Deep-layer dense multi-branch pile and application thereof

A branch pile and dense technology, which is applied to deep dense multi-branch piles and its application fields, can solve the problems of difficult pile length consistency, increase construction procedures, and reduce reliability, so as to increase the side surface area of the pile body and improve the pile side surface area. Friction, the effect of increasing the vertical bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

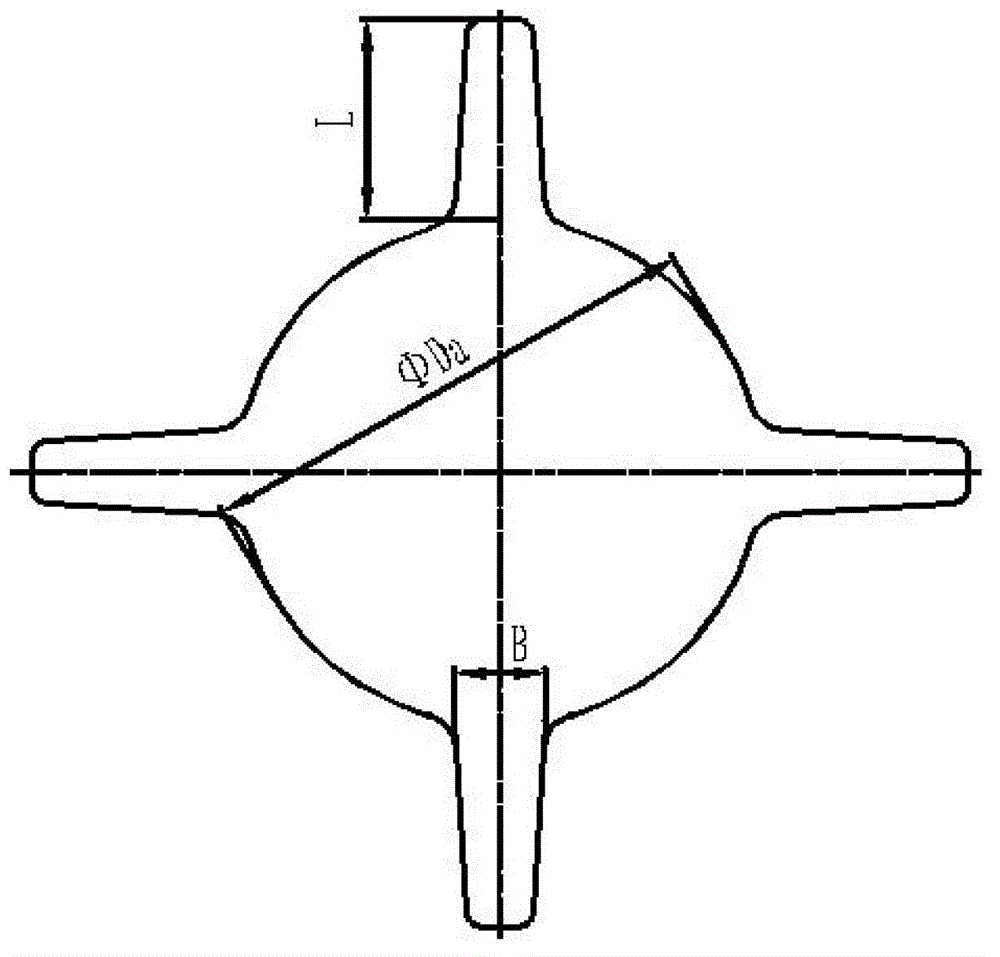

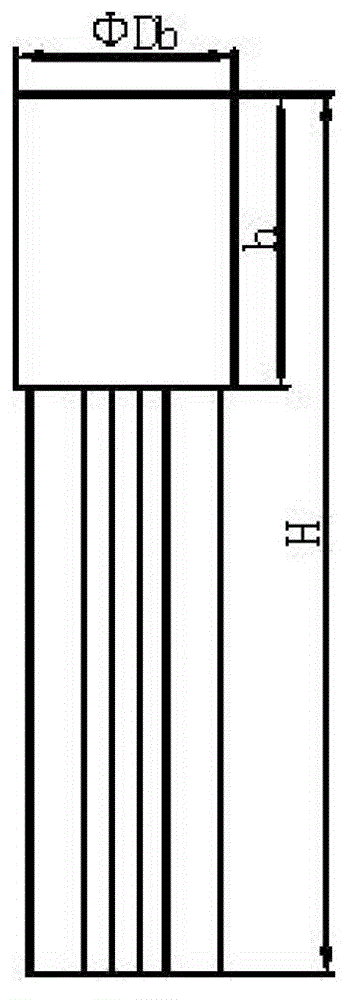

[0034] A deep dense multi-branch pile, comprising a columnar main body and sheet-like branches, and the sheet-like branches are arranged around the columnar main body, wherein, the length direction of the pile body is segmented or not segmented, and segmented The upper pile body of the pile body is a variable-diameter regulation bearing capacity section, and the lower pile body is a multi-branch section.

[0035] Wherein, the main parameters of the cross-section of the pile body include the diameter of the columnar main body ΦDa, the length L of the sheet-like branches, the width B of the sheet-like branches, and the number n of the sheet-like branches, and the main parameters of the pile body in the sub-sections include variable diameter Segment diameter ΦDb, pile body length H, variable diameter segment length h.

[0036] Among them, the diameter of the columnar body ΦDa ranges from Φ250 to Φ600 mm; the length of the sheet-like branches L ranges from 150 to 450 mm; the width...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com