Evaluation method for operation reliability of milling cutter

A milling processing and reliability technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of reducing the processing quality, affecting the processing accuracy and surface roughness of the workpiece, affecting the safety and normal operation of the processing system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

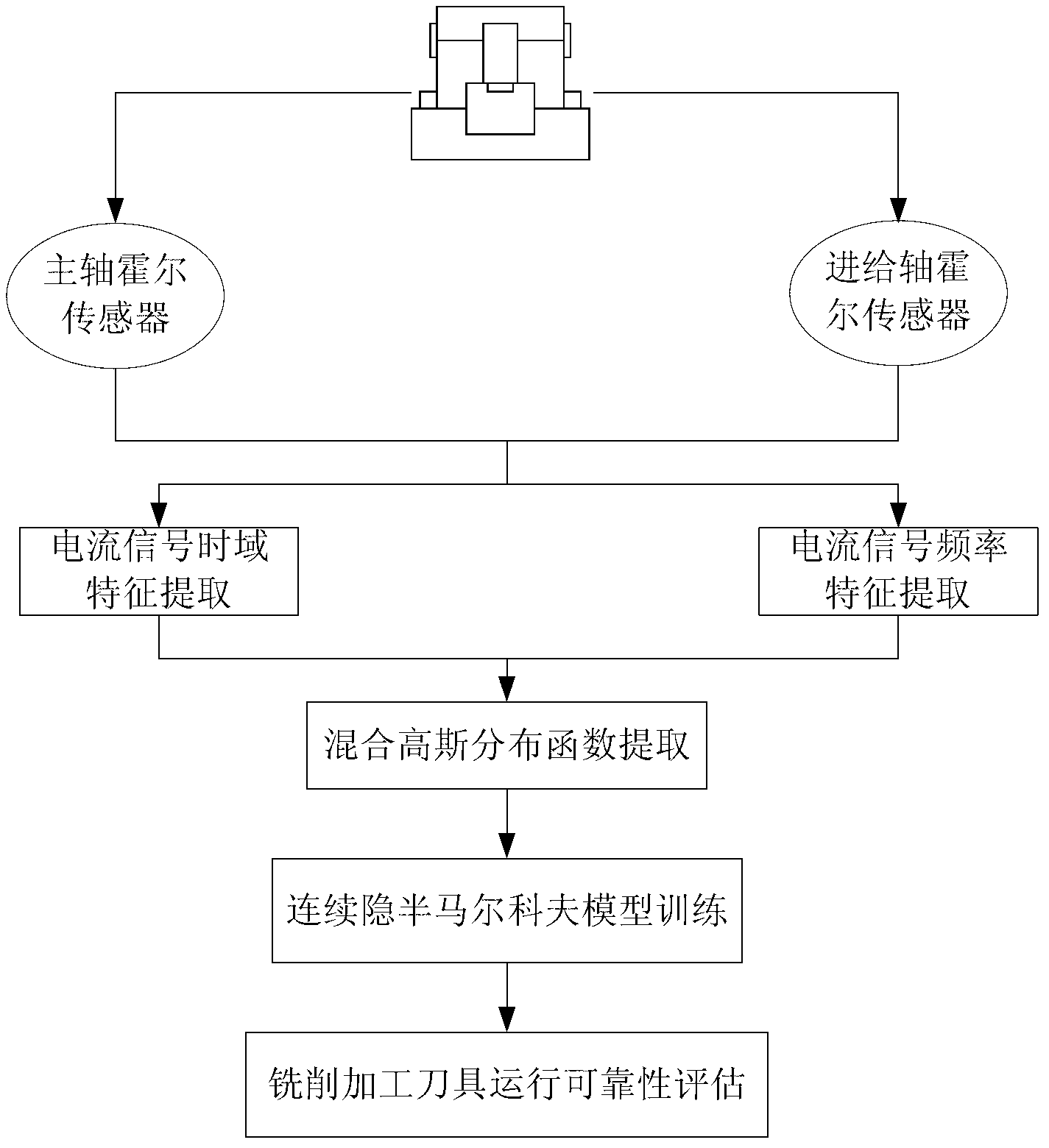

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. The method of the invention first collects the current signals of the main shaft and the feed shaft of the processing machine tool through the Hall sensor, then uses the wavelet analysis method to perform feature extraction, and then performs parameter estimation through the continuous hidden semi-Markov model, and uses the Chepman-Kolmo Gorlov's differential equation calculates the operational reliability level of milling tools to provide decision support for preventive maintenance.

[0020] Such as figure 1 Shown, the present invention comprises the following steps:

[0021] The first step is to determine the running state of the milling tool.

[0022] According to the design data and use history of the milling tool, determine the total number M of its operating status. Milling tool running state set is expressed as S={S 1 ,S 2 ,...,S m ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com