Carbon nano-tube ionization self-resonance type gas sensitive sensor

A gas sensor and carbon nanotube technology, applied in the field of gas sensors, can solve the problems of few types of detected gases, slow response speed, low repeatability, etc. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

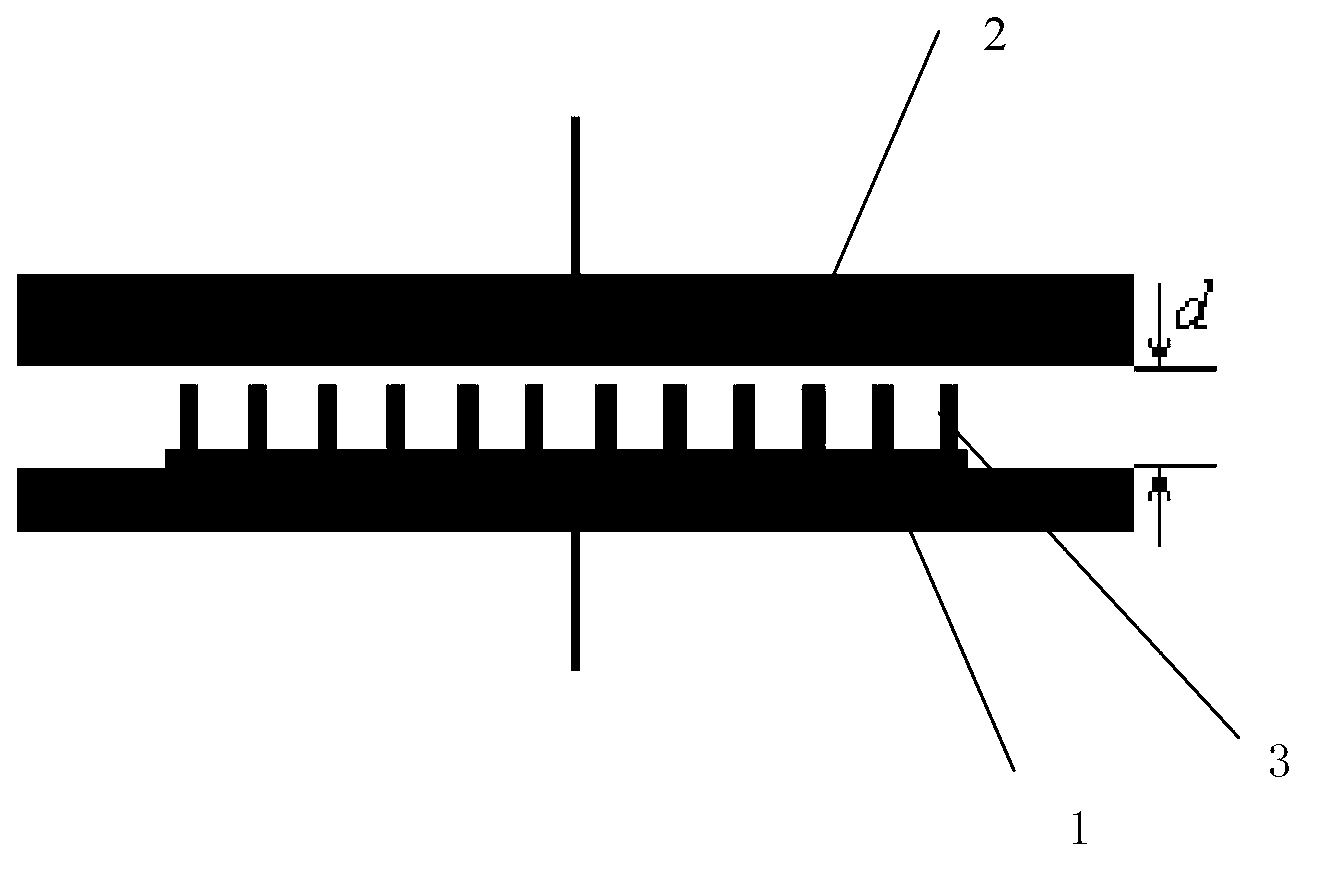

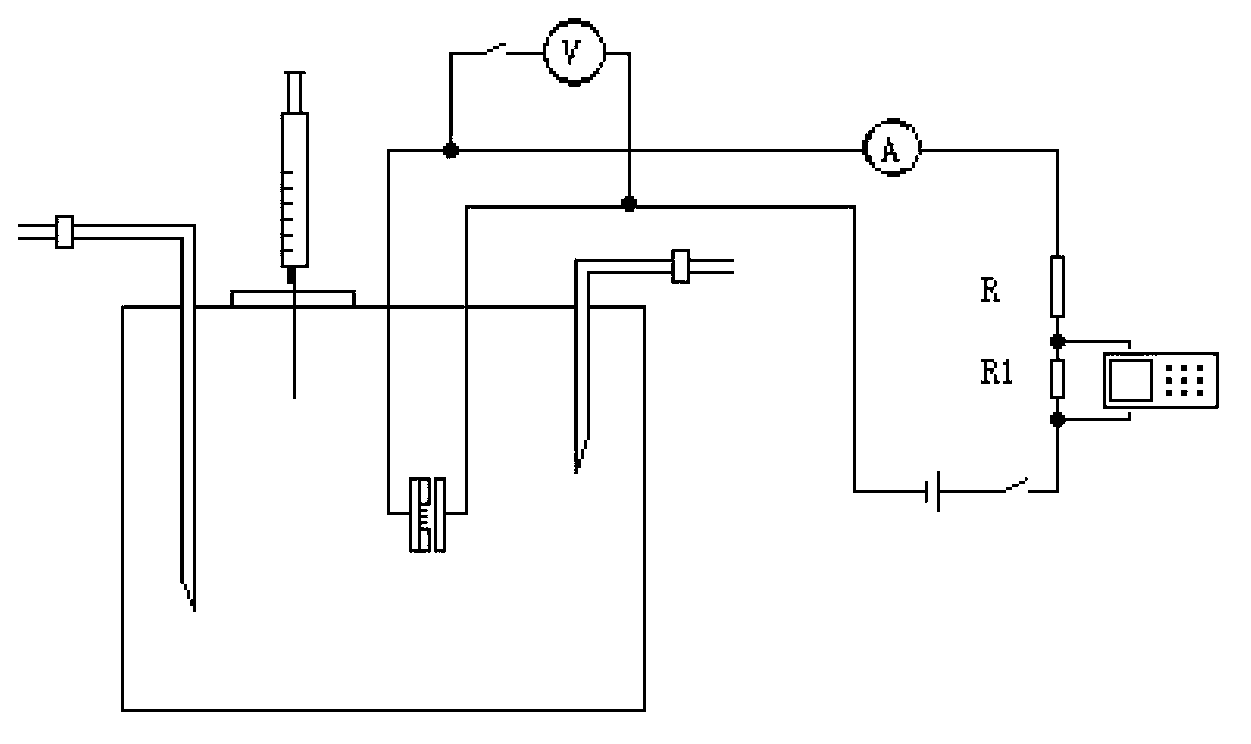

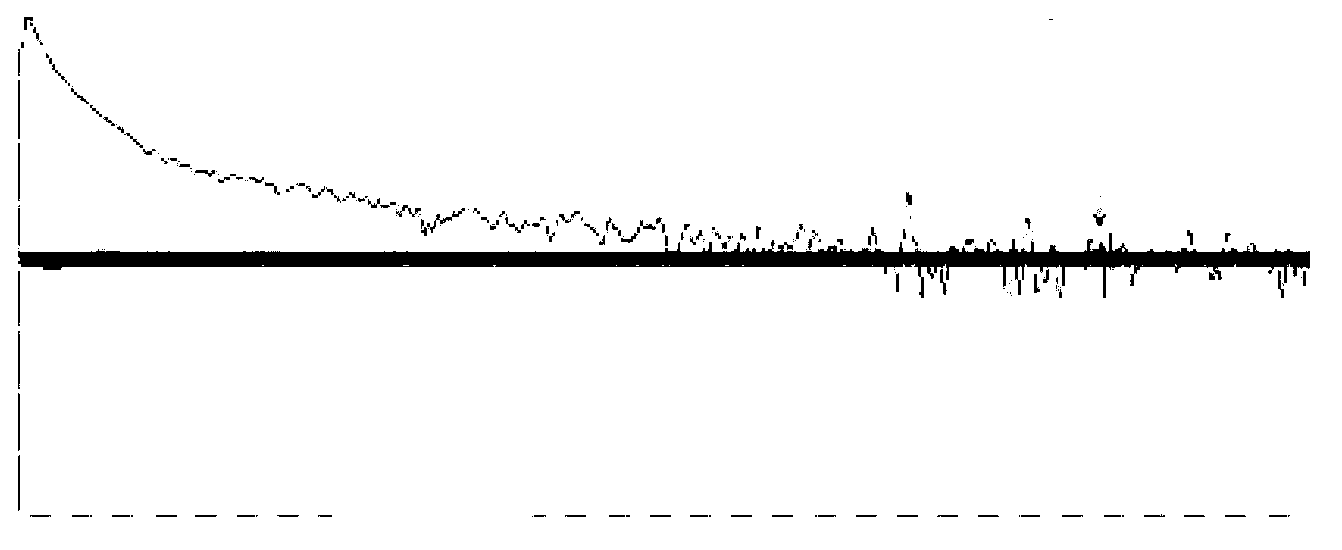

[0015] refer to Figure 1 to Figure 5 , a carbon nanotube ionization self-resonance type gas sensor, comprising a carbon nanotube electrode 1, an aluminum plate electrode 2 and an insulating film 3, the carbon nanotube electrode 1 is covered with the insulating film 3, and the insulating film 3 is covered There is a row of grooves corresponding to the polarity distribution of different gases, and the insulating film 3 is covered with an aluminum plate electrode 2; a bias voltage generating device is connected between the carbon nanotube electrode 1 and the aluminum plate electrode 2, and the gas sensor The sensor also includes a noise generating device for generating noises of various stochastic resonance strengths and a gas recognition device for real-time recording of voltage-current detection data after multiple stochastic resonances are induced, and pattern recogni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com