Multi-section bending radius numerical-control die-free bending shaping method and equipment

A technology of bending radius and forming equipment, which is applied in the direction of heat exchange equipment, etc., can solve the problem that the arc processing of multiple sections with different bending radii is difficult to realize, and achieve the effect of avoiding overturning and avoiding wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

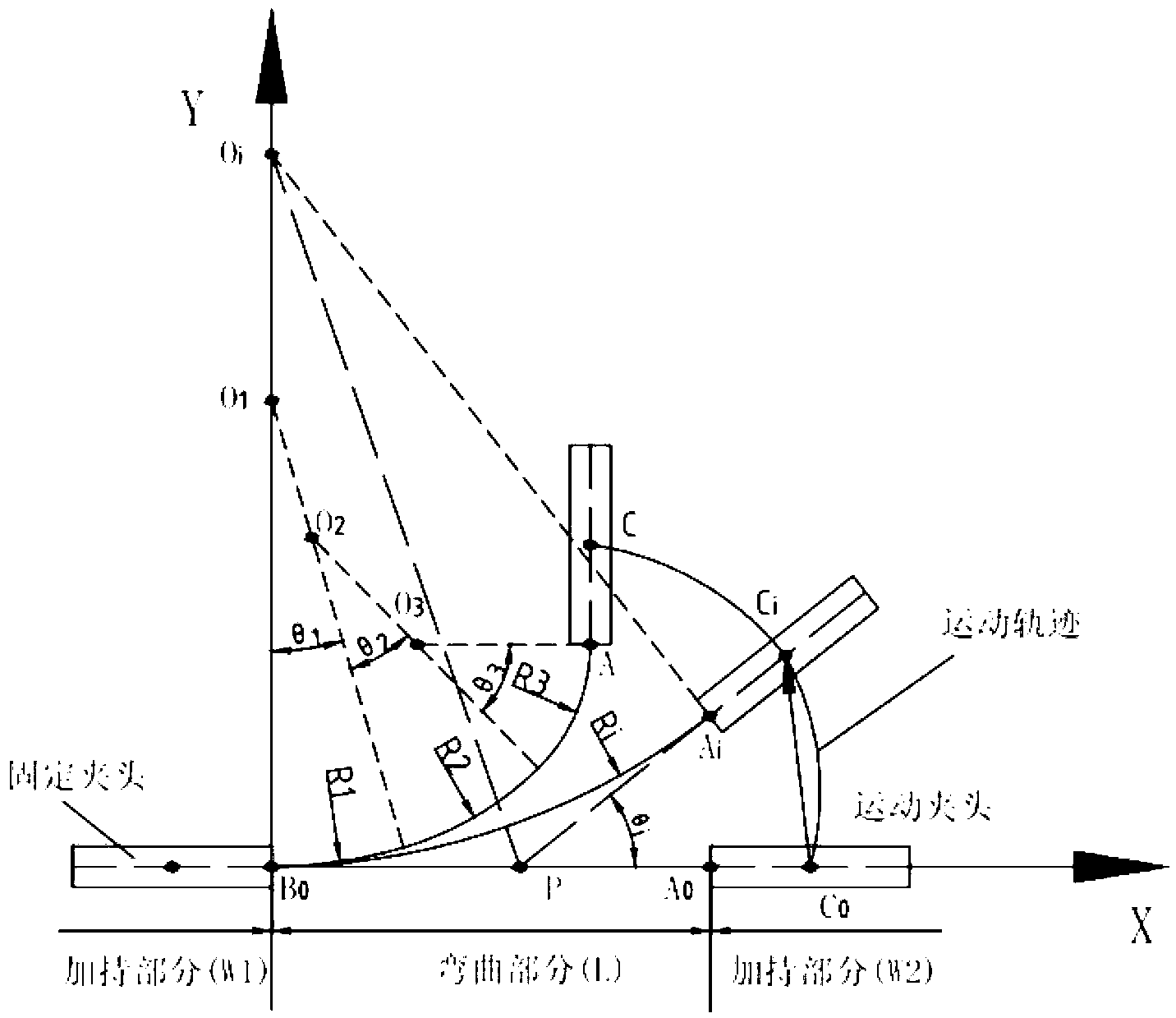

[0042] Such as figure 1 As shown, the principle diagram of the method of the present invention, in the figure: the workpiece is divided into three parts: the holding part W1, the bending part L, and the holding part W2. The holding part W1 is clamped with a fixed chuck, the holding part W2 is clamped with a moving chuck, and the bending part L is from the end B0 of the fixed chuck to the head A0 of the moving chuck. Point C is the midpoint of the moving chuck after bending. The center of the moving chuck moves from C0 to Ci, and then to point C. The radius of curvature Ri is the radius of curvature when the bending angle is θi. figure 1 Among them, O1, O2, and O3 are the centers of circles when the radii of curvature are R1, R2, and R3, respectively. figure 1Among them, O1, O2, and O3 are the centers of circles when the radii of curvature are R1, R2, and R3, respectively. Therefore, as long as the starting and ending positions of the workpiece bending are known, as well as...

