Magnetic fluid dust-proofing and sealing method for wind sensor

A wind sensor, magnetic liquid technology, applied in the direction of engine seal, engine components, mechanical equipment, etc., can solve problems such as hindering the free rotation of the central axis, inaccurate judgment of the rotation angle of the wind flag, and inability to judge whether the blower is working normally, etc. Guaranteed reliability, simple structure, and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

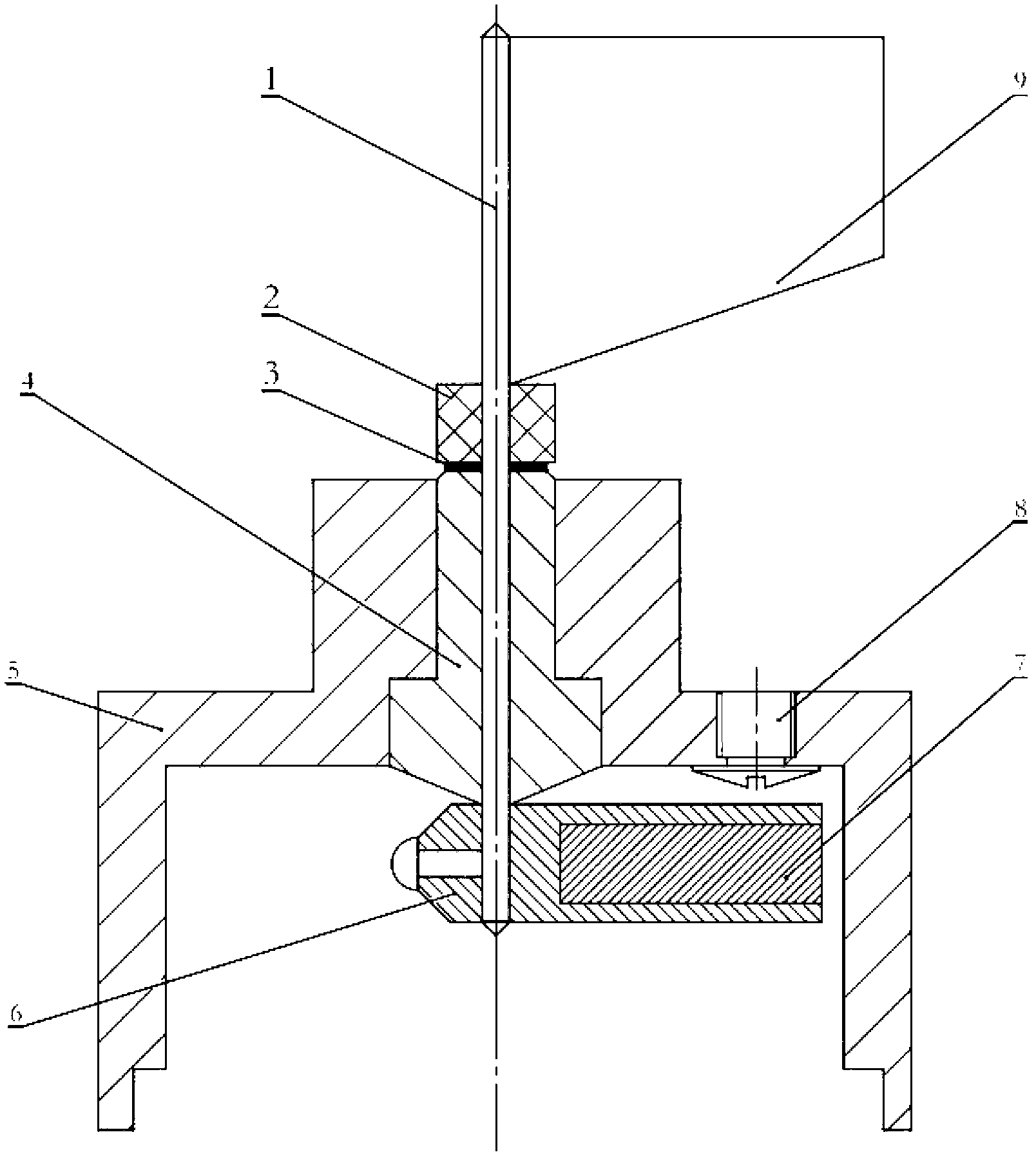

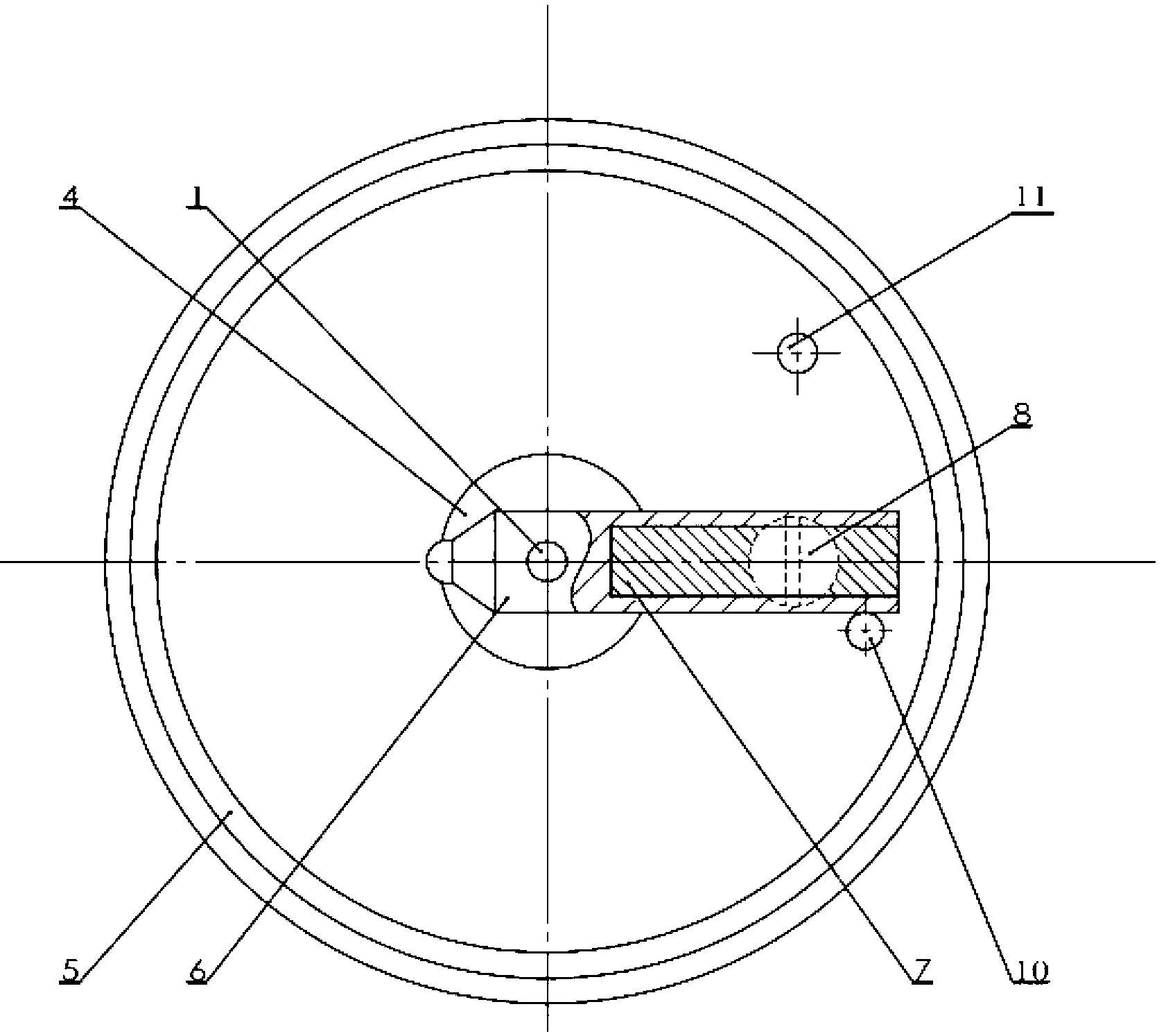

[0016] A magnetic liquid dust-proof sealing method for a wind sensor, comprising a central shaft 1, a rubber magnet 2, a magnetic liquid 3, a central shaft sleeve 4, a casing 5, a swinging magnetic column 6, a magnetic core 7, a magnetic pole screw 8, and a wind flag 9. Set screw 10, set screw 11;

[0017] Connections between the above parts:

[0018] The central shaft sleeve 4 is loaded into the shell 5 and welded at the bottom;

[0019] Connect the magnetic pole screw 8 to the casing 5 by threads, install the positioning screw 10 and the positioning screw 11 on the casing 5, and install the magnetic core 7 into the swinging magnetic column 6;

[0020] Weld the wind flag 9 on the central shaft 1, put the central shaft 1 into the rubber magnet 2, and the central shaft 1 and the rubber magnet 2 have an interference fit to ensure that the rubber magnet 2 will rotate with the central shaft 1;

[0021] Put the central shaft 1 into the central shaft sleeve 4 and the swing magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com