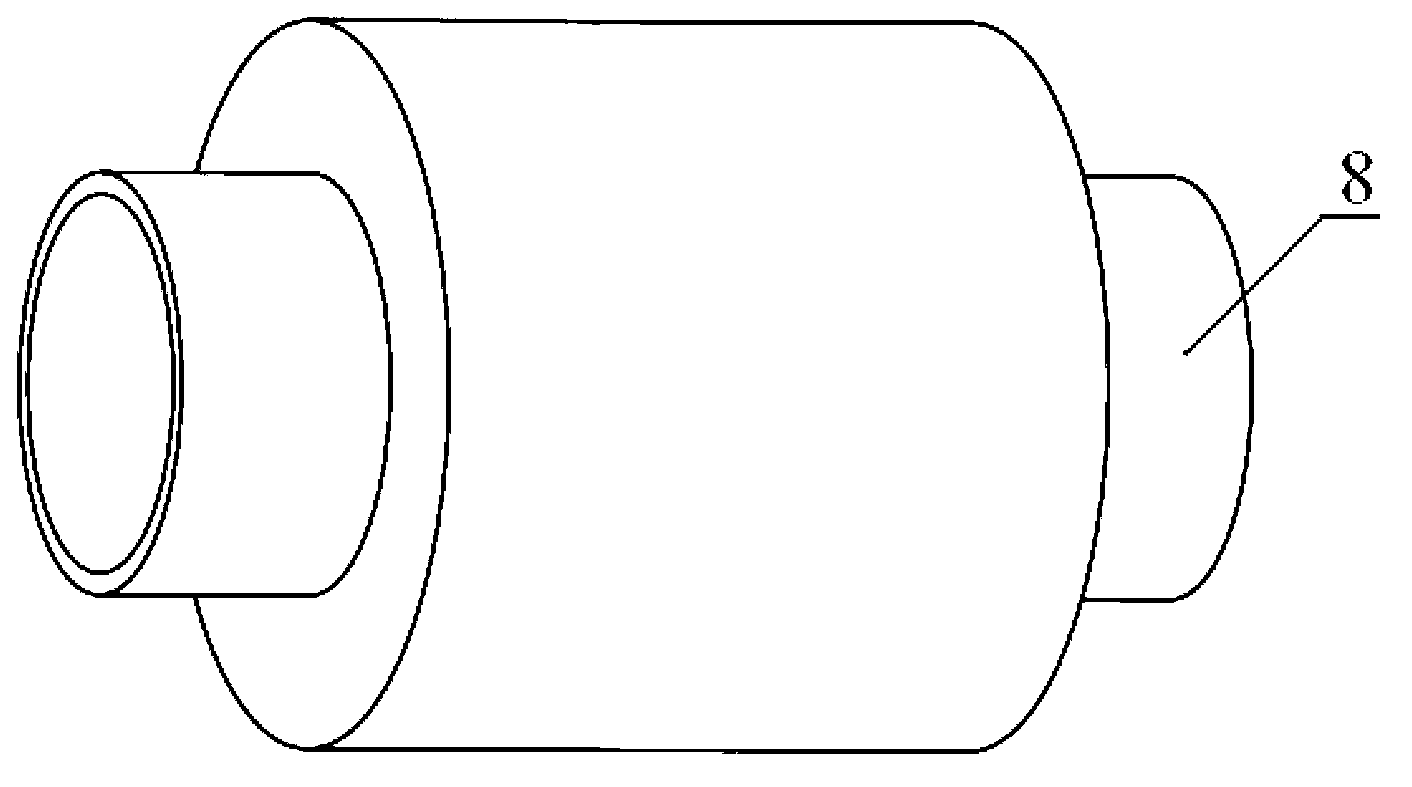

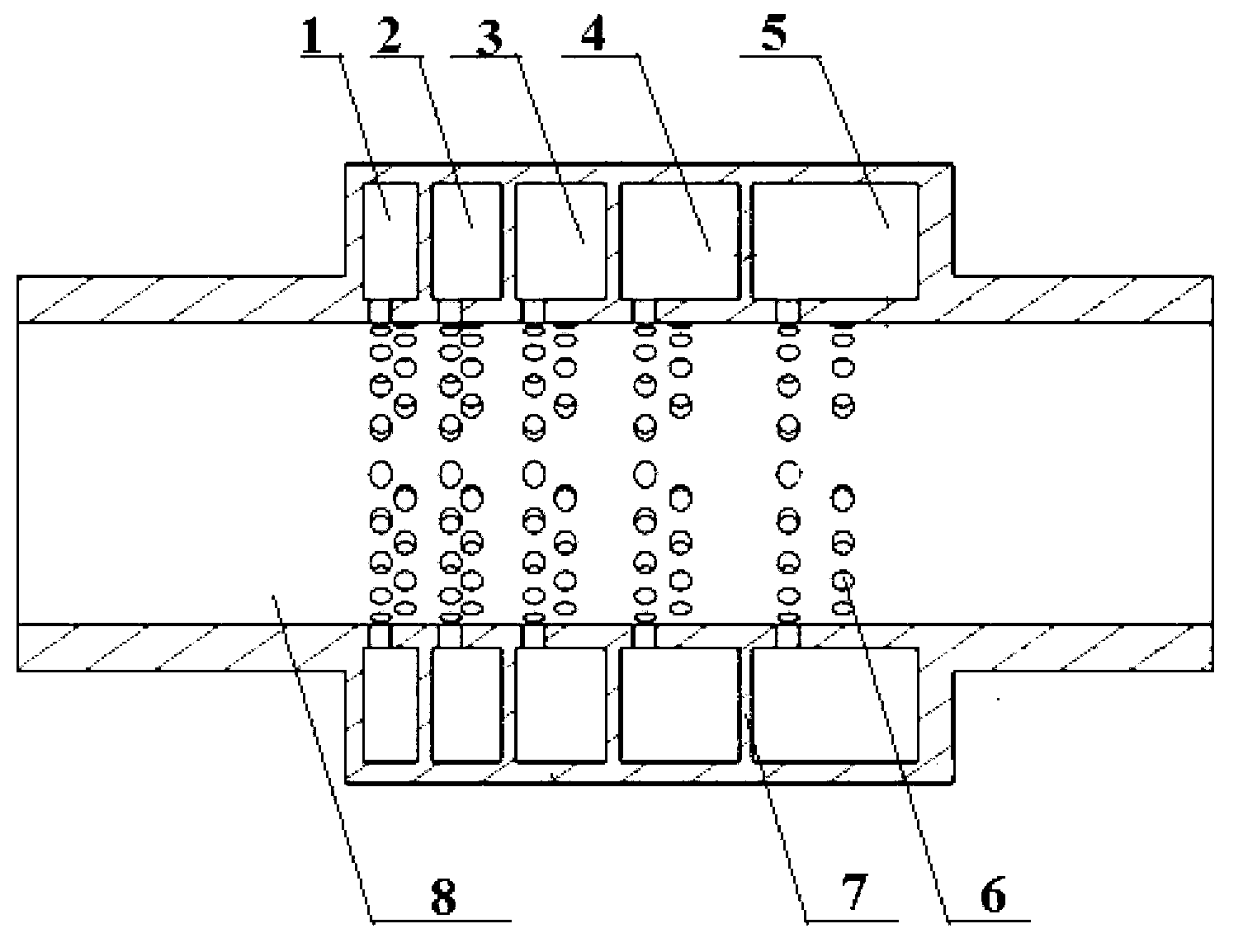

[0024] A muffler for an air assist system of a fuel cell vehicle, the structure of which is as follows Figure 1-2 As shown, it can be installed after the air filter or at the front end of the air filter. The muffler is composed of the air flow main pipe 8 and a number of annular resonant cavities set on the air flow main pipe 8. The partition board 7 is separated, and an opening 6 is provided on the air flow main pipe 8 , and the annular resonant cavity communicates with the air flow main pipe 8 through the opening 6 .

