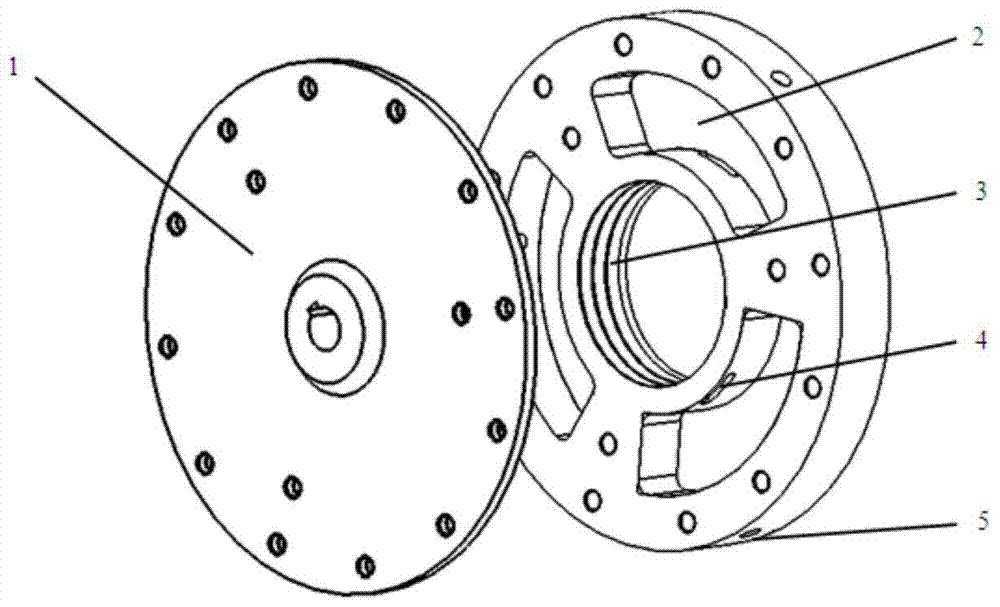

A Liquid Injection and Drainage Online Dynamic Balancing Head Structure for High Rotational Speeds

A technology of liquid injection and drainage, high speed, applied in the field of dynamic balance, can solve the problems of high cost, lack of balance ability, poor safety, etc., and achieve the effect of high safety, strong practicability, and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