Embodiment 2

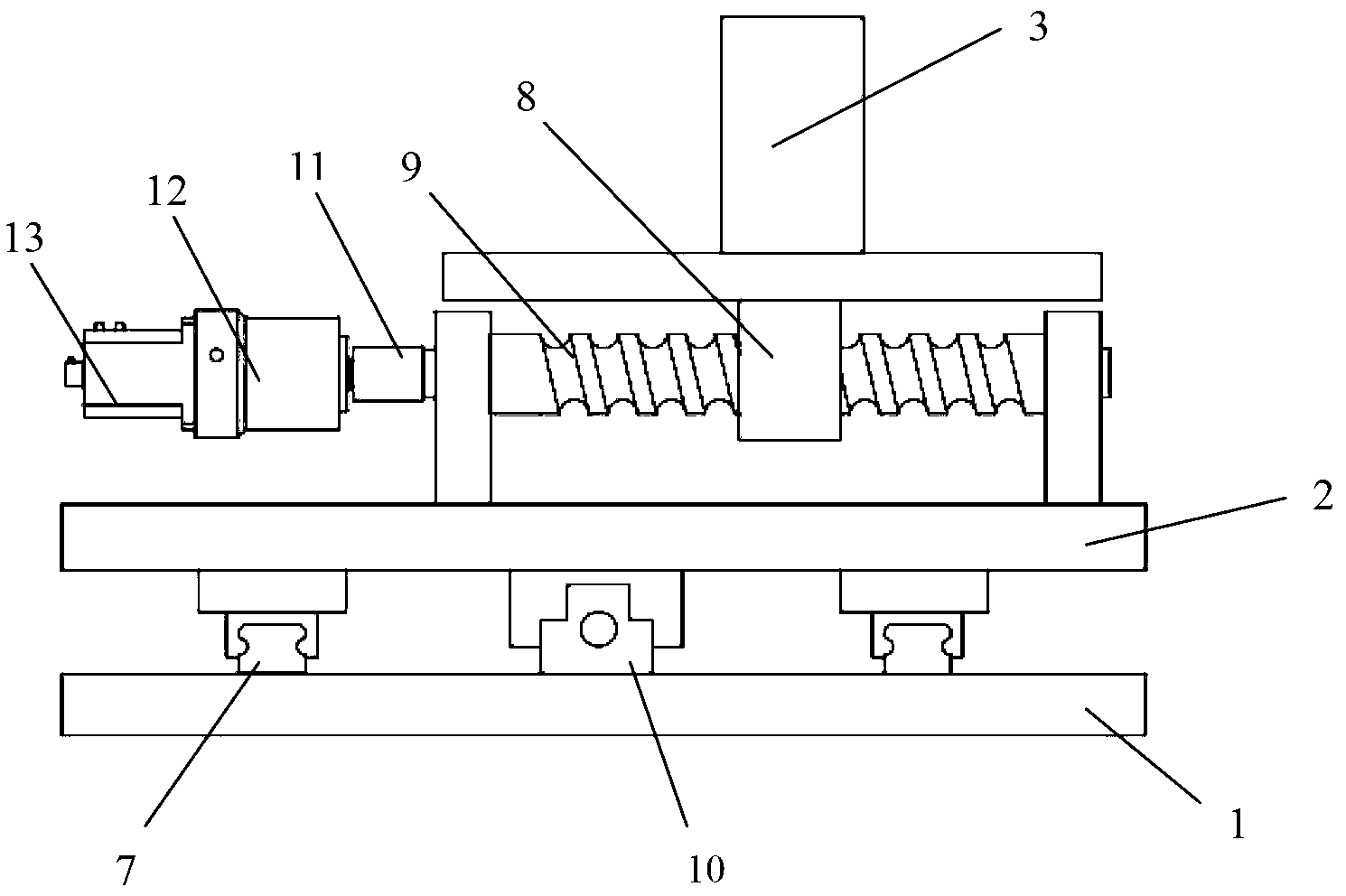

[0063] This embodiment provides a dieless bending and forming equipment, including a translation chuck and a rotation chuck, a driving device, a bending platform, and a numerical control system. Such as Figure 2-3 As shown in the figure: 1: base, 2: sliding platform, 3: translation chuck, 4: rotating chuck, 7: guide rail, 8: lead screw connection block, 9: lead screw, 10: lead screw support seat , 11: coupling, 12: reducer, 13: servo motor. Wherein: the base 1, the sliding platform 2, and the guide rail 7 constitute the bending platform; the lead screw connection block 8, the lead screw 9, the lead screw support seat 10, the shaft coupling 11, the reducer 12, and the servo motor 13 constitute the driving device.

[0064] The guide rail 7 is arranged on the base 1 and the sliding platform 2, the guide rail on the bottom plate 1 and the guide rail on the sliding platform are perpendicular to each other, and the translation chuck 3 is connected to the lead screw 9 on the slidin...

Embodiment 3