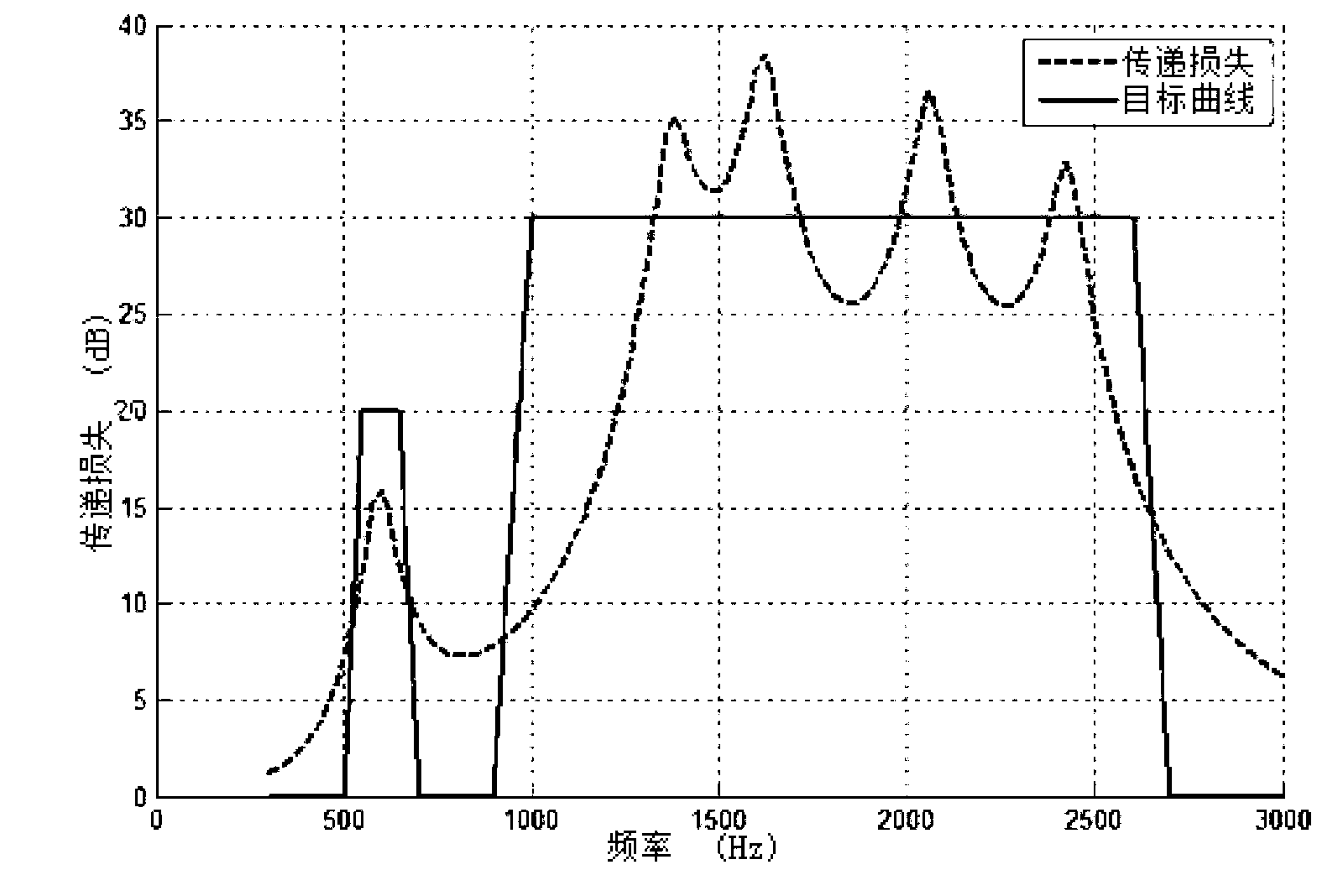

[0025] The airflow main pipe 1 communicates with each annular resonant cavity through at least two groups of openings, and the number of openings in each group matches the size of the annular resonant cavity and the frequency of the attenuated noise. There are four groups of openings in this embodiment. In addition, there are at least two ring resonant cavities, and the sizes of the ring resonant cavities are the same or different. In this embodiment, a firs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com