Pulse vortexing defect quantitative detection method and detection system

A quantitative detection method and pulsed eddy current technology, applied in the direction of material magnetic variables, can solve the problems of high cost, quantitative estimation of defects, and inability to quantitatively estimate the size of defects, and achieve the effect of low cost, simple method and process, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

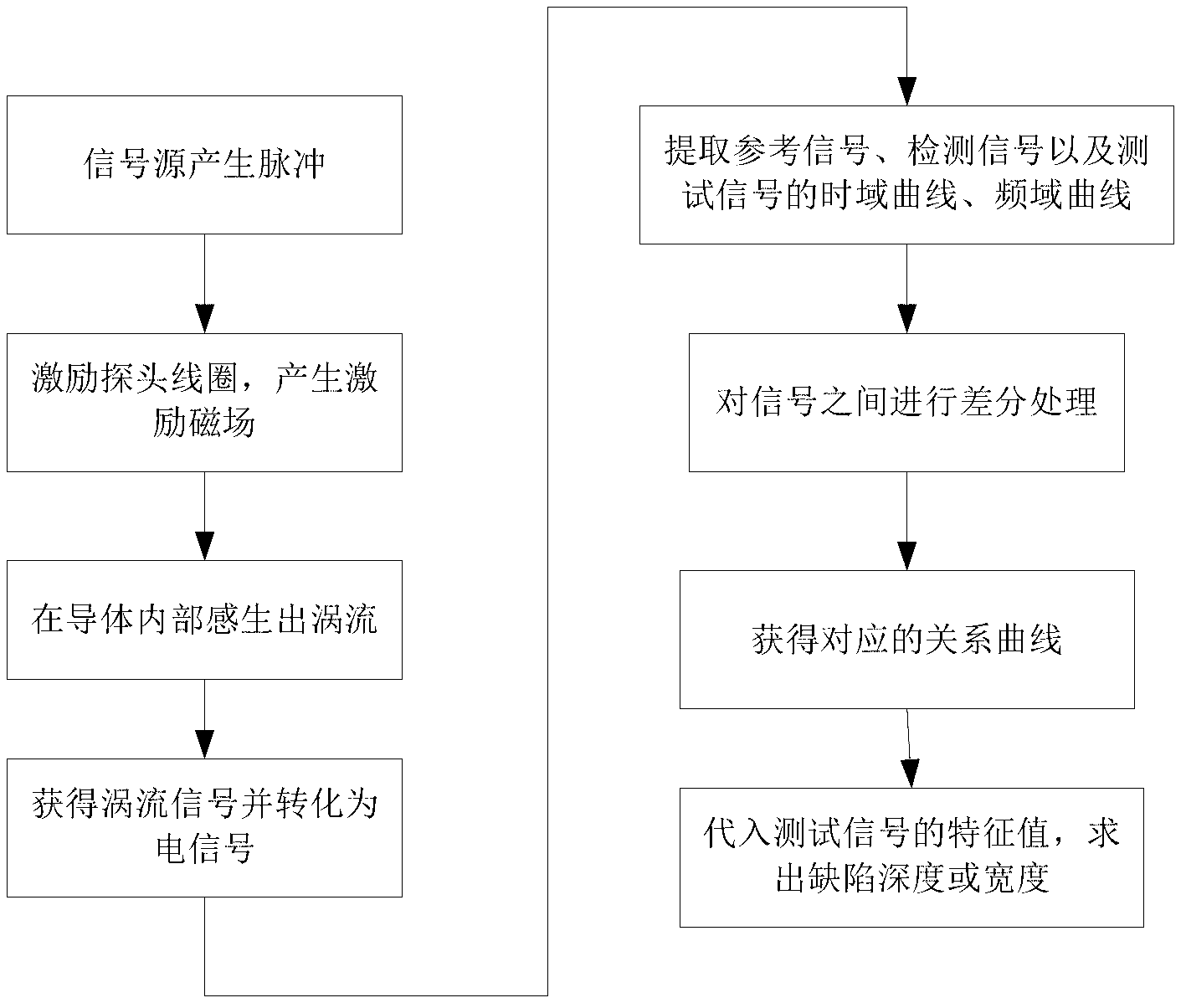

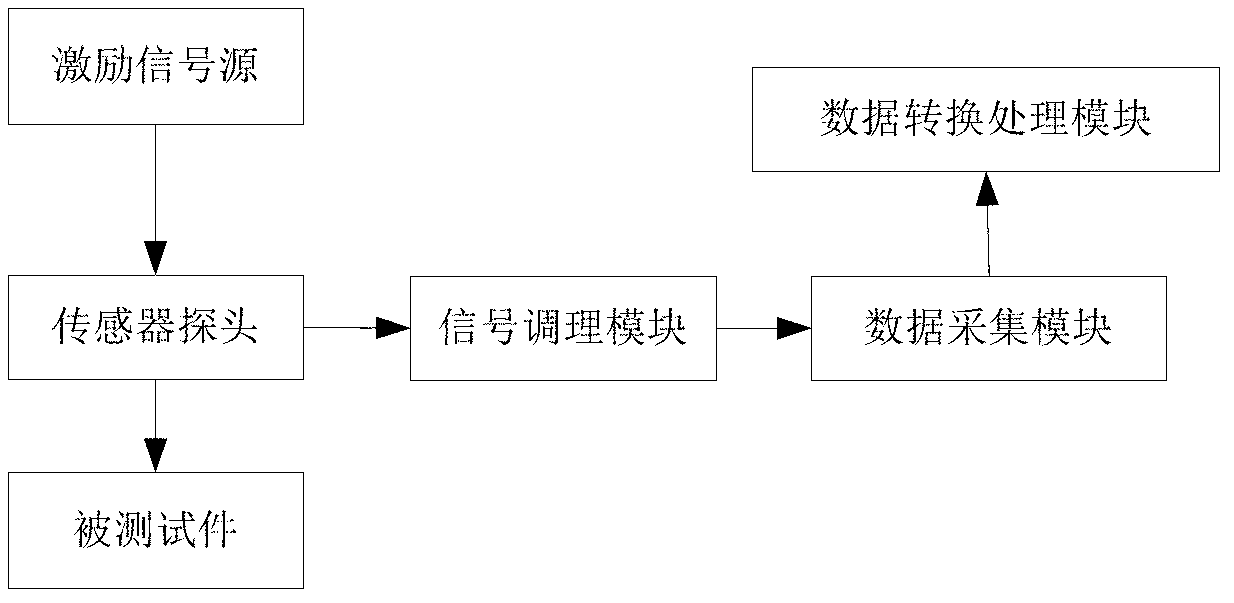

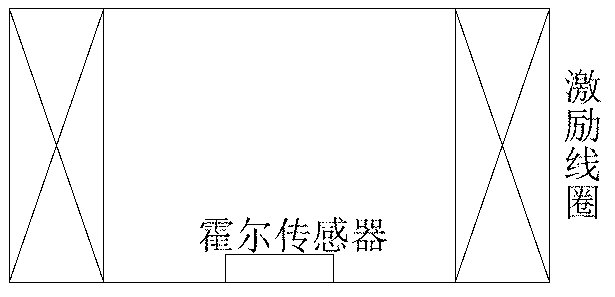

[0041] The flow chart of the pulsed eddy current defect quantitative detection method in the embodiment of the present invention is as follows figure 1 shown, including:

[0042] Step 1. When the depth or width of the defect is known, obtain the algebraic expression of the relationship curve between the peak value of the time-domain signal difference between the response signals and the depth or width of the surface defect or the fundamental frequency of the frequency-domain signal between the response signals The algebraic expression of the relationship curve between the differential peak value and the depth or width of the surface defect, specifically includes the following sub-steps:

[0043] S11, generating a pulse excitation signal with adjustable frequency and duty ratio;

[0044] S12. Excite the probe coil to generate an excitation magnetic field,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com