Novel electrical dust collector

An electrostatic precipitator and a new type of technology, applied in electrode structure, electrostatic separation, electrode cleaning and other directions, can solve the problems of poor rapping cleaning effect, difficult emission standards, and difficulty in rapping cleaning thoroughly, etc., to improve dust removal efficiency, Increase the dwell time, the effect of which is conducive to capture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

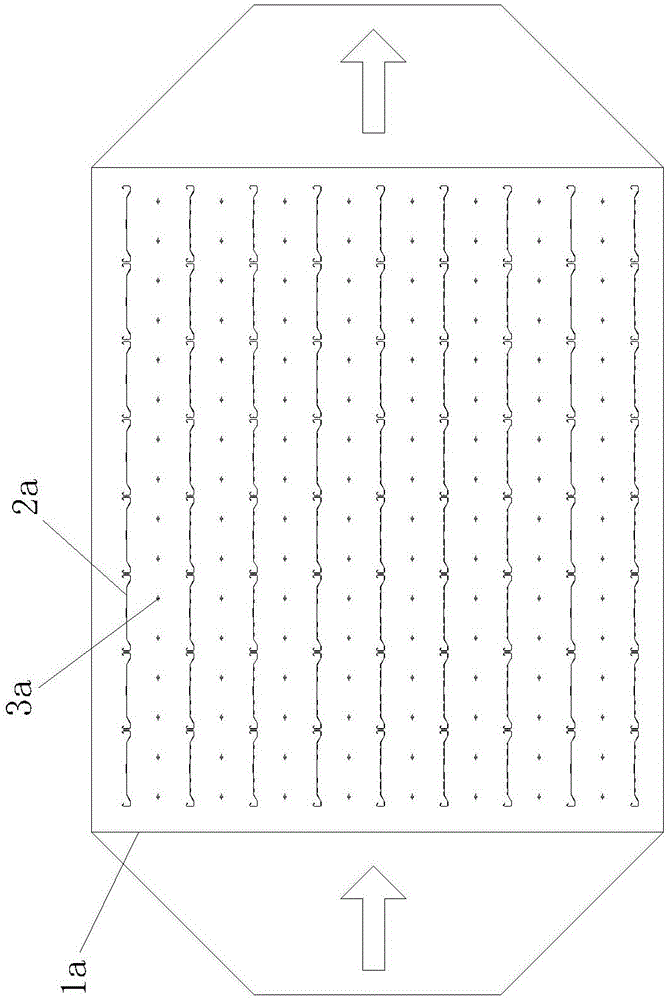

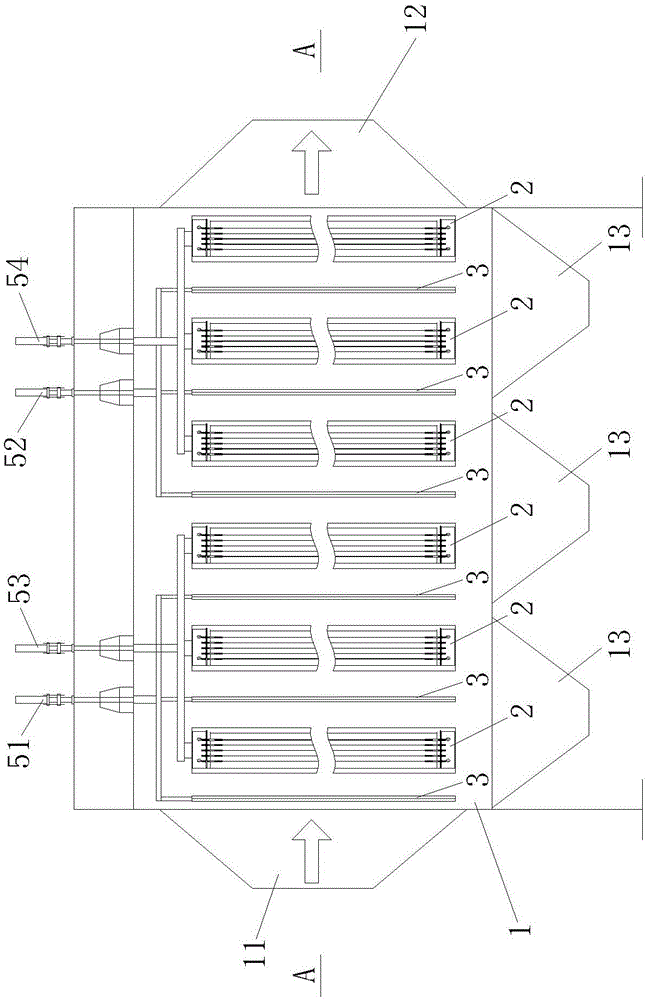

[0032] Embodiment one, Figure 2 to Figure 6 As shown, a new type of electrostatic precipitator includes a housing 1, multi-row electrode plate rows 2, and multi-row corona wires 3. One side of the housing 1 is provided with a trumpet-shaped air inlet 11, and the other side of the housing is provided with There is a trumpet-shaped air outlet 12, and the lower part of the housing is provided with an ash hopper 13, and the corona wires 3 and the electrode plate rows 2 are alternately placed in the interior of the housing 1 along the direction of air flow; preferably six rows of corona wires 3 and The six rows of plate rows 2 form an electric field, the six rows of corona wires 3 are all connected to the negative high voltage power supply 4, the six rows of plate rows 2 are all grounded, and the tops of the first, second and third rows of corona wires 3 along the airflow direction Connect the first group of rapping mechanisms 51, connect the top of the fourth, fifth and sixth row...

Embodiment 2

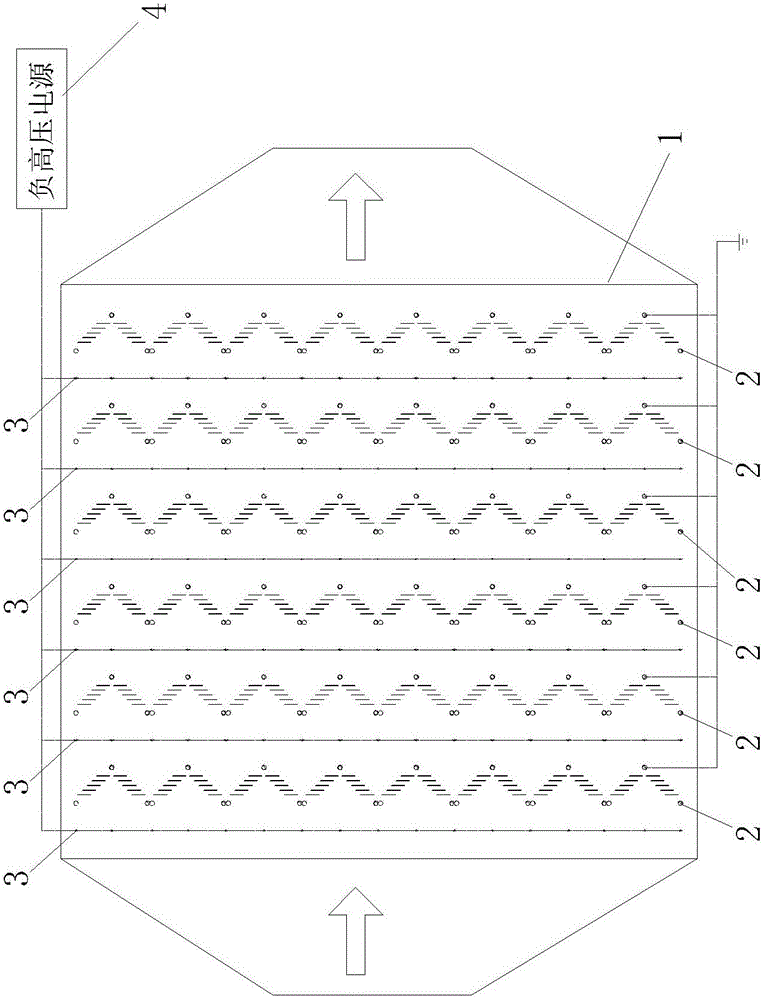

[0043] Embodiment two, Figure 7 , Figure 8 As shown, the difference from Embodiment 1 is that the first, third, fifth and sixth rows of corona wires 3 along the airflow direction are connected to the negative high voltage power supply 4, and the second and fourth rows of corona wires 3 along the airflow direction Connect the positive high-voltage power supply 6, and the six rows of plate rows 2 are all grounded;

[0044] The tops of the first and third rows of corona wires 3 along the airflow direction are connected to the first group of rapping mechanisms 51, and the tops of the second and fourth rows of corona wires 3 are connected to the second group of rapping mechanisms 52 along the airflow direction. The tops of the fifth and sixth rows of corona wires 3 in the direction are connected to the third group of rapping mechanisms 53, and the tops of the first, second and third rows of plate rows 2 are connected to the fourth group of rapping mechanisms 54 along the airflow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com