Static material layer thickness detection device between dielectric balls

A material layer thickness and detection device technology, applied in the direction of mechanical thickness measurement, etc., can solve the problems of large data error, difficult to measure the thickness of the material layer between the medium balls, low energy utilization rate, etc., and achieve the effect of improving the grinding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

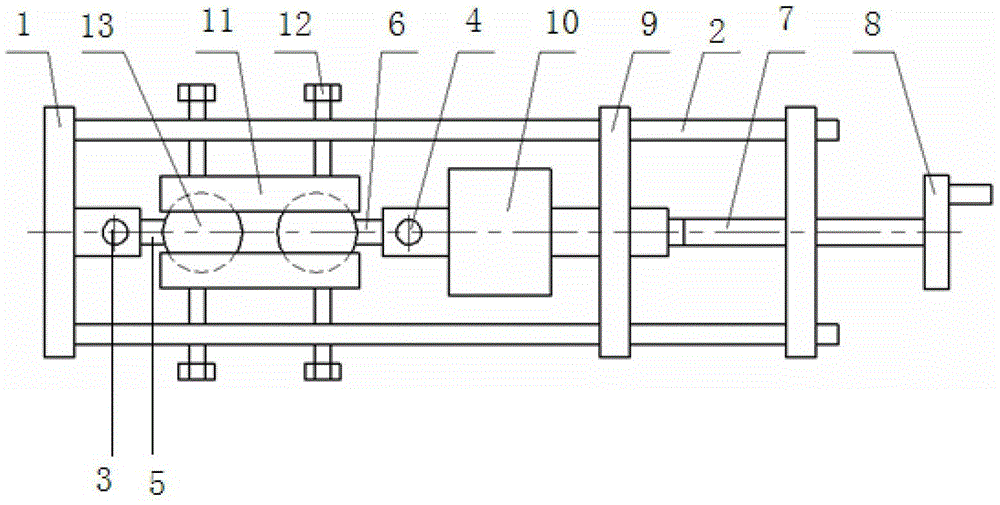

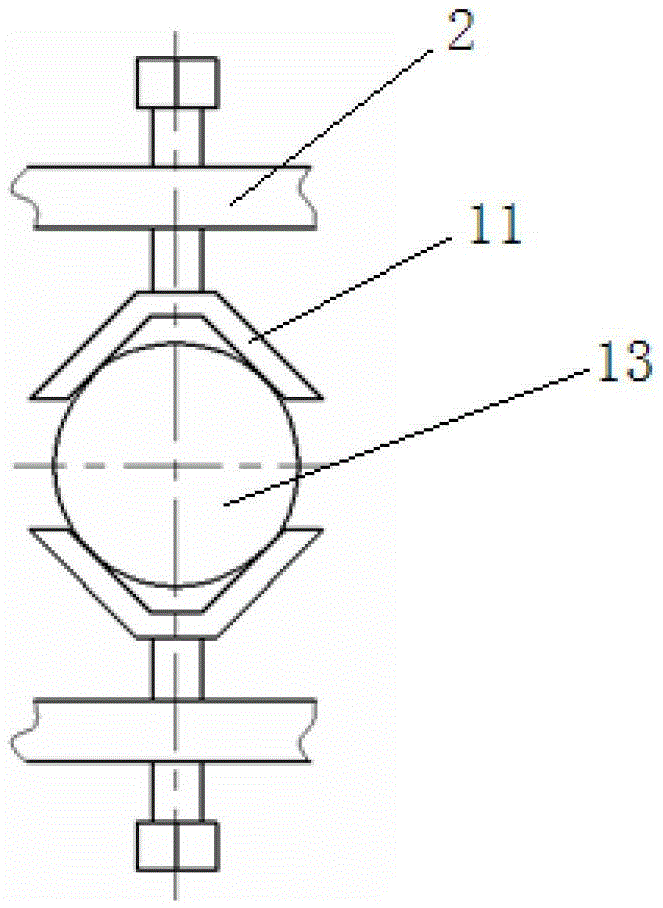

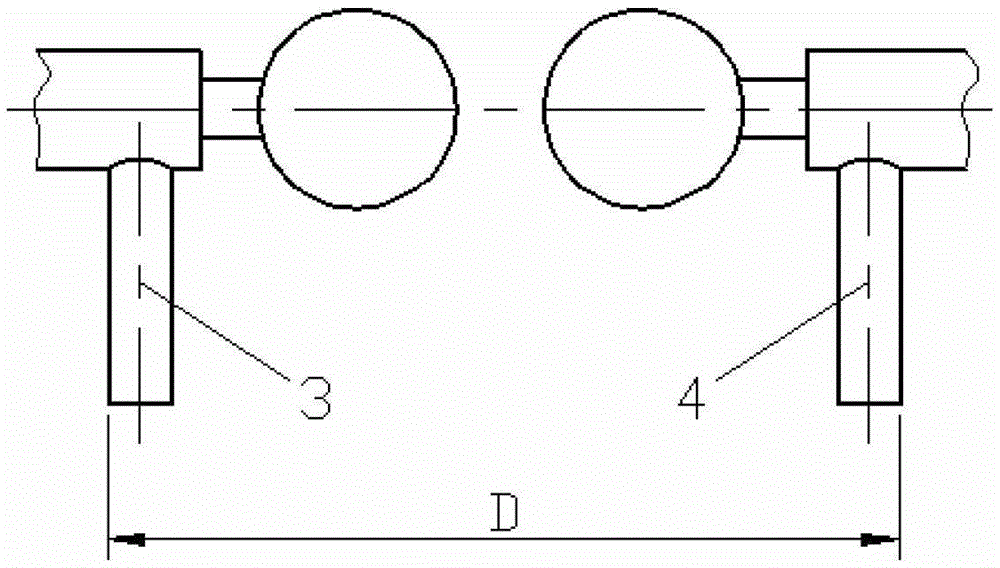

[0015] refer to Figure 1 to Figure 3 , a static material layer thickness detection device between medium balls, including a bracket 1, a V-shaped guide plate 11, a first ejector rod 5, a second ejector rod 6, a first scale rod 3, a second scale rod 4, a dynamometer 10, Movable seat 9, guide rod 2, screw mandrel 7 and handwheel 8, described support 1 upper and lower ends are respectively fixed with described guide rod 2, described guide rod 2 is provided with described movable seat 9 and described movable The seat 9 can move left and right along the guide rod 2; the first push rod 5 is fixedly provided at one end of the support 1, and the first scale rod 3 is fixedly provided on the first push rod 5; One end of the rod 7 is rotationally connected with the handwheel 8, and the other end is threadedly connected with the movable seat 9, and the handwheel 8 pushes the screw rod 7 to rotate so that the movable seat 9 moves left and right along the guide rod 2 The movable base 9 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com