High-precision position detection device and method

A detection device and high-precision technology, applied in the field of optical detection, can solve the problems of increasing equipment size, increasing equipment cost, reducing equipment reliability, etc., and achieve the effect of high measurement accuracy and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

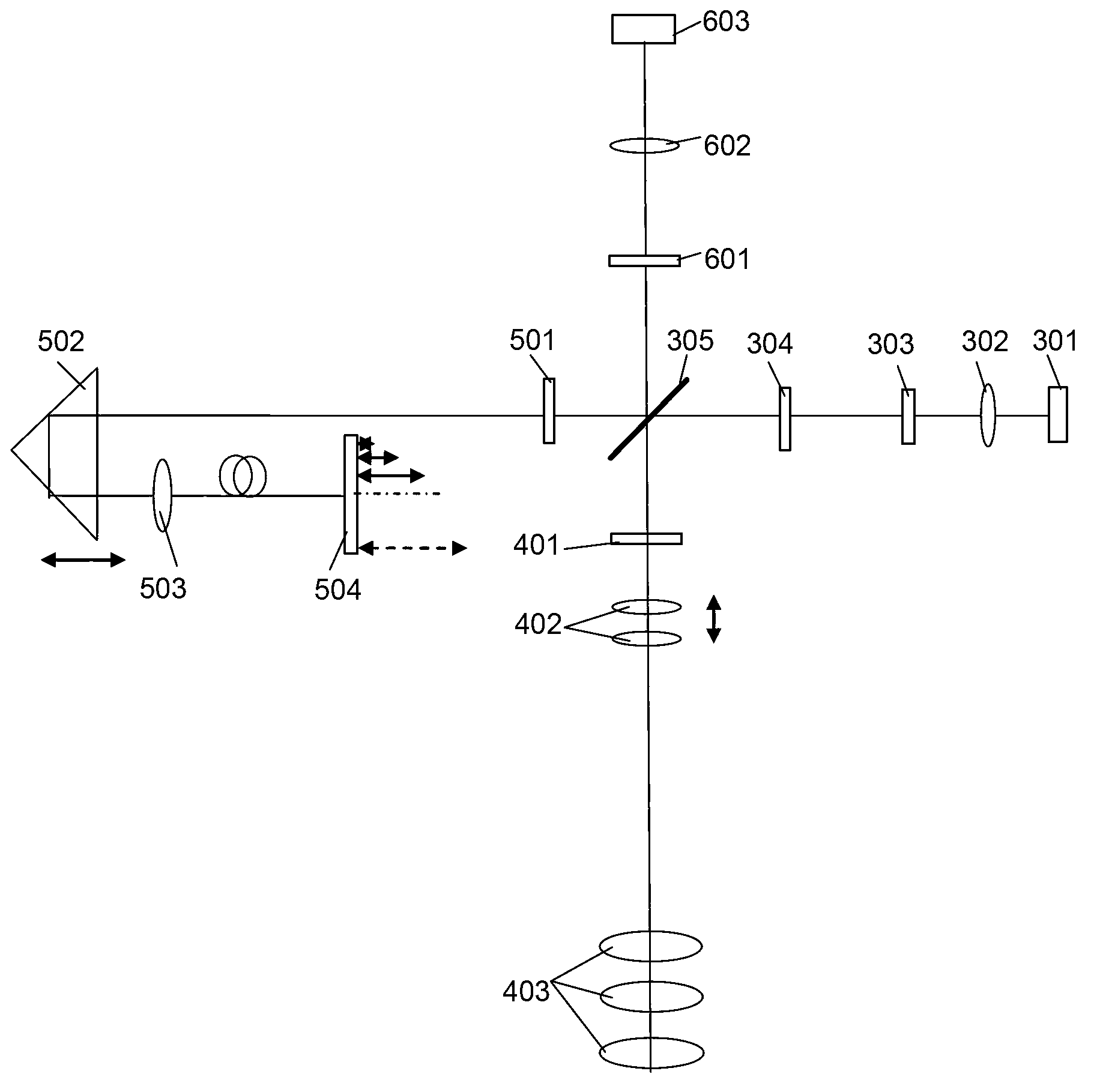

[0051] Such as figure 2 As shown in the structure diagram of the detection device of the present invention, the short coherent light source 301 passes through the collimator lens 302, becomes parallel light, passes through the polarizer 303 and the 1 / 2 wave plate 304, and enters the polarization beam splitter in a certain polarization direction 305, after passing through the beam splitter, a beam of light is transmitted, and after passing through the first 1 / 4 wave plate 501, it enters a movable total reflection mirror 502, and the light emitted from the total reflection mirror 502 passes through a coupling lens 503 to couple the light to In an end-reflection fiber optic beam splitter 504, the end-reflection fiber optic beam splitter 504 is a 1×n beam splitter, which divides one path of light into n paths of light, and there are different optical path differences between the n paths of light. The end of each fiber branch is coated with a reflective film, and the reflected lig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coherence length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com