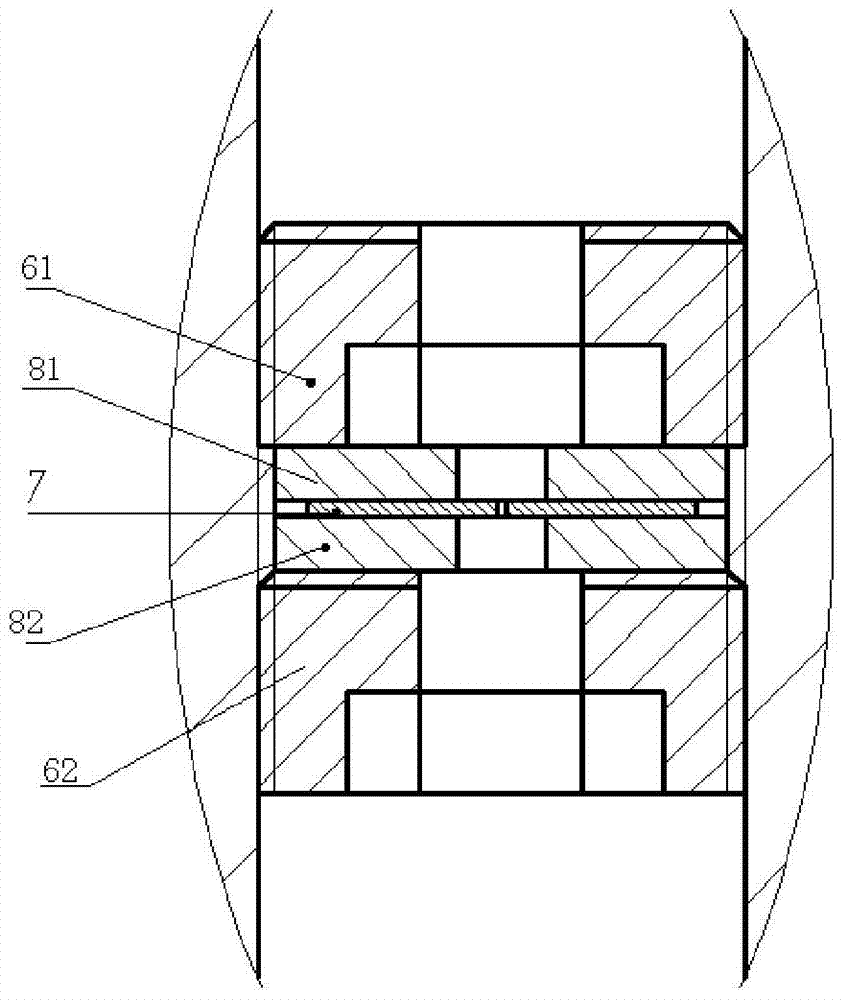

Embodiment 1

[0025] The inner wall of the second through hole 5 is provided with an internal thread, and the throttle valve includes a first hexagon socket bolt 61, a first gasket 81, a sheet 7, a first hexagonal socket bolt 61, a first gasket 81, a sheet 7, and a second through hole 5 sequentially arranged in the second through hole 5 from the inside to the outside. Two gaskets 82 and the second hexagon socket bolt 62, and the middle part of the first gasket 81 and the second gasket 82 are all provided with the 3rd through hole, the middle part of sheet 7 is provided with the 4th through hole, the 4th through hole and The third through hole, the through hole in the middle of the first hexagon socket bolt 61 and the through hole in the second hexagon socket bolt 62 are connected, and on the outer wall of the first hexagon socket bolt 61 and on the outer wall of the second hexagon socket bolt 62 An external thread matched with the internal bolt is provided.

[0026] The flow rate of the liq...

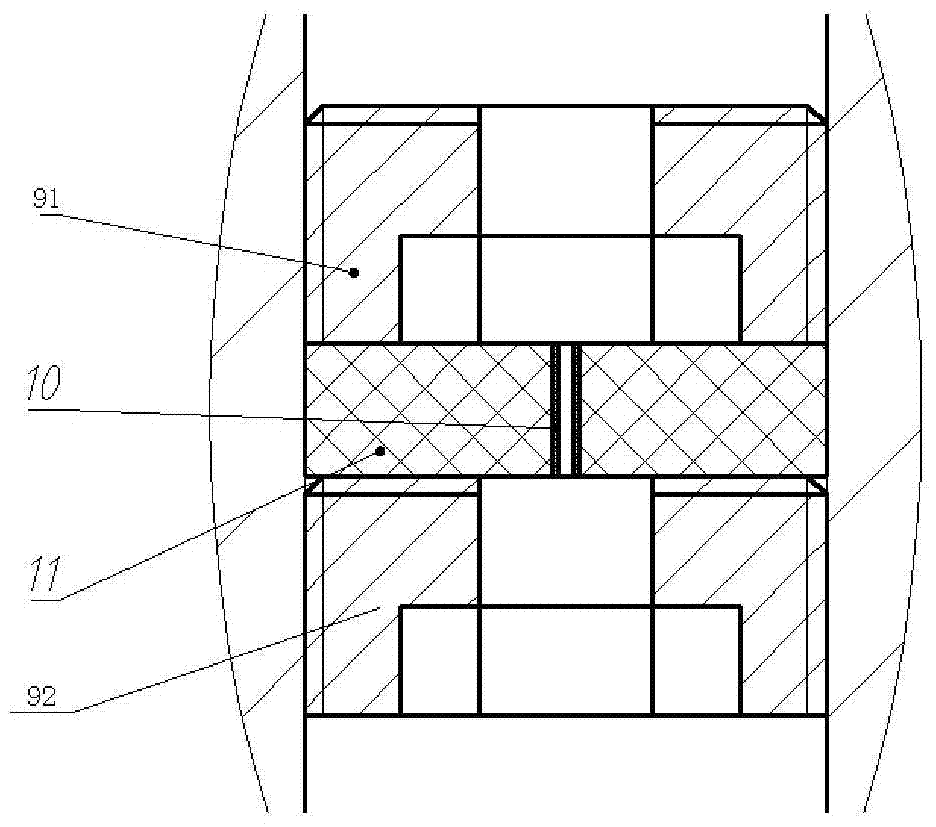

Embodiment 2

[0028] The inner wall of the second through hole 5 is provided with an internal thread, and the throttle valve includes a third hexagon socket bolt 91, a rubber sheet 11 and a fourth hexagon socket bolt 92 which are sequentially arranged in the second through hole 5 from the inside to the outside. , and the fifth through hole 10 on the rubber sheet 11, the fifth through hole 10 communicates with the through hole in the middle of the third inner hexagon bolt 91 and the through hole in the middle of the fourth inner hexagon bolt 92, the outer wall of the third inner hexagon bolt 91 External threads matching the internal threads are provided on the upper and outer walls of the fourth hexagon socket head bolt 92 .

[0029] Then the flow rate of the liquid flowing out of the throttle valve is Wherein Δp is the pressure difference between the empty inlet and outlet of the fifth through hole 10, d is the inner diameter of the fifth through hole 10, μ is the dynamic viscosity of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com