Embedded type detachable movable main needle clamp and needle block

A technology of main needle and needle clamp, applied in the field of knitting machine main needle, can solve the problems of high cost, difficult replacement, inconvenient replacement, etc., and achieve the effect of light weight, weight reduction and vibration reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

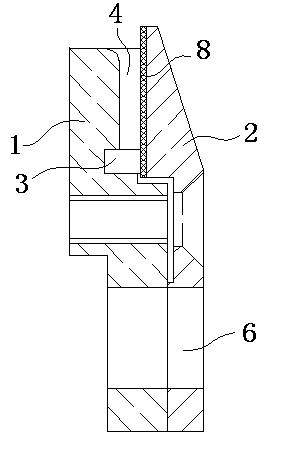

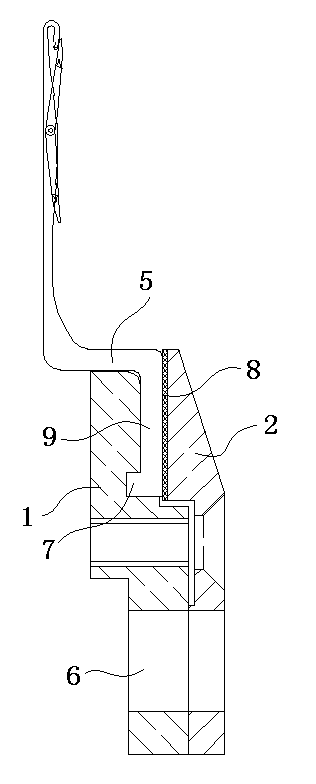

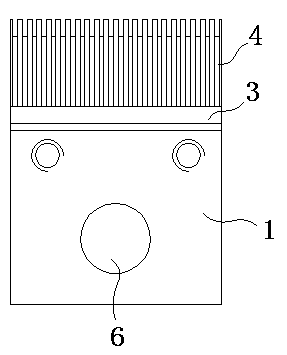

[0033] A built-in detachable movable main needle holder, such as figure 1 and 3 As shown, it includes a positioning block 1 made of MB2 type magnesium-aluminum alloy and a pressing block 2 made of MB2 type magnesium-aluminum alloy. The positioning block 1 and pressing block 2 are detachably connected by screws and can be flexibly disassembled; Between the block 1 and the pressing block 2 there is a space for accommodating and fixing a plurality of main needles 5, needle bodies 9 and pins 7, and a rubber sheet 8 is provided on the pressing surface of the pressing block 2; wherein the positioning block 1 is directly There is a horizontal positioning groove 3 for placing the pin 7 of the main needle 5, and a plurality of insertion grooves 4 longitudinally arranged for embedding the needle body 9 of the main needle 5 are arranged at the front of the positioning block 1; the positioning groove 3 and the insertion groove 4 are connected and the groove depth of the positioning groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com