Method for starting permanent magnet synchronous motor without position sensor

A technology of permanent magnet synchronous motor and starting method, which is applied to control generator, motor generator control, electronic commutation motor control, etc., can solve the problems of motor out of step, large starting torque, and inability to ensure constant motor starting torque.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

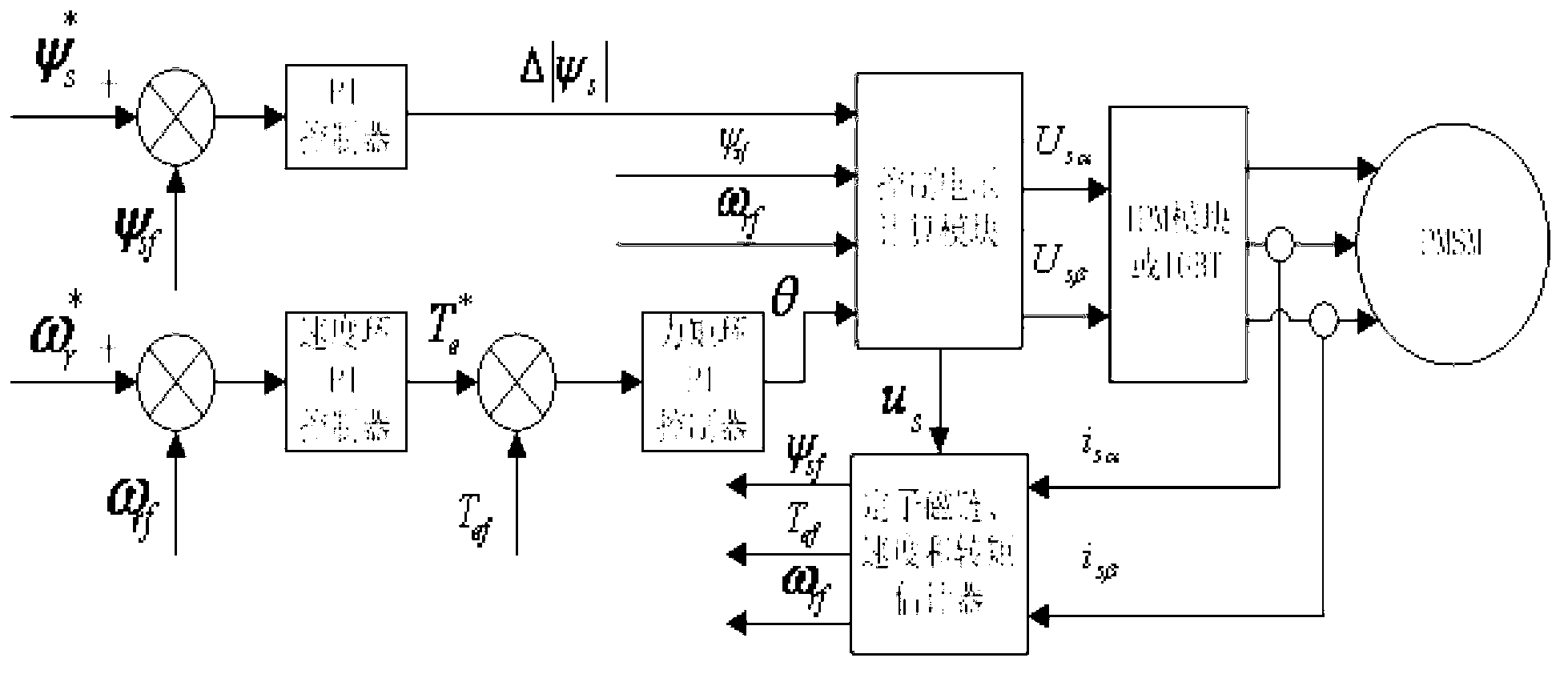

[0052] Embodiment 1. A starting method for a permanent magnet synchronous motor without a position sensor, wherein: the open-loop control starting of the permanent magnet synchronous motor is realized by using a closed-loop control method for stator flux linkage.

