Combustor box body device with stepping air mixing function

A burner, step-by-step technology, used in burners, gas fuel burners, combustion methods, etc., can solve the problems of flame pulling, partial burning, product performance degradation, etc., and achieve uniform gas mixture and high radiation function. , The effect of not easy to leak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

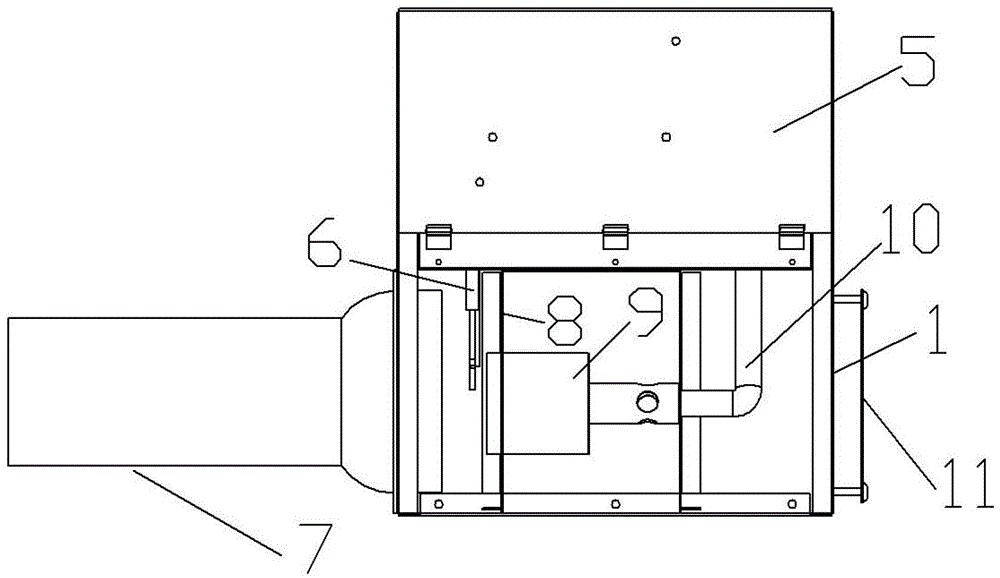

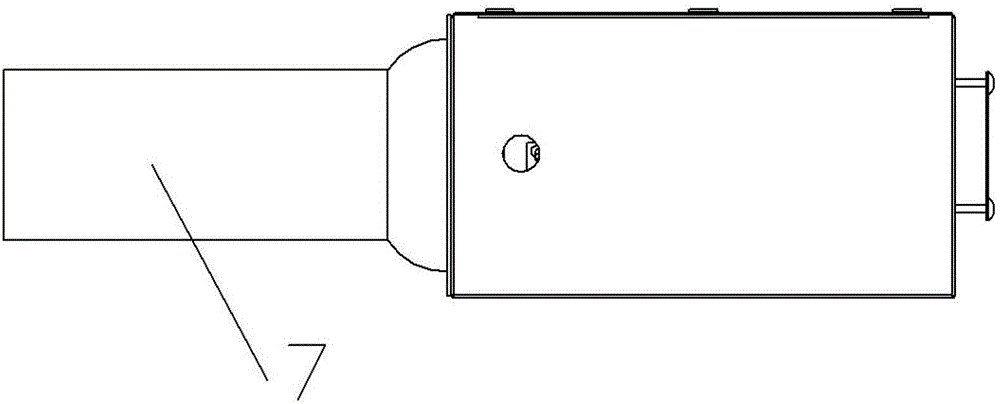

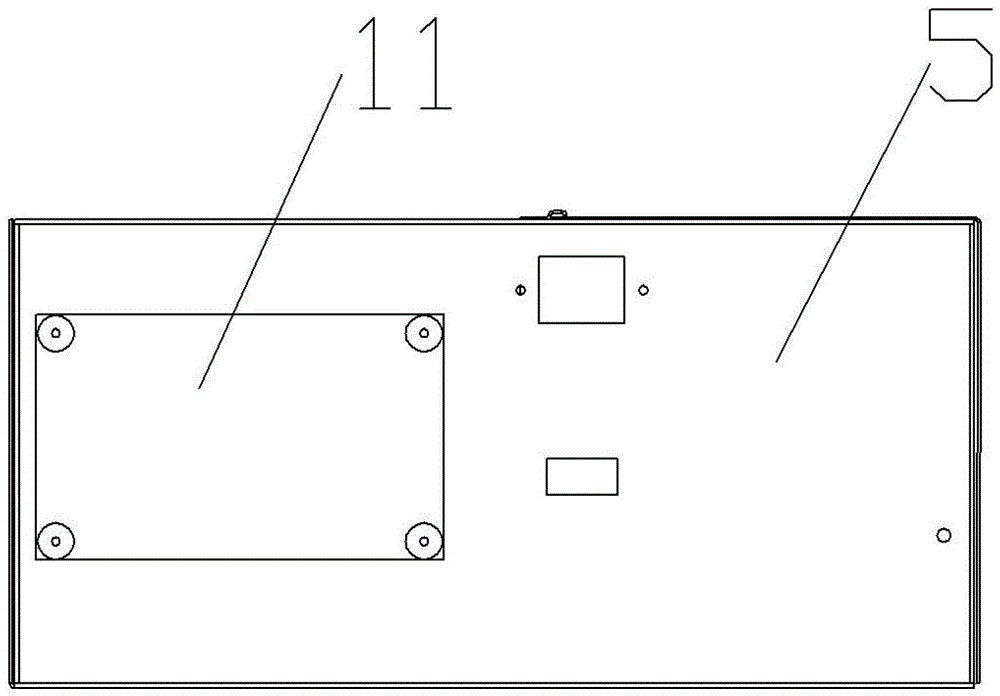

[0023] An embodiment of a burner box device with a step-by-step air mixing function, in Figure 1~6 Among them, the combustion box is a square airtight box, in order to see the internal structure clearly figure 1 and Figure 4 One side of the square airtight box is removed, and three section compartments 8 are fixedly arranged in the square airtight box 1. The three section compartments 8 have a first vertical plate 12 and a second vertical plate 13 parallel to each other. The plates are all parallel to the two opposite side walls of the square airtight box body 1, while the first vertical plate 12 and the second vertical plate 13 divide the square airtight box body 1 into three independent viewing spaces. An air mixer 9 is arranged between the second vertical plate 13. The air mixer 9 here is in the shape of a stepped sleeve, and its outer peripheral surface and inner hole of the air mixer 9 are stepped, that is, the outer peripheral surface is stepped. shaft, the inner hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com