Self-balancing motorized spindle comprehensive performance test platform

A test platform and comprehensive performance technology, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve the problems of complex structure, lack of measurement scheme, lack of vibration control measures, etc., and achieve the effect of simple scheme

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

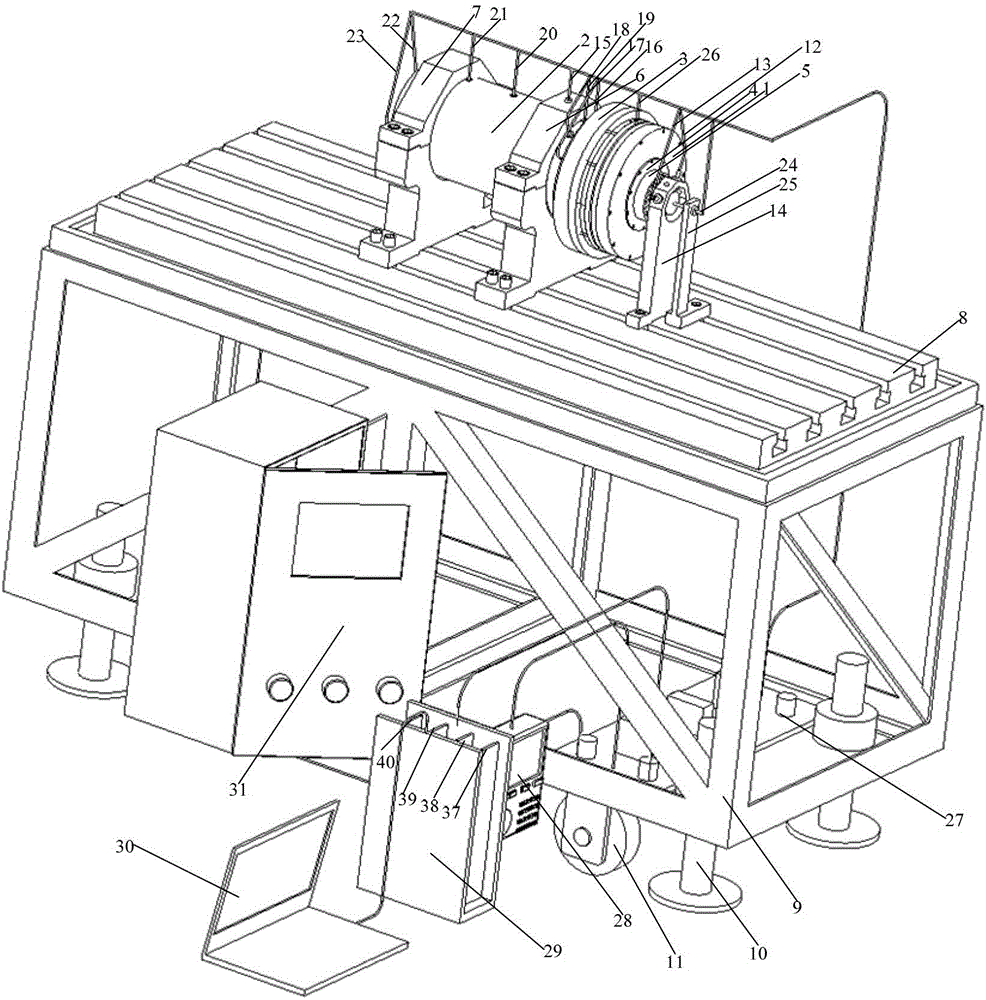

[0037] see Figure 1 to Figure 4 , the present invention provides a self-balancing electric spindle comprehensive performance test platform, including a self-balancing electric spindle and its support system, a sensor and its support system, a state monitoring and automatic balancing system, an automatic alarm and an active control stop system;

