Turnable bearing with inner ring provided with V-shaped belt groove

A slewing bearing and inner ring technology, applied in bearing components, shafts and bearings, mechanical equipment, etc., can solve problems such as the inability to meet the use requirements of the matching host, and achieve the effect of expanding the scope of use, optimizing the working conditions and preventing collisions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

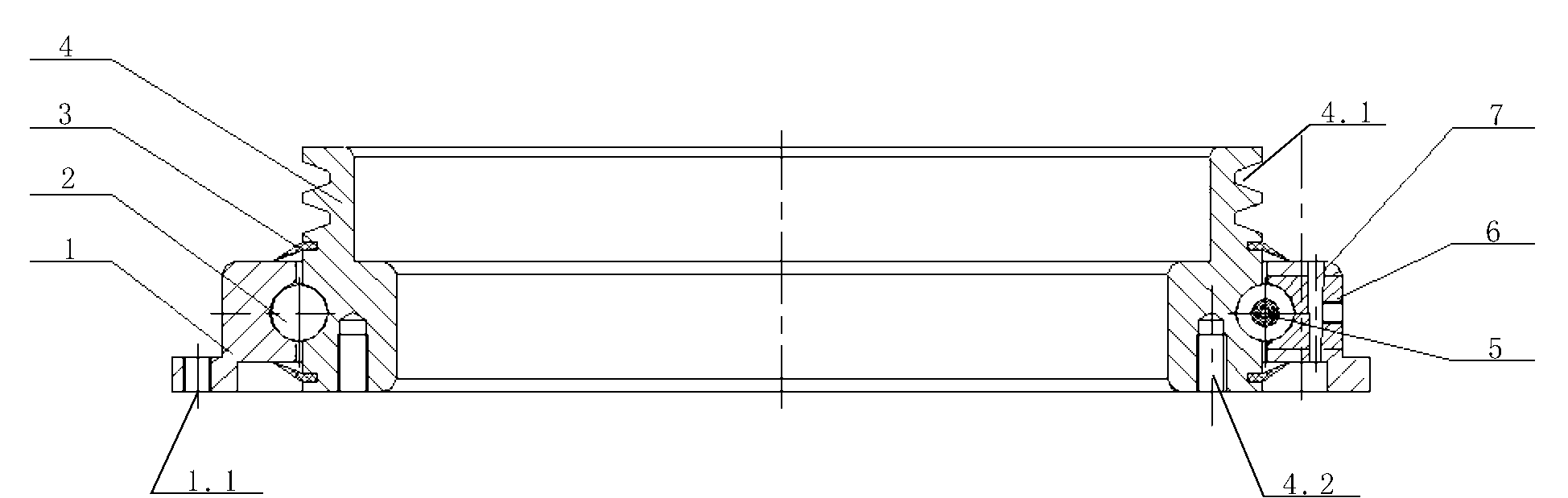

[0019] The invention is a slewing bearing with a V-shaped groove in the inner ring.

[0020] to combine figure 1 , the slewing bearing of the present invention comprises an outer ring 1, rolling balls 2, fin sealing ring 3, inner ring 4, spacer block 5, plug 6 and conical positioning pin 7, an inner raceway is set on the inner diameter end surface of the outer ring 1, and the inner The outer diameter end surface of the ring 4 is provided with an outer raceway, the inner raceway is symmetrical to the outer raceway, and the curvature radii of the inner raceway and the outer raceway both match the radius of the rolling ball 2, and Several rolling balls 2 are installed between the inner raceway and the outer raceway. It is recommended to use four-point contact balls for the rolling balls 2. Spacer blocks 5 are set between adjacent balls 2. The spacer blocks 5 can ensure the safety of the slewing bearing. The rotation accuracy prevents the balls from colliding during rotation and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com