A bending part control mechanism and endoscope equipment thereof

A control mechanism and bending part technology, applied in the field of endoscopy, can solve the problems of complex assembly of the control mechanism, achieve the effects of simplifying the transfer and adjustment process, flexible assembly, and saving the trouble of controlling the wire rope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

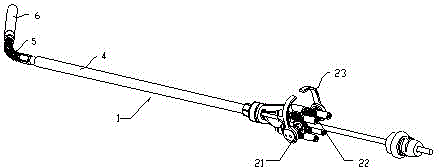

[0032] like image 3 As shown, an ultrasonic probe laparoscope 1 generally includes a bending part control mechanism 2 , a rigid insertion tube 4 inserted into the abdominal cavity, a bending part 5 that can bend in multiple directions, and an ultrasonic sensor 6 . When working, the ultrasonic probe laparoscope 1 is connected to the ultrasonic host through a cable, and the rigid insertion tube 4, the bending part 5, and the ultrasonic sensor 6 are inserted into the abdominal cavity of the human body, and the user controls the bending part 5 and the ultrasonic sensor 6 through the bending part control mechanism 2 Swing to adjust the ultrasound imaging scan angle and position.

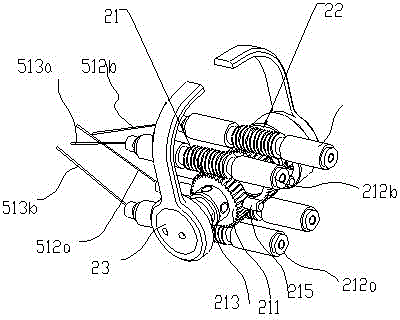

[0033] like figure 1 , 2 As shown, the bending part 5 includes a curved snake pipe and a snake pipe joint flange; the curved snake pipe includes a number of snake pipe joints and steel wire ropes (512a, 512b) and (513a, not shown in the figure) for connecting the snake pipe joints in series ). One en...

Embodiment 2

[0047] The embodiment of the present invention also discloses a device with the bending part control mechanism as described in the first embodiment. The device may be an endoscope device. The structure of the bending part control mechanism is as described in the first embodiment. This will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com