Embodiment 2

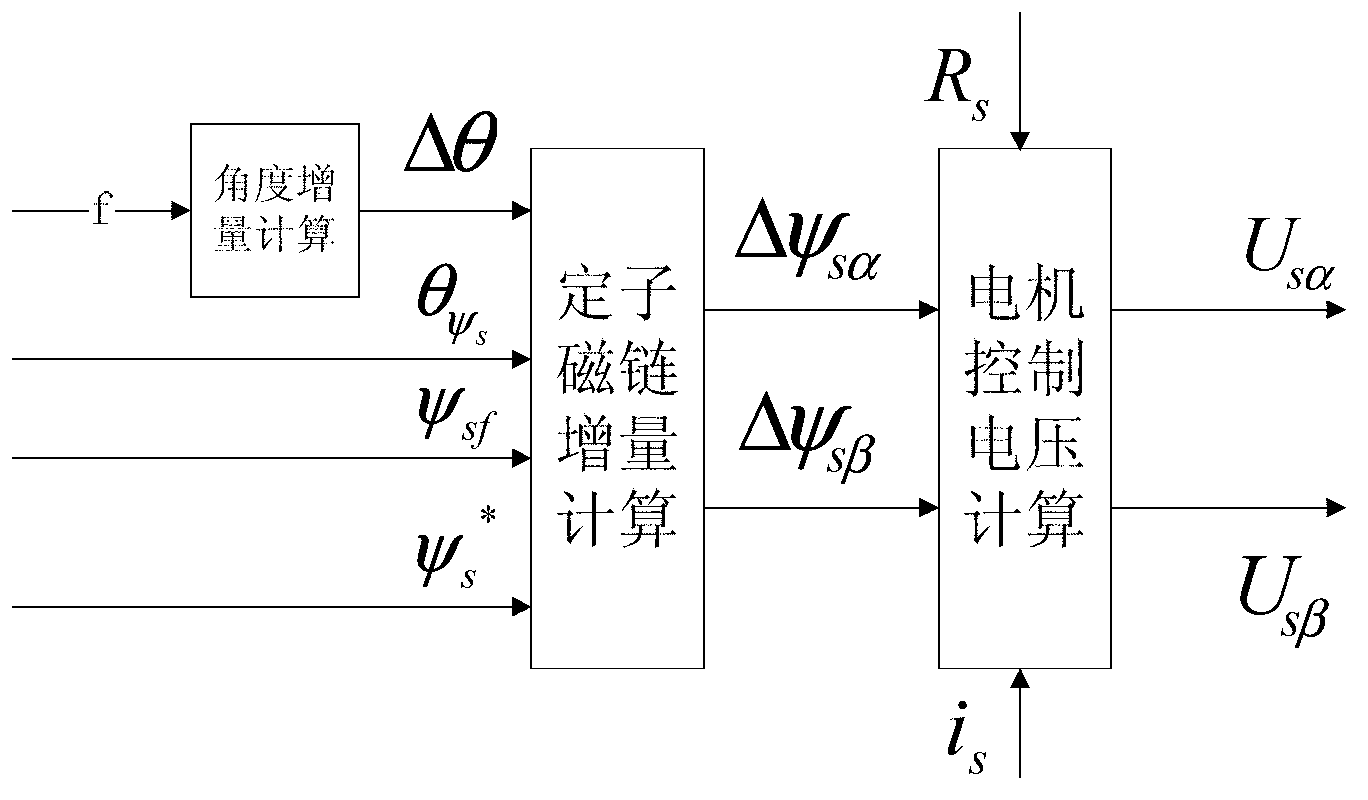

[0053] Embodiment 2, as figure 1 As shown, a permanent magnet synchronous motor starting method without a position sensor, wherein: the step of closed-loop control of the stator flux linkage is: based on the estimated stator flux increment Δψ, and the detected stator resistance R s and stator current i s Finally, the stator output voltage U is calculated s , the stator output voltage U s The calculation method is:

[0054] U sα = Δψ sα ΔT + R s i sα ;

[0055] U sβ = Δψ sβ ΔT + R s i sβ ;

[0056] In the formula, the ΔT mentioned is the update period of the stator output voltage, U sα ...