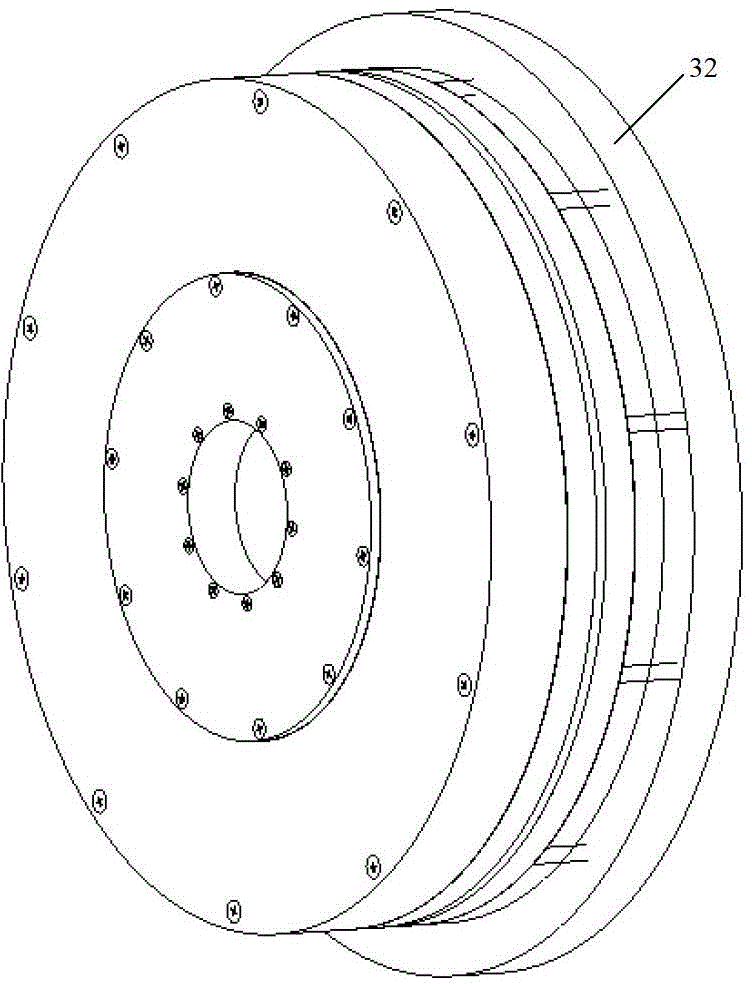

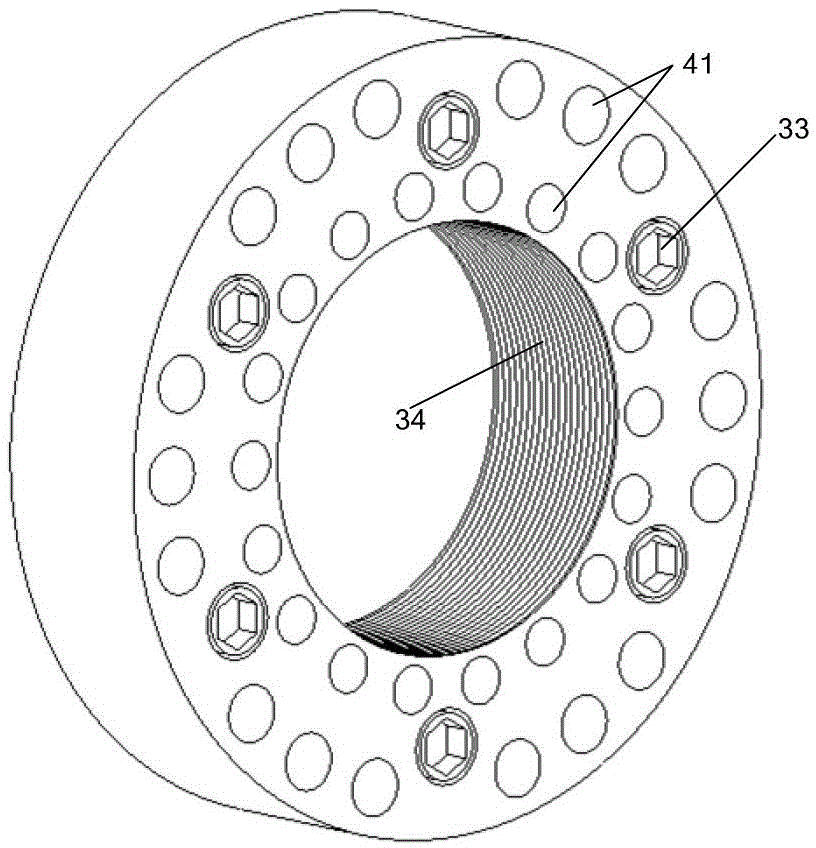

[0038] The self-balancing electric spindle and its supporting system include the electric spindle 2 and the test bench support 9 with a slot on the top surface, and the front end of the electric spindle 2 is equipped with a balancing head and an unbalanced simulation disk for fixing the balancing head 5. The electric spindle 2 is fixed on the T-shaped table 8 through the front bearing seat 6 and the rear bearing seat 7, and the T-shaped table 8 is pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com