Towing vehicle capable of being used for both roads and rails

A technology for road and rail tractors, applied in the field of vehicles, can solve the problems of reduced traction capacity, small traction force, and small adhesion of turbines, etc., and achieve the effects of reducing site requirements, improving traction capacity, and large traction capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

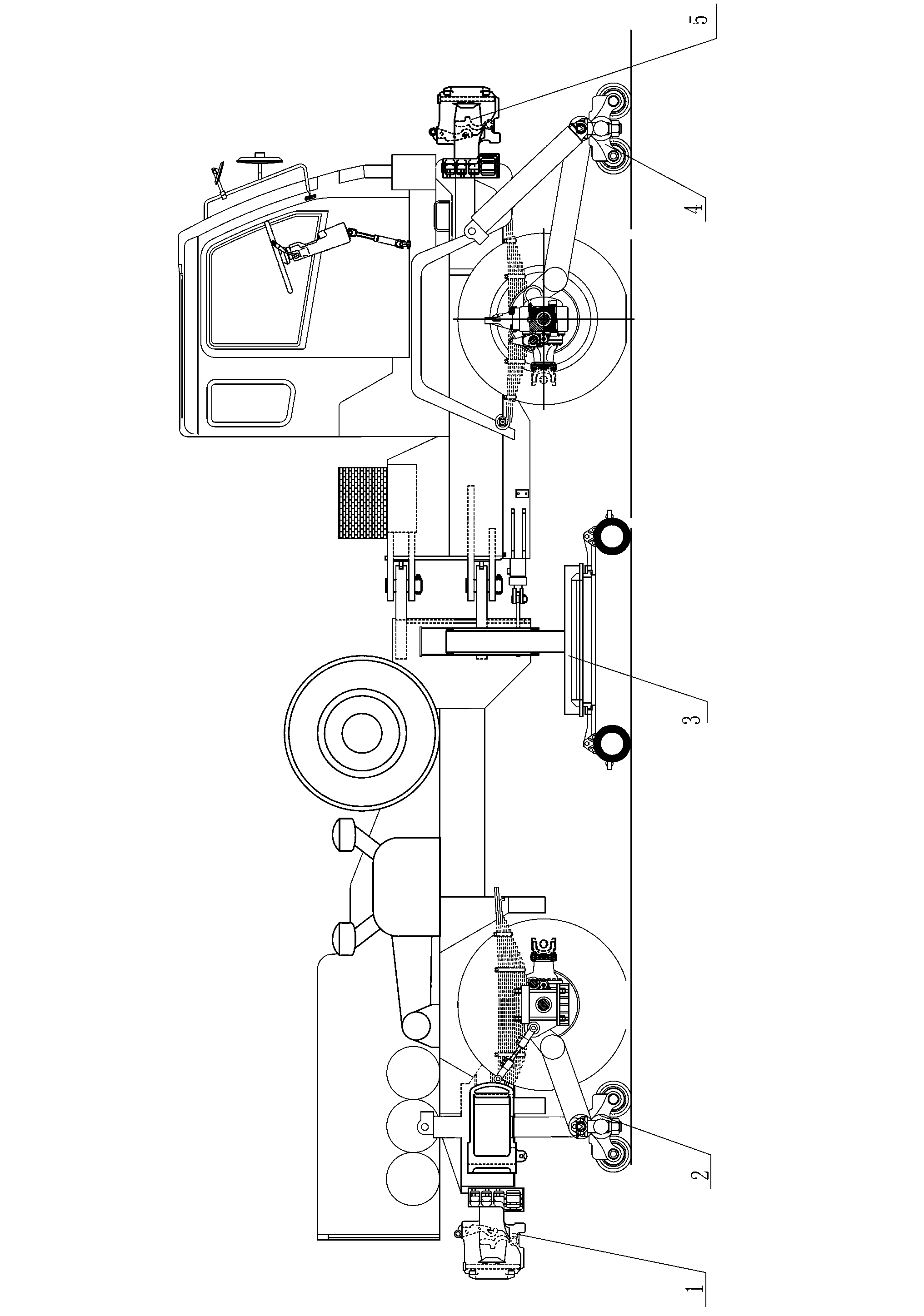

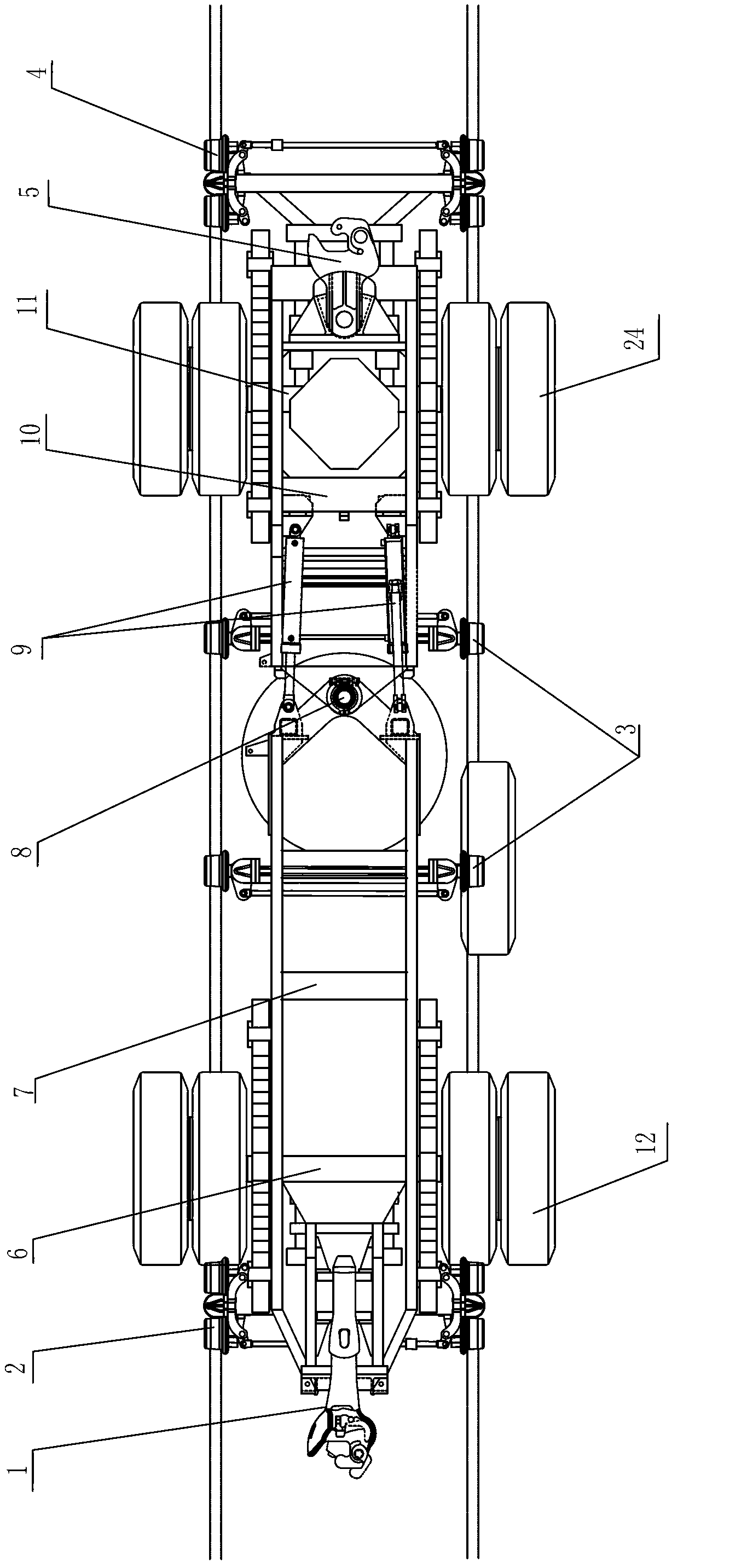