Embodiment 3

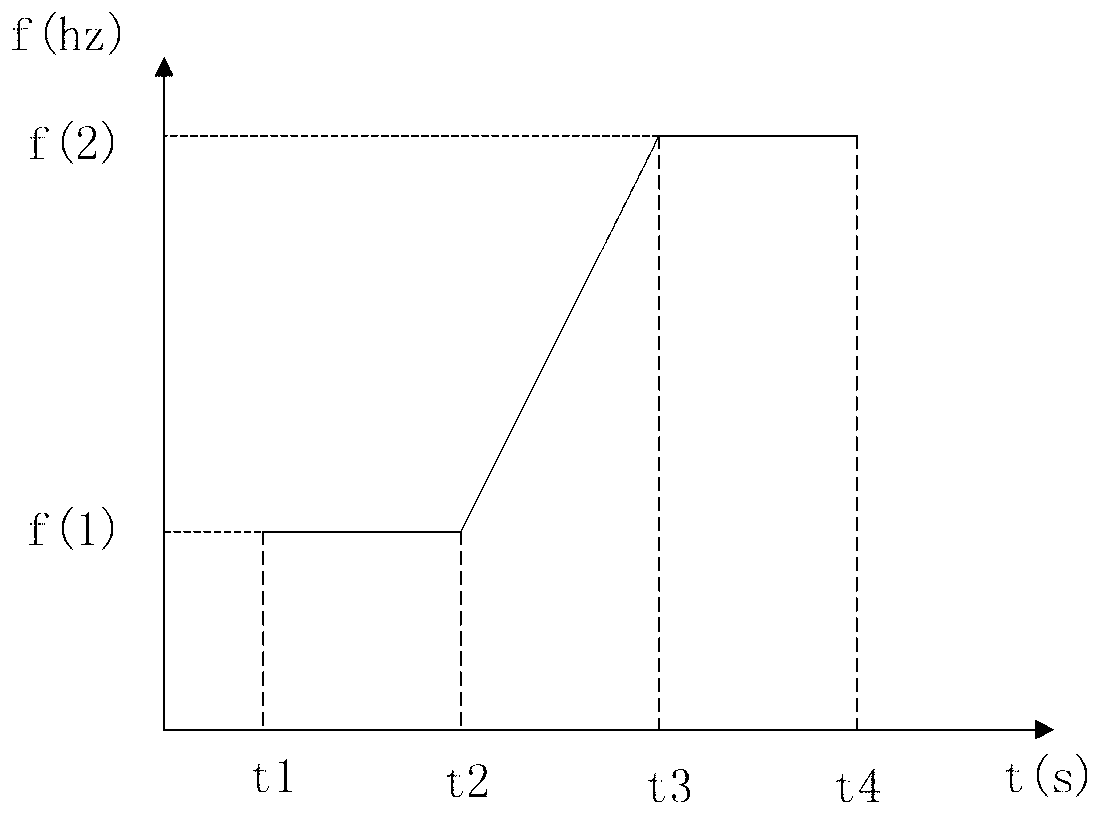

[0057] Embodiment 3, a permanent magnet synchronous motor starting method without a position sensor, wherein: the estimation step of the stator flux increment Δψ is: based on the stator output voltage frequency f, the stator flux estimation vector angle , Stator flux estimation vector magnitude ψ sf , Stator flux linkage vector amplitude setting value Calculate the stator flux increment Δψ, and the calculation method of the stator flux increment Δψ is:

[0058] Δ ψ s α = ψ s * cos ( θ ψ s + Δ θ ) ? ψ s f cos ( θ ψ s ) ;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com