An online detection system and method for the density of latex matrix and finished emulsion explosives

An emulsion explosive and latex matrix technology, applied in the field of civil explosives, can solve the problem of data not being able to be fed back in time, and achieve the effect of reducing online staff, measuring fast and accurate, and improving industry intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments:

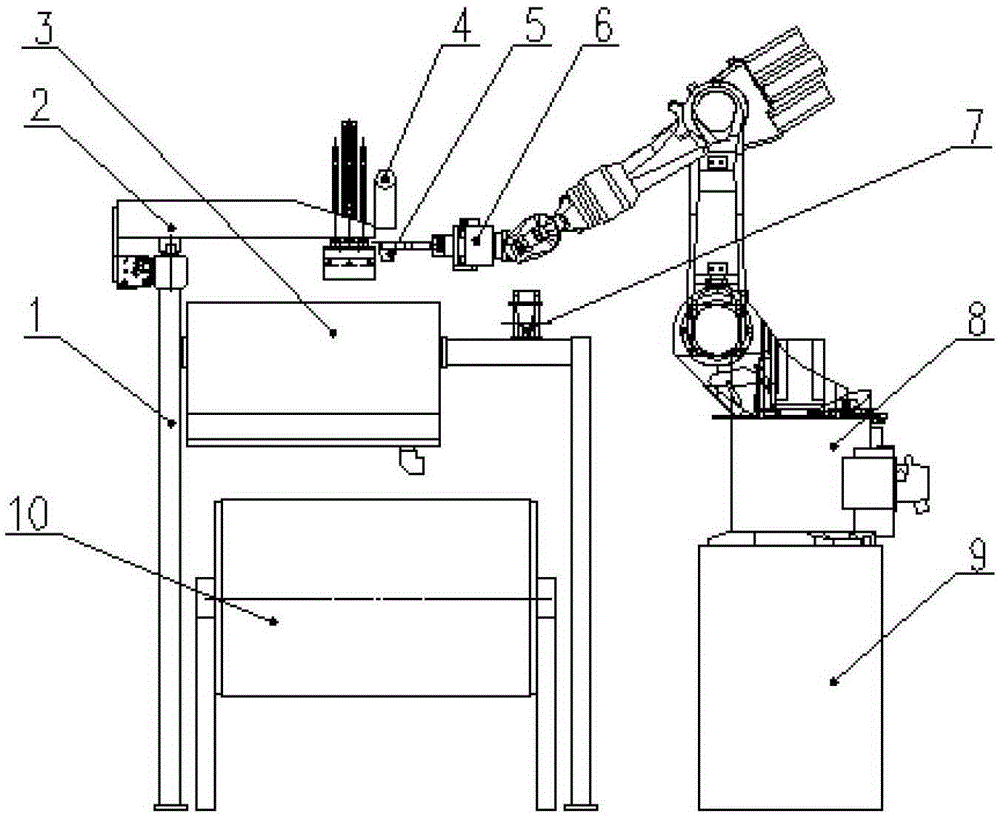

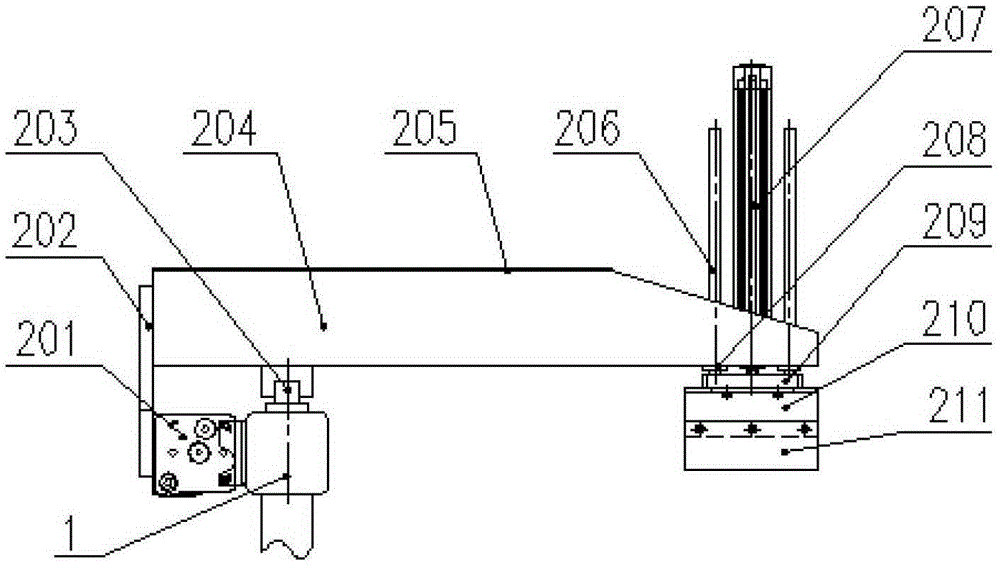

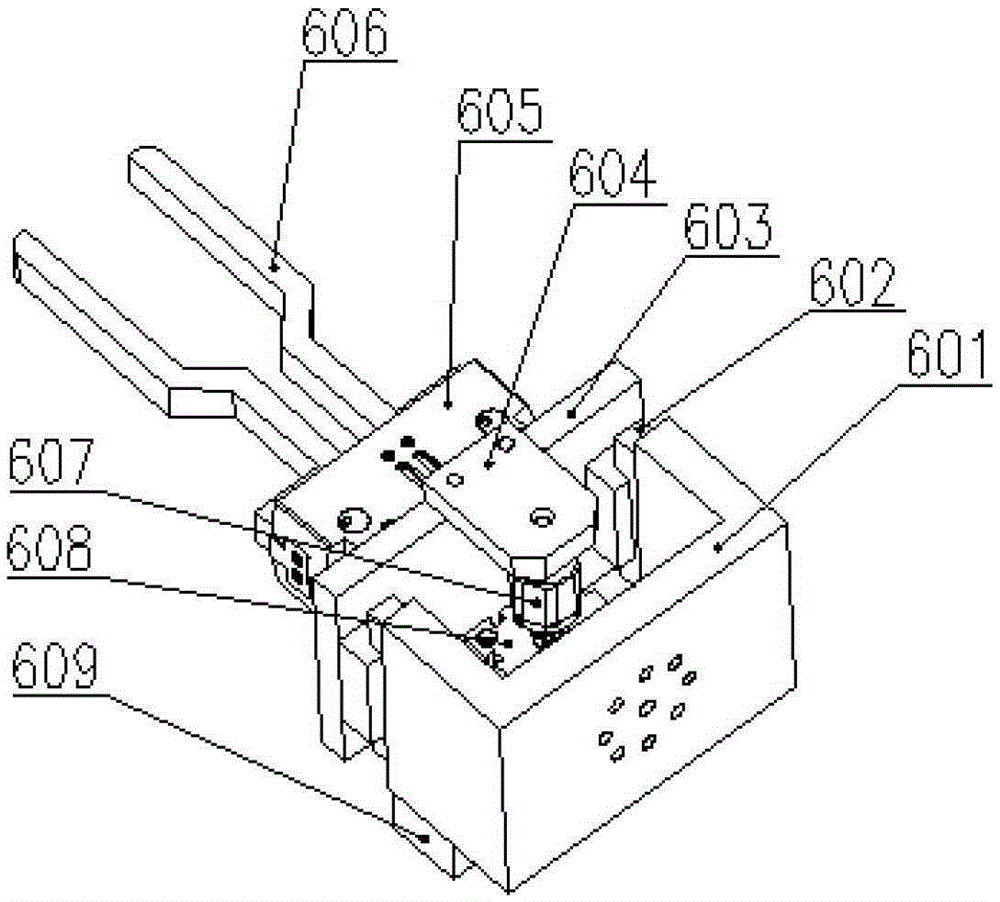

[0033] Please refer to figure 1 , the present invention provides an on-line detection system and method for the density of latex matrix and finished emulsion explosives, which is used in the production line of industrial emulsion explosives, including a frame 1, an industrial robot 8, a matrix conveyor 10, a scraper mechanism 2, and a robot clamp 6 , a weighing device 7, a sampling container 5 and a computing device (not shown).

[0034] Please refer to figure 1 , the frame 1 is installed on the ground and arranged on the left and right sides of the matrix conveyor 10 .

[0035] Please refer to figure 1 , the industrial robot 8 is installed on the upper surface of the robot base 9 , the robot base 9 is connected to the ground and is located on the side of the matrix conveyor 10 .

[0036] Please refer to fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com