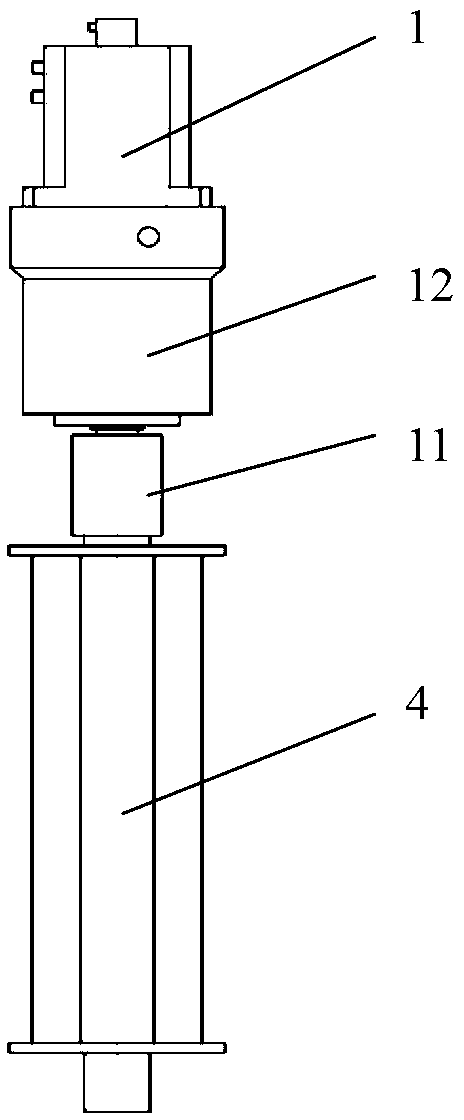

[0068] In another embodiment of the present invention, the used dieless bending forming equipment such as Figure 4 As shown, the difference from Example 2 is that two guide rails parallel to the Y direction are installed on the base 1 to support and guide the linear movement of the sliding platform 2 in the Y direction, and two guide rails parallel to the front are installed on the sliding platform 2. The guide rail is used to support and guide the linear movement of the translation chuck in the X direction. There is a sprocket with a small modulus in the reduction box 6, which drives the large sprocket below the rotating chuck 4 through the chain, thereby driving the rotating chuck 4.

[0069] Such as Figure 5 As shown, the working steps of this equipment are: clamp the workpiece after passing through the translational chuck 3, and then pass through the rotating chuck 4, control the speed of the servo motor according to the numerical control program, and then control the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com