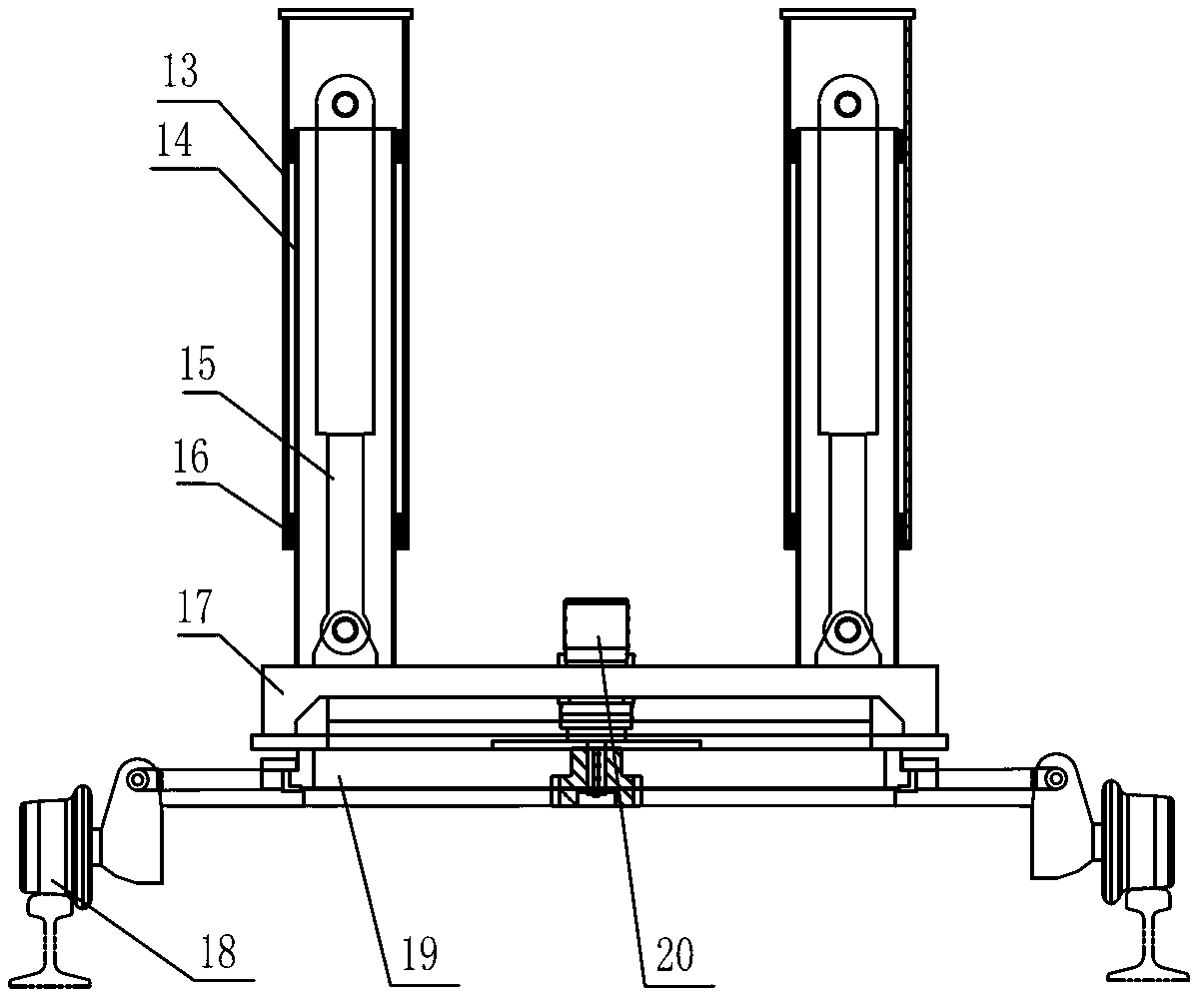

[0020] The schematic diagram of the road-rail dual-purpose tractor of the present invention is as figure 1 , figure 2 Shown, comprise vehicle frame, front axle 11, rear axle 6, front traction mechanism 5, rear traction mechanism 1, front guide mechanism 4 and rear guide mechanism 2, front wheel 24 is installed on the described front axle 11, described rear Rear wheels 12 are mounted on the bridge 6 . Among them, the front guide mechanism 4, the rear guide mechanism 2, the front traction mechanism 5 and the rear traction mechanism 1 are the same as the special road-rail dual-purpose tractor in the field, so as to ensure the stability and traction performance when driving on the track. The vehicle frame is an articulated vehicle frame, and the articulated vehicle frame includes a front vehicle frame 10 and a rear vehicle frame 7 